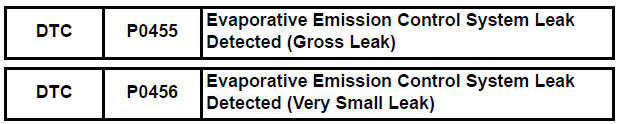

Toyota Sienna Service Manual: Evaporative Emission Control System Leak Detected

DTC SUMMARY

DESCRIPTION

The circuit description can be found in the EVAP (Evaporative Emission) System (See page ES-409).

INSPECTION PROCEDURE

Refer to the EVAP System (See page ES-412).

MONITOR DESCRIPTION

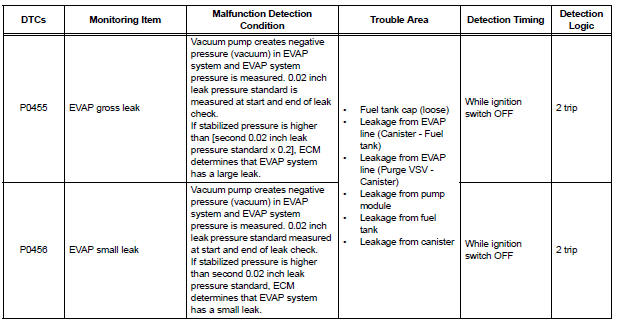

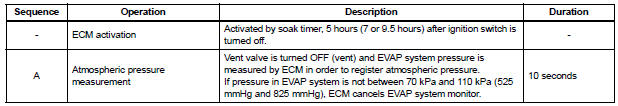

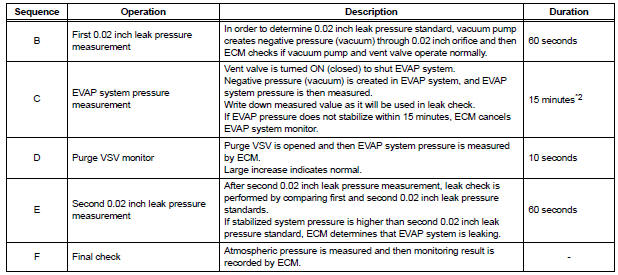

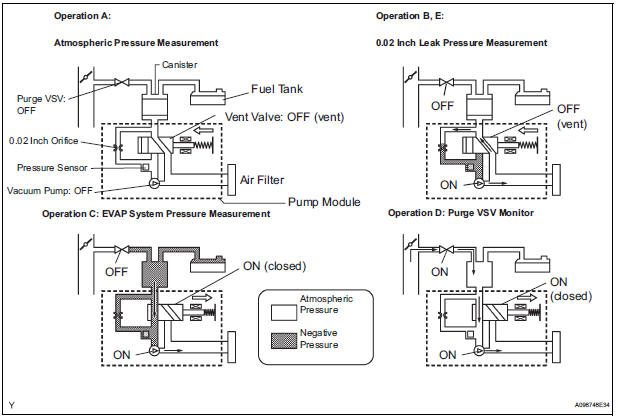

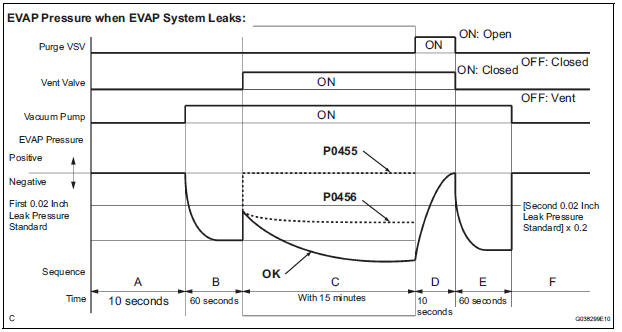

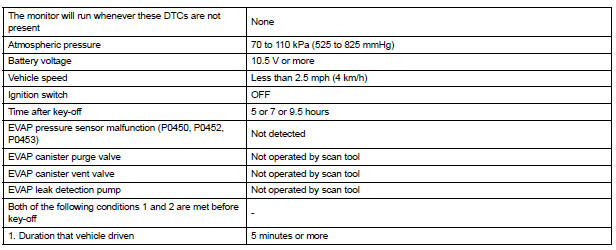

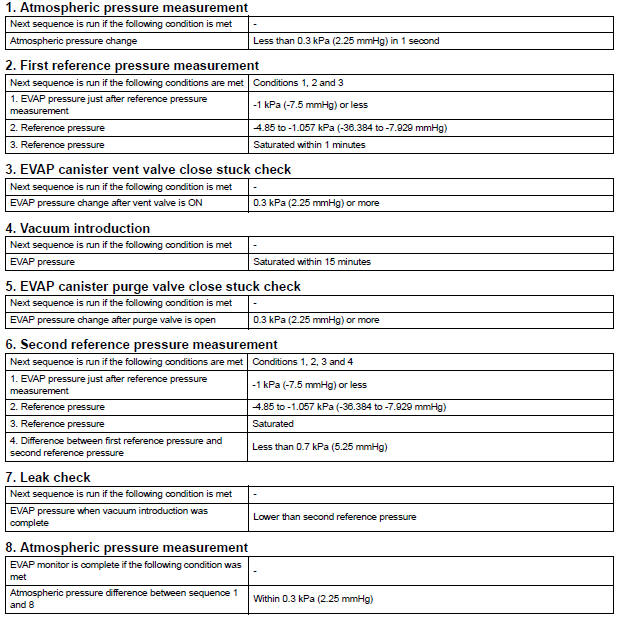

5 hours*1 after the ignition switch is turned off, the electric vacuum pump creates negative pressure (vacuum) in the EVAP (Evaporative Emission) system. The ECM monitors for leaks and actuator malfunctions based on the EVAP pressure.

HINT:

*1: If the engine coolant temperature is not below 35┬░C (95┬░F) 5 hours after the ignition switch is turned off, the monitor check starts 2 hours later. If it is still not below 35┬░C (95┬░F) 7 hours after the ignition switch is turned off, the monitor check starts 2.5 hours later.

*2: If only a small amount of fuel is in the fuel tank, it takes longer for the EVAP pressure to stabilize.

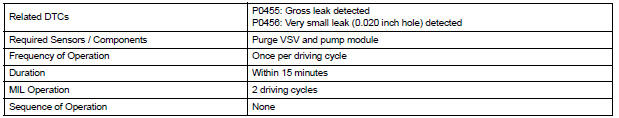

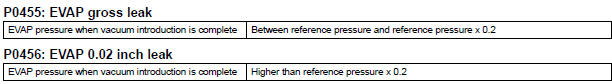

1. P0455: EVAP (Evaporative Emission) gross leak

In operation C, the vacuum pump creates negative pressure (vacuum) in the EVAP system and the EVAP system pressure is measured. If the stabilized system pressure is higher than [second 0.02 inch leak pressure standard x 0.2] (near atmospheric pressure), the ECM determines that the EVAP system has a large leak, illuminates the MIL and sets the DTC (2 trip detection logic).

2. P0456: EVAP very small leak

In operation C, the vacuum pump creates negative pressure (vacuum) in the EVAP system and the EVAP system pressure is measured. If the stabilized system pressure is higher than second 0.02 inch leak pressure standard, the ECM determines that the EVAP system has a small leak, illuminates the MIL and sets the DTC (2 trip detection logic).

MONITOR STRATEGY

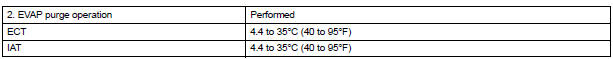

TYPICAL ENABLING CONDITIONS

Key-off monitor sequence 1 to 8

TYPICAL MALFUNCTION THRESHOLDS

MONITOR RESULT

Refer to CHECKING MONITOR STATUS (See page ES-19).

Evaporative Emission Control System Incorrect Purge Flow

Evaporative Emission Control System Incorrect Purge Flow

DTC SUMMARY

DESCRIPTION

The circuit description can be found in the EVAP (Evaporative Emission)

System (See page ES-409).

INSPECTION PROCEDURE

Refer to the EVAP System (See page ES-412).

MO ...

Vehicle Speed Sensor "A"

Vehicle Speed Sensor "A"

DESCRIPTION

The speed sensor detects the wheel speed and sends the appropriate signals to

the skid control ECU.

The skid control ECU converts these wheel speed signals into a 4-pulse signal ...

Other materials:

Removal

1. PRECAUTION

CAUTION:

Be sure to read "PRECAUTION" thoroughly before

servicing.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait for 90 seconds after disconnecting the cable to

prevent the airbag working.

3. PLACE FRONT WHEELS FACING STRAIGHT AHEAD

4. REMOVE STEE ...

Speedometer Malfunction

DESCRIPTION

Factors that affect the indicated vehicle speed include tire size, tire

inflation, and tire wear. The speed indicated on the speedometer has an

allowable margin of error. This can be tested using a speedometer tester

(calibrated chassis dynamometer). For details about testing and ...

Insufficient Coolant Temperature for Closed Loop Fuel Control

DESCRIPTION

Refer to DTC P0115 (See page ES-133).

MONITOR DESCRIPTION

The resistance of the ECT sensor varies in proportion to the actual ECT. The

ECM supplies a constant

voltage to the sensor and monitors the signal output voltage of the sensor. The

signal voltage output

varies acc ...