Toyota Sienna Service Manual: ECM

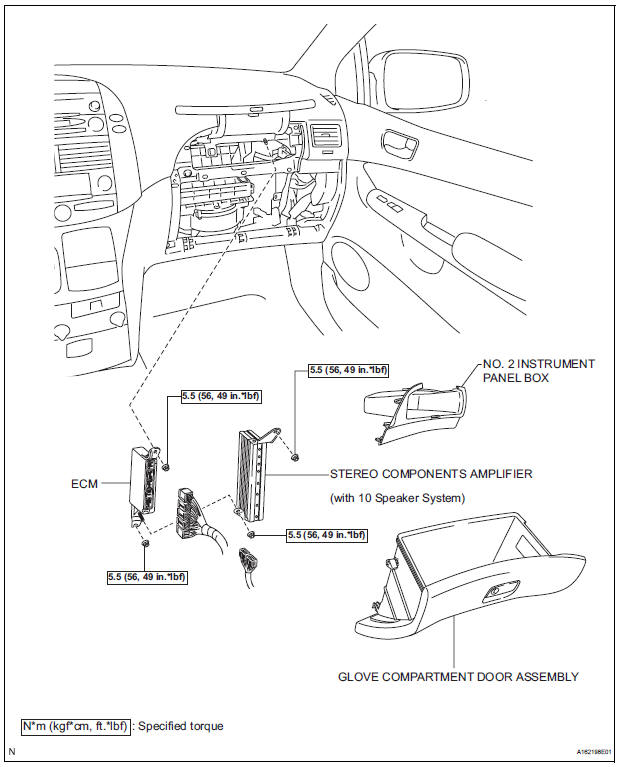

COMPONENTS

REMOVAL

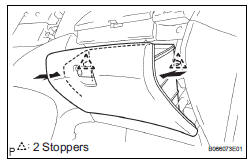

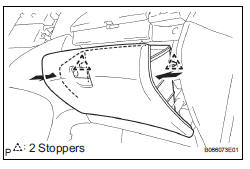

1. REMOVE GLOVE COMPARTMENT DOOR ASSEMBLY

(a) Push the right side wall and then push the left wall to release the stoppers.

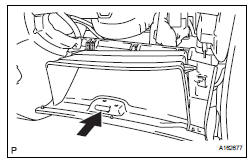

(b) Pull the glove compartment door sub-assembly rearward to remove it.

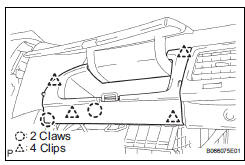

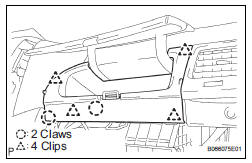

2. REMOVE NO. 2 INSTRUMENT PANEL BOX

(a) Disengage the 2 claws and 4 clips, and remove the No. 2 instrument panel box.

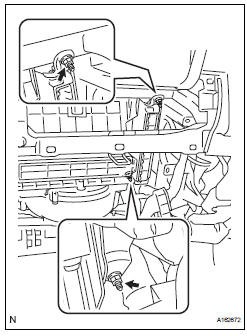

3. REMOVE ECM

(a) Disconnect the 5 ECM connectors.

(b) Remove the 2 nuts and ECM.

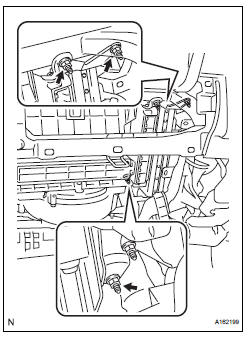

4. REMOVE ECM (with 10 speakers system)

(a) Disconnect the 5 ECM connectors and 2 stereo components amplifier connectors.

(b) Remove the 4 nuts and the ECM with the stereo components amplifier.

INSTALLATION

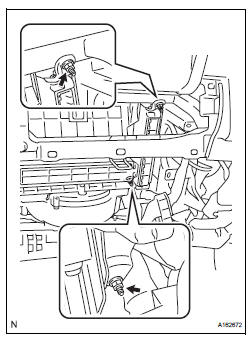

1. INSTALL ECM

(a) Install the ECM with the 2 nuts.

Torque: 5.5 N*m (56 kgf*cm, 49 in.*lbf) (b) Connect the 5 ECM connectors.

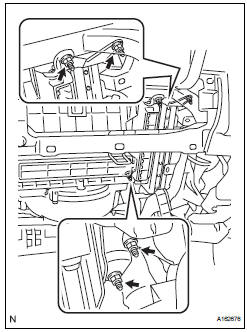

2. INSTALL ECM (with 10 speakers system)

(a) Install the ECM and stereo components amplifier with the 4 nuts.

Torque: 5.5 N*m (56 kgf*cm, 49 in.*lbf) (b) Connect the 5 ECM connectors and 2 stereo components amplifier connectors.

3.INSTALL NO. 2 INSTRUMENT PANEL BOX

(a) Install the No. 2 instrument panel box.

4. INSTALL GLOVE COMPARTMENT DOOR ASSEMBLY

(a) Install the glove compartment door sub-assembly frontward to install it.

(b) Push the right side wall and then push the left wall to install the stoppers.

5. PERFORM REGISTRATION

(a) When replacing the ECM, perform distance control ECU recognition in ECM (See page CC-125).

Installation

Installation

1. INSTALL THROTTLE BODY

(a) Install a new throttle body gasket to the intake air

surge tank.

(b) Install the throttle body with the 4 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

...

Accelerator pedal rod

Accelerator pedal rod

COMPONENTS

ON-VEHICLE INSPECTION

1. CHECK ACCELERATOR PEDAL ROD

(a) Check the voltage.

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

...

Other materials:

Disc cannot be Played/ No Playable Files/ Copyright Protection Error

DTC 63-7D Disc cannot be Played

DTC 63-7E No Playable Files

DTC 63-7F Copyright Protection Error

DESCRIPTION

DTC No.

DTC Detection Condition

Trouble Area

63-7D

An incompatible MP3 / WMA file is used.

Although the file has an extension of &quo ...

Short to GND in Front Passenger Side Squib

2nd Step Circuit

DTC B1187/55 Short to GND in Front Passenger Side Squib

2nd Step Circuit

DESCRIPTION

The front passenger side squib 2nd step circuit consists of the center airbag

sensor assembly and the

front passenger airbag assembly.

The circuit instructs the SRS to deploy when deployment conditions are ...

Canceling the rear moon roof operation (vehicles with the rear

moon roof)

Press the switch to disable the

rear moon roof operation from the

rear seat.

Pressing the switch again will

enable the operation again.

The moon roof can be operated when

The engine switch is in the “ON” position (vehicles without a smart key

system)

or IGNITION ON mode (vehicles ...