Toyota Sienna Service Manual: Vvt sensor

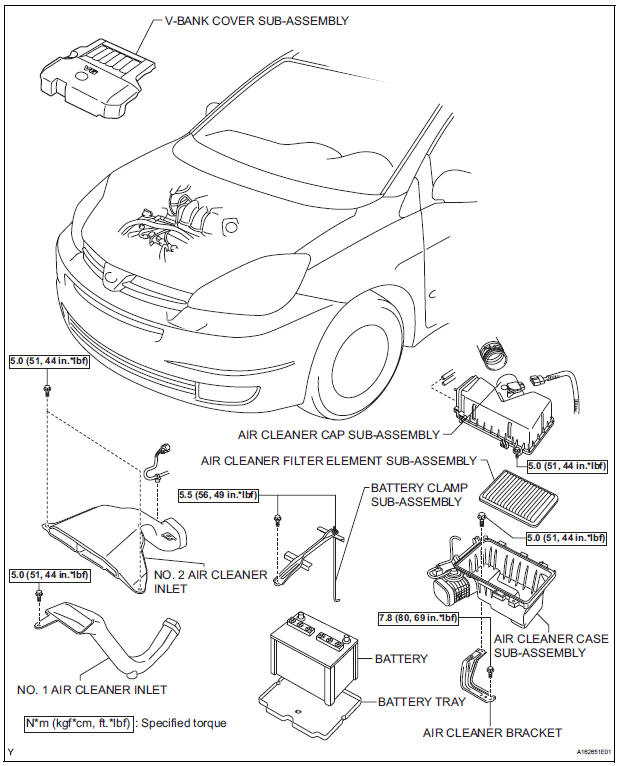

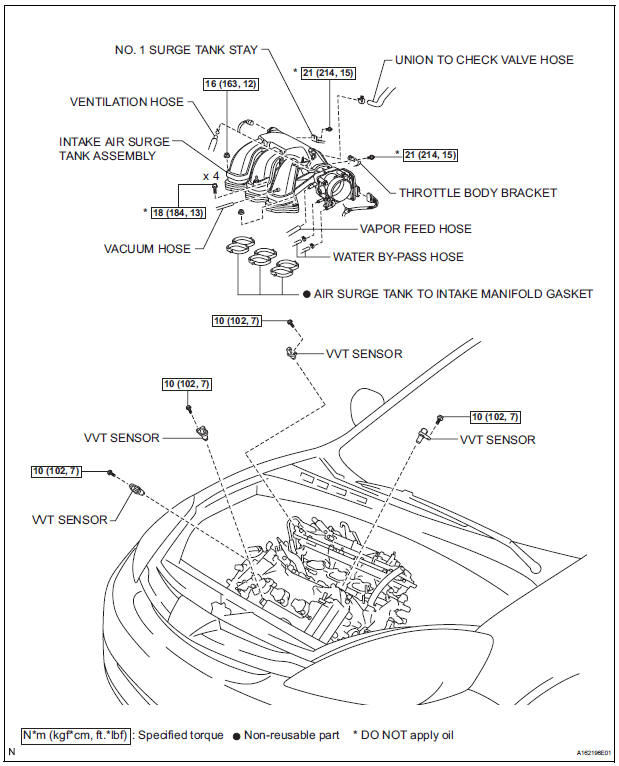

COMPONENTS

ON-VEHICLE INSPECTION

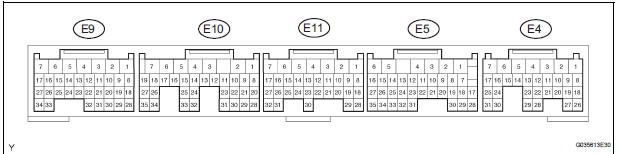

1. CHECK VVT SENSOR OUTPUT VOLTAGE

(a) Turn the ignition switch to the ON position.

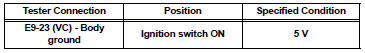

(b) Check the voltage between the specified terminal and body ground.

Standard voltage

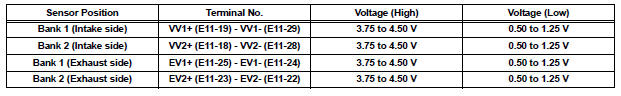

(c) While turning the crankshaft pulley by hand, measure the voltage between each terminal. Check that the voltage changes between the High range and Low range shown in the table below.

Standard voltage

REMOVAL

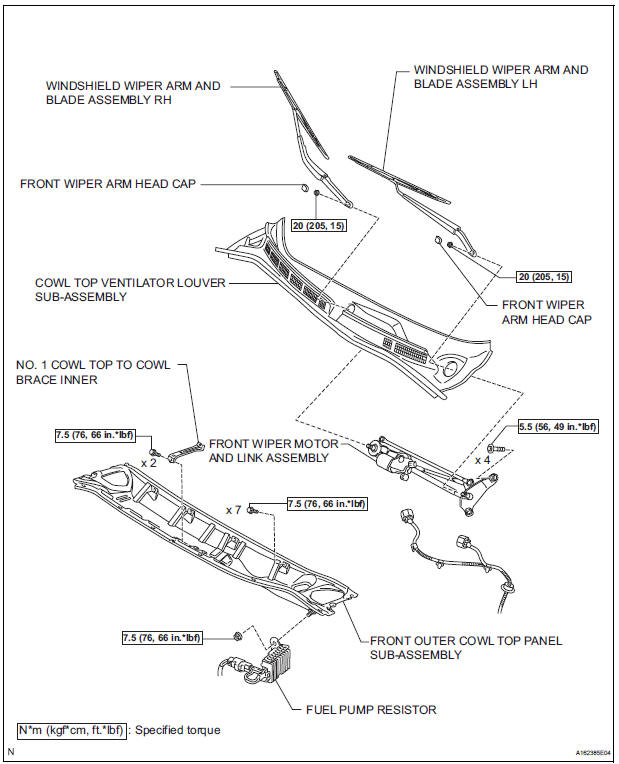

1. REMOVE WINDSHIELD WIPER MOTOR ASSEMBLY HINT: (See page WW-4) 2. REMOVE FRONT OUTER COWL TOP PANEL SUBASSEMBLY (See page EM-27) 3. DRAIN ENGINE COOLANT (See page CO-6) 4. REMOVE V-BANK COVER SUB-ASSEMBLY (See page EM-28) 5. REMOVE NO. 2 AIR CLEANER INLET (See page EM- 28) 6. REMOVE NO. 1 AIR CLEANER INLET (See page EM- 28) 7. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See page ES-493) 8. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See page EM-28) 9. REMOVE INTAKE AIR SURGE TANK ASSEMBLY (See page ES-521) 10. REMOVE VVT SENSOR (for Bank 1 Intake Side)

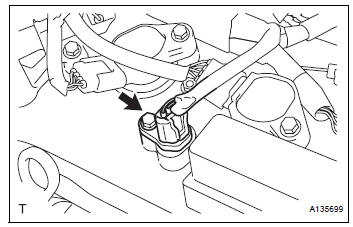

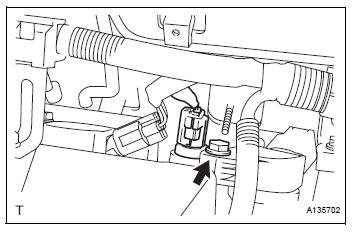

(a) Disconnect the VVT sensor connector.

(b) Remove the bolt and VVT sensor.

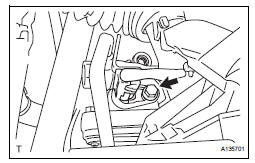

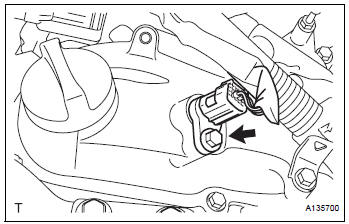

11. REMOVE VVT SENSOR (for Bank 1 Exhaust Side)

(a) Disconnect the VVT sensor connector.

(b) Remove the bolt and VVT sensor.

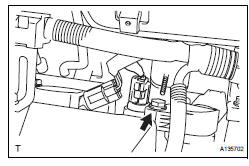

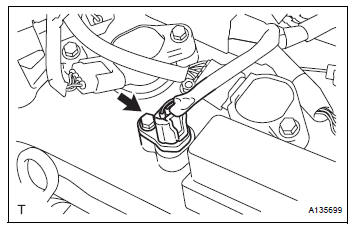

12. REMOVE VVT SENSOR (for Bank 2 Intake Side)

(a) Disconnect the VVT sensor connector.

(b) Remove the bolt and VVT sensor.

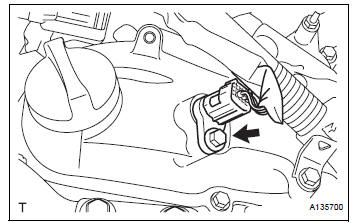

13. REMOVE VVT SENSOR (for Bank 2 Exhaust Side)

(a) Disconnect the VVT sensor connector.

(b) Remove the bolt and VVT sensor.

INSTALLATION

1. INSTALL VVT SENSOR (for Bank 2 Exhaust Side)

(a) Install the VVT sensor with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf) (b) Connect the VVT sensor connector.

2. INSTALL VVT SENSOR (for Bank 2 Intake Side)

(a) Install the VVT sensor with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf) (b) Connect the VVT sensor connector.

3. INSTALL VVT SENSOR (for Bank 1 Exhaust Side)

(a) Install the VVT sensor with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf) (b) Connect the VVT sensor connector.

4. INSTALL VVT SENSOR (for Bank 1 Intake Side)

(a) Install the VVT sensor with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf) (b) Connect the VVT sensor connector.

5. INSTALL INTAKE AIR SURGE TANK ASSEMBLY (See page ES-522) 6. INSTALL AIR CLEANER CASE SUB-ASSEMBLY (See page EM-59) 7. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (See page ES-496) 8. INSTALL NO. 1 AIR CLEANER INLET (See page EM- 59) 9. INSTALL NO. 2 AIR CLEANER INLET (See page EM- 60) 10. ADD ENGINE COOLANT (See page CO-7) 11. INSPECT FOR ENGINE COOLANT LEAK (See page CO-1) 12. INSPECT FOR ENGINE OIL LEAK (See page LU-6) 13. INSTALL V-BANK COVER SUB-ASSEMBLY (See page EM-63) 14. INSTALL FRONT OUTER COWL TOP PANEL SUBASSEMBLY (See page EM-61) 15. INSTALL WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-5)

Mass air flow meter

Mass air flow meter

COMPONENTS

ON-VEHICLE INSPECTION

1. INSPECT MASS AIR FLOW METER

NOTICE:

Perform the mass air flow (MAF) meter inspection

by following the procedures below.

Only replace t ...

Crankshaft position sensor

Crankshaft position sensor

Components

Removal

1. Remove compressor and magnetic clutch

HINT:

(See page AC-227 )

2. REMOVE CRANKSHAFT POSITION SENSOR

(a) Disconnect the crankshaft position sensor

connector.

(b) R ...

Other materials:

Components

...

Inspection

1. INSPECT FRONT SEAT INNER BELT ASSEMBLY RH

Release the seat belt (Buckle switch is ON).

Check the resistance between the terminals.

Standard

If the result is not as specified, replace the inner belt

assembly.

Inspect the buckle switch.

Fasten ...

Short to GND in Rear Curtain Shield Squib LH

Circuit

DTC B1637/85 Short to GND in Rear Curtain Shield Squib LH

Circuit

DESCRIPTION

The rear curtain shield squib LH circuit consists of the center airbag sensor

assembly and the curtain

shield airbag assembly LH.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC ...