Toyota Sienna Service Manual: Evaporative Emission System Switching Valve Control Circuit High

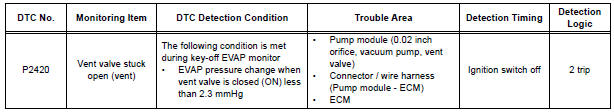

DTC P2420 Evaporative Emission System Switching Valve Control Circuit High

DTC SUMMARY

DESCRIPTION

The circuit description can be found in the EVAP (Evaporative Emission) System.

INSPECTION PROCEDURE

Refer to the EVAP System.

MONITOR DESCRIPTION

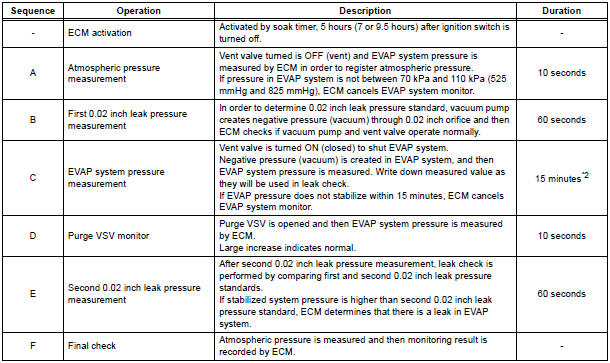

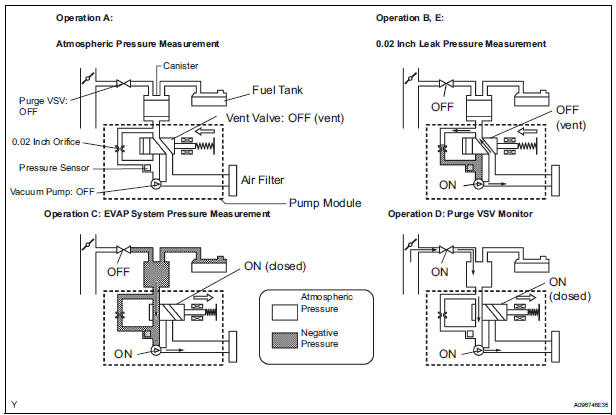

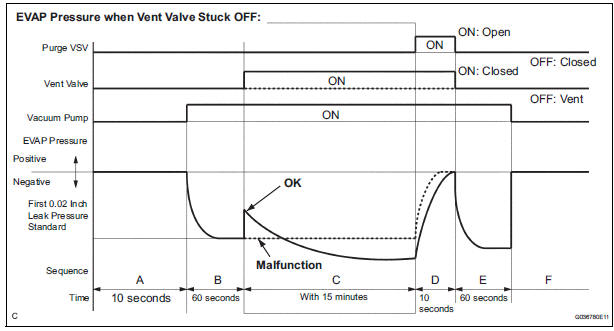

5 hours*1 after the ignition switch is turned off, the electric vacuum pump creates negative pressure (vacuum) in the EVAP (Evaporative Emission) system. The ECM monitors for leaks and actuator malfunctions based on the EVAP pressure.

HINT: *1: If the engine coolant temperature is not below 35C (95F) 5 hours after the ignition switch is turned off, the monitor check starts 2 hours later. If it is still not below 35C (95F) 7 hours after the ignition switch is turned off, the monitor check starts 2.5 hours later.

*2: If only a small amount of fuel is in the fuel tank, it takes longer for the EVAP pressure to stabilize.

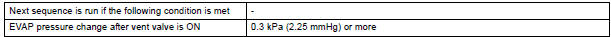

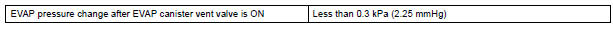

The vent valve turns ON (closes) and the EVAP (Evaporative Emission) system pressure is then measured by the ECM, using the pressure sensor, to conduct an EVAP leak check. If the pressure does not increase when the vent valve is open, the ECM interprets this as the vent valve being stuck open. The ECM illuminates the MIL and sets the DTC.

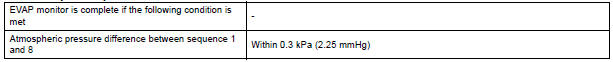

MONITOR STRATEGY

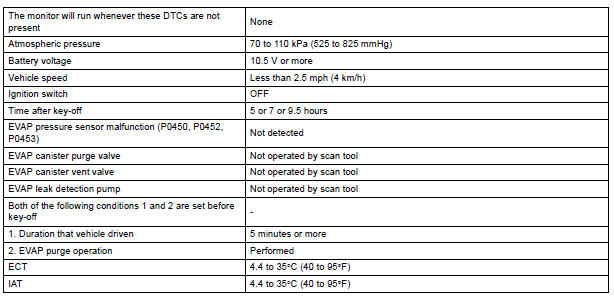

TYPICAL ENABLING CONDITIONS

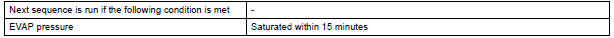

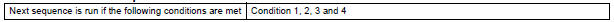

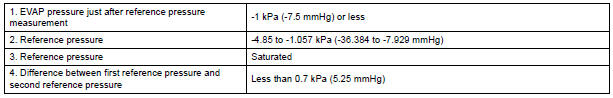

Key-off monitor sequence 1 to 8

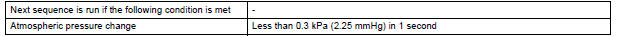

1. Atmospheric pressure measurement

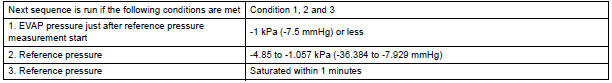

2. First reference pressure measurement

3. EVAP canister vent valve close stuck check

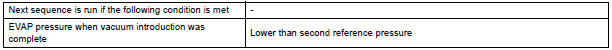

4. Vacuum introduction

5. EVAP canister purge valve close stuck check

6. Second reference pressure measurement

7. Leak check

8. Atmospheric pressure measurement

TYPICAL MALFUNCTION THRESHOLDS

MONITOR RESULT

Refer to CHECKING MONITOR STATUS

Oxygen (A/F) Sensor Pumping Current Circuit

Oxygen (A/F) Sensor Pumping Current Circuit

DTC P2238 Oxygen (A/F) Sensor Pumping Current Circuit

Low (Bank 1 Sensor 1)

DTC P2239 Oxygen (A/F) Sensor Pumping Current Circuit

High (Bank 1 Sensor 1)

DTC P2241 Oxygen (A/F) Sensor Pumping Curre ...

ECM / PCM Internal Engine Off Timer Performance

ECM / PCM Internal Engine Off Timer Performance

DTC P2610 ECM / PCM Internal Engine Off Timer Performance

DTC SUMMARY

DESCRIPTION

To ensure the accuracy of the EVAP (Evaporative Emission) monitor values, the

soak timer, which is built

int ...

Other materials:

Removal

HINT:

Use the same procedures for the RH side and LH side.

The procedures listed below are for the LH side.

1. PRECAUTION

CAUTION: Be sure to read "PRECAUTION" thoroughly before

servicing.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait for 90 s ...

Diagnosis system

1. CHECK DLC3

The vehicle's ECU uses ISO 15765-4 for

communication protocol. The terminal arrangement

of the DLC3 complies with SAE J1962 and matches

the ISO 15765-4 format.

NOTICE:

*: Before measuring the resistance, leave the

vehicle as is for at least 1 minute and do not

ope ...

Heater relay (for rear air conditioning system)

ON-VEHICLE INSPECTION

1. INSPECT REAR HEATER RELAY

(a) Remove the rear heater relay.

(b) Measure the resistance according to the value(s) in

the table below.

Standard resistance

If the resistance is not as specified, replace the rear

heater relay. ...