Toyota Sienna Service Manual: Actuator Supply Voltage Circuit / Open

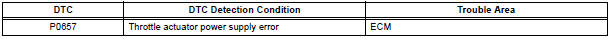

DTC P0657 Actuator Supply Voltage Circuit / Open

DESCRIPTION

The ECM monitors the output voltage to the throttle actuator. This self-check ensures that the ECM is functioning properly. The output voltage is usually 0 V when the ignition switch is turned off. If the output voltage is higher than 7 volts when the ignition switch is turned off, the ECM will illuminate the MIL and set a DTC when the ignition switch is turned on.

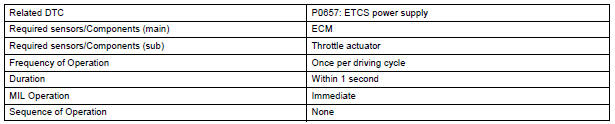

MONITOR STRATEGY

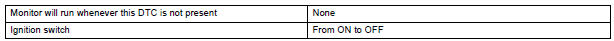

TYPICAL ENABLING CONDITIONS

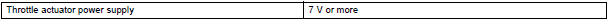

TYPICAL MALFUNCTION THRESHOLDS

INSPECTION PROCEDURE

1 CHECK WHETHER DTC OUTPUT RECURS (IN ADDITION TO DTC P0657)

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to the ON position.

- Turn the tester on.

- Clear the DTC.

- Turn the ignition switch off.

- Disconnect the battery negative terminal and wait for 1 minute.

- Connect the battery negative terminal.

- Turn the ignition switch to the ON position for 10 seconds.

- Turn the ignition switch off.

- Turn the ignition switch to the ON position.

- Enter the following menus: DIAGNOSIS / ENHANCED II / DTC INFO / CURRENT CODES.

- Read the DTCs.

Result

REPLACE ECM

VIN not Programmed or Mismatch - ECM / PCM

VIN not Programmed or Mismatch - ECM / PCM

DTC P0630 VIN not Programmed or Mismatch - ECM / PCM

DESCRIPTION

DTC P0630 is set when the Vehicle Identification Number (VIN) is not stored

in the Engine Control Module

(ECM) or the input VIN is ...

Transmission Range Sensor Circuit Malfunction

(PRNDL Input)

Transmission Range Sensor Circuit Malfunction

(PRNDL Input)

DTC P0705 Transmission Range Sensor Circuit Malfunction

(PRNDL Input)

DESCRIPTION

The park/neutral position switch detects the shift lever position and sends

signals to the ECM.

HINT:

After ...

Other materials:

Receiving a message

When an e-mail/SMS/MMS is received, the incoming message screen

pops up with sound and is ready to be operated on the screen.

Select to check the message.

Select to refuse the message.

Select to call the message

sender.

Receiving a message

Depending on the cellular phone used f ...

Installation

1. INSTALL CHARCOAL CANISTER ASSEMBLY

(a) Install the 3 bolts and charcoal canister.

Torque: 29 N*m (296 kgf*cm, 21 ft.*lbf)

(b) Connect the purge line hose to the charcoal

canister.

(c) Connect the wire harness clamp.

(d) Connect the vapor pressure sensor connector.

(e) Connect t ...

Error in Picture Circuit/ No Current in Back-light/ Excess Current in

Back-light

DTC 34-10 Error in Picture Circuit

DTC 34-11 No Current in Back-light

DTC 34-12 Excess Current in Back-light

DESCRIPTION

DTC No.

DTC Detection Condition

Trouble Area

34-10

Error in power supply system for picture circuit

Radio and navigation assembly

...