Toyota Sienna Service Manual: Fuel Pump Control Circuit

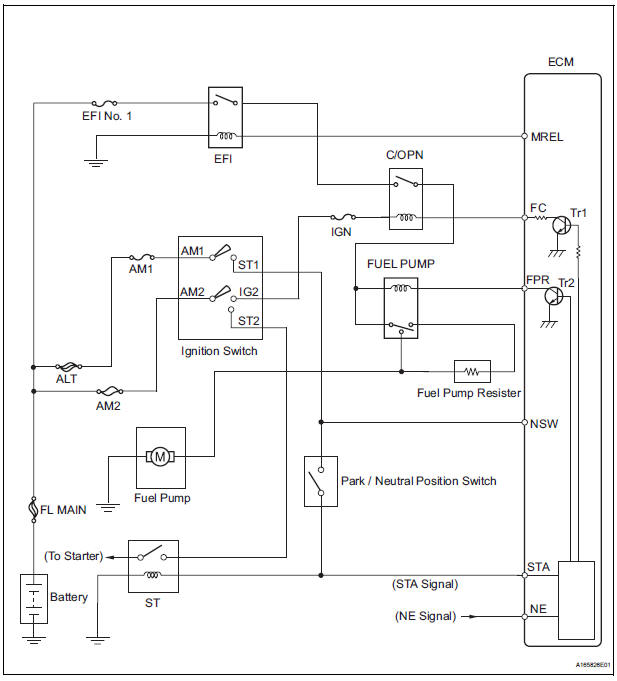

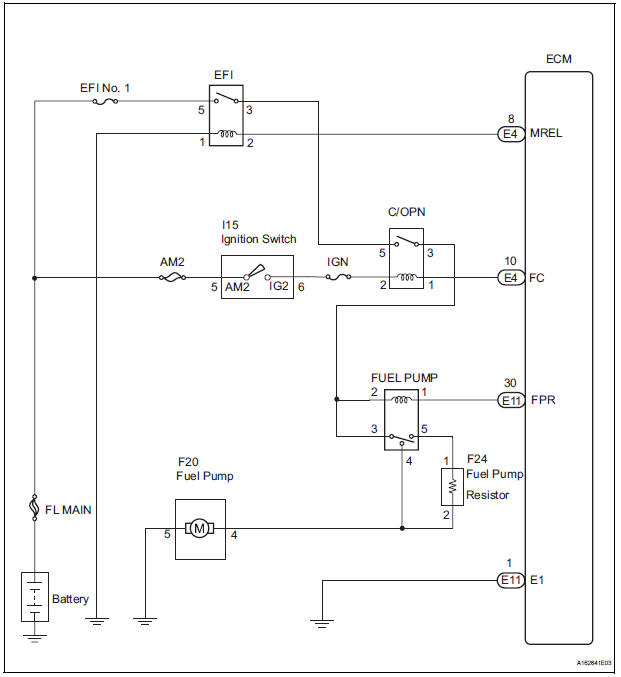

DESCRIPTION

The FUEL PUMP relay switches the fuel pump speed according to the engine conditions. The fuel pump operates when the ECM receives the starter-operating signal (STA) and crankshaft-rotating signal (NE).

The FUEL PUMP relay is turned ON while the engine is idling or operating at low load. This causes current to flow through the fuel pump resistor to the fuel pump. The fuel pump then operates at low speed.

The FUEL PUMP relay is turned OFF while the engine is cranking or operating at high load. The fuel pump then operates at normal speed.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK FUEL PUMP

(a) Check if there is pressure in the fuel inlet hose.

HINT:

If there is fuel pressure, the sound of fuel flowing will be heard.

2 PERFORM ACTIVE TEST BY INTELLIGENT TESTER (OPERATE C/OPN RELAY)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the intelligent tester or the OBD II scan tool main switch on.

(c) Enter the following menus: DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST / FUEL PUMP / SPD.

(d) Check the relay operation while operating it using the intelligent tester.

Standard: Operating noise can be heard from the relay.

3 INSPECT RELAY (C/OPN RELAY)

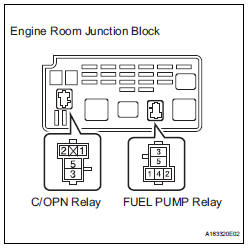

(a) Remove the C/OPN relay from the engine room junction block.

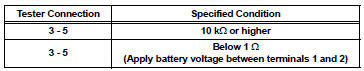

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

(c) Reinstall the C/OPN relay.

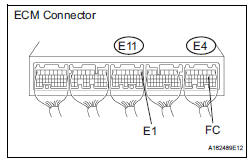

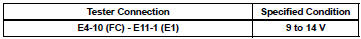

4 INSPECT ECM (FC VOLTAGE)

(a) Turn the ignition switch to the ON position.

(b) Measure the voltage according to the value(s) in the table below.

Standard voltage

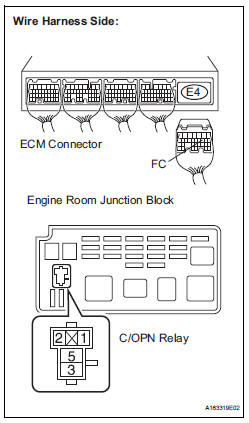

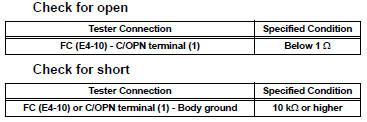

5 CHECK HARNESS AND CONNECTOR (ECM - C/OPN RELAY)

(a) Disconnect the E4 ECM connector.

(b) Remove the C/OPN relay from the engine room junction block.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance:

(d) Reconnect the ECM connector.

(e) Reinstall the C/OPN relay.

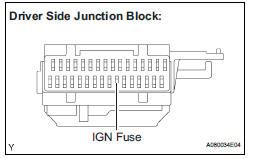

6 CHECK FUSE (IGN FUSE)

(a) Remove the IGN fuse from the driver side junction block.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance: Below 1 Ω

(c) Reinstall the IGN fuse.

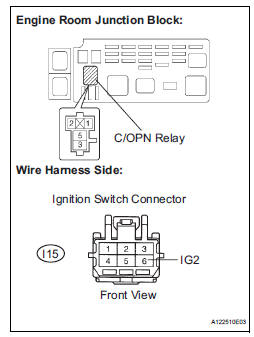

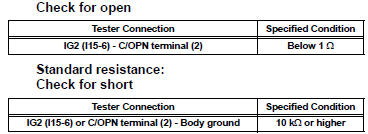

7 CHECK HARNESS AND CONNECTOR (C/OPN RELAY - IGNITION SWITCH)

a) Reconnect the I15 ignition switch connector.

(b) Remove the C/OPN relay from the engine room junction block.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance:

(d) Reconnect the ignition switch connector.

(e) Reinstall the C/OPN relay.

8 CHECK ECM POWER SOURCE CIRCUIT

9 INSPECT RELAY (FUEL PUMP RELAY)

(a) Remove the fuel pump relay from the engine room junction block.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

(c) Reinstall the fuel pump relay.

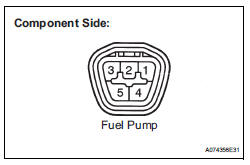

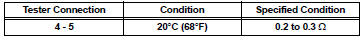

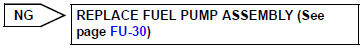

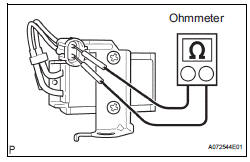

10 INSPECT FUEL PUMP

(a) Measure the resistance of the fuel pump.

(1) Measure the resistance according to the value(s) in the table below.

Standard resistance

(b) Check operation of the fuel pump.

(1) Apply battery voltage to both terminals. Check that the pump operates.

NOTICE:

|

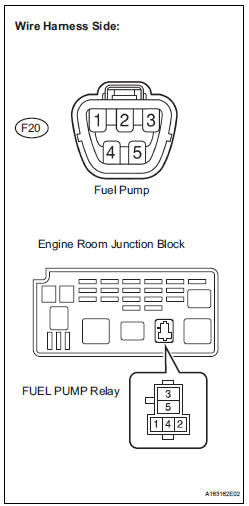

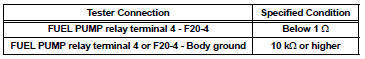

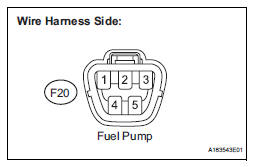

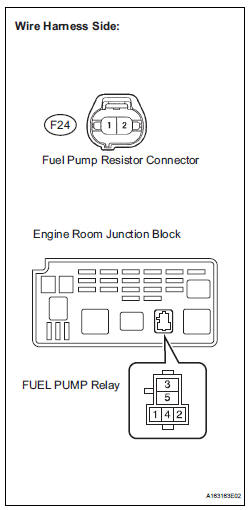

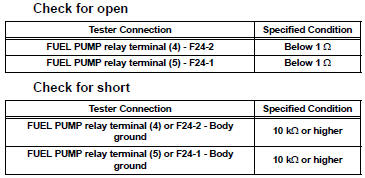

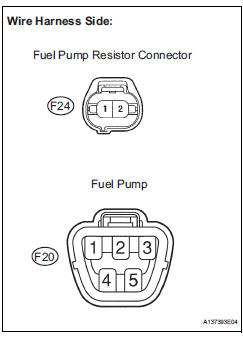

11 CHECK HARNESS AND CONNECTOR (FUEL PUMP - FUEL PUMP RELAY)

(a) Check the wire harness between the FUEL PUMP relay and fuel pump.

(1) Remove the FUEL PUMP relay from the engine room junction block.

(2) Disconnect the F20 fuel pump connector.

(3) Measure the resistance according to the value(s) in the table below.

Standard resistance

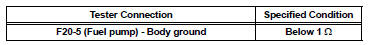

12 CHECK HARNESS AND CONNECTOR (FUEL PUMP - BODY GROUND)

(a) Check the wire harness between the fuel pump and body ground.

(1) Disconnect the F20 fuel pump connector.

(2) Measure the resistance between the terminal of the wire harness side connector and body ground.

Standard resistance

(b) Reinstall the FUEL PUMP relay.

(c) Reconnect the fuel pump connector.

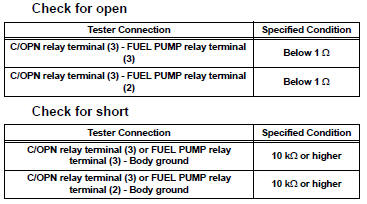

13 CHECK HARNESS AND CONNECTOR (C/OPN RELAY - FUEL PUMP RELAY)

(a) Remove the C/OPN relay from the engine room junction block.

(b) Remove the FUEL PUMP relay from the engine room junction block.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance:

(d) Reinstall the C/OPN relay.

(e) Reinstall the FUEL PUMP relay.

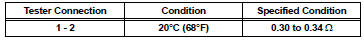

14 INSPECT FUEL PUMP RESISTOR

(a) Disconnect the F24 fuel pump resistor connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

(c) Reconnect the fuel pump resistor connector.

15 CHECK HARNESS AND CONNECTOR (FUEL PUMP RELAY - FUEL PUMP RESISTOR)

(a) Disconnect the F24 fuel pump resistor connector.

(b) Remove the FUEL PUMP relay from the engine room junction block.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance:

(d) Reconnect the fuel pump resistor connector.

(e) Reinstall the FUEL PUMP relay.

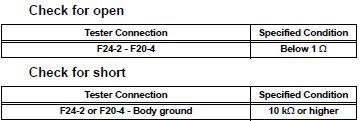

16 CHECK HARNESS AND CONNECTOR (FUEL PUMP RESISTOR - FUEL PUMP)

(a) Disconnect the F24 fuel pump resistor connector.

(b) Disconnect the F20 fuel pump connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance:

(d) Reconnect the fuel pump resistor connector.

(e) Reconnect the fuel pump connector.

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE (See page ES-27)

VC Output Circuit

VC Output Circuit

DESCRIPTION

The ECM constantly uses 5 V from the battery voltages supplied to the +B

(BATT) terminal to operate the

microprocessor. The ECM also provides this power to the sensors through the VC

...

Cranking Holding Function Circuit

Cranking Holding Function Circuit

DESCRIPTION

The system detects the ignition switch's starting signal (STSW) and then

supplies current to the starter

until the ECM judges that the engine has started successfully. The purpose is t ...

Other materials:

Initialization

1. RESET

When the back door lock is replaced:

The power back door ECU cannot receive a switch

signal from the lock. This may cause the power

back door system to enter fail-safe mode and DTC

B2215 to set, and also make the system disabled.

When the lock is replaced, be sure to perform t ...

Brake fluid

Checking fluid level

The brake fluid level should be

between the “MAX” and “MIN”

lines on the tank.

“MAX” line

“MIN” line

Adding fluid

Lift the cover off.

Make sure to check the fluid type and prepare the necessary item.

Brake fluid can absorb moisture from t ...

Eject Error/ Elevator Error/ Clamp Error

DTC 63-45 Eject Error

DTC 63-51 Elevator Error

DTC 63-52 Clamp Error

DESCRIPTION

DTC No.

DTC Detection Condition

Trouble Area

63-45

Magazine cannot be ejected.

Radio and navigation assembly

63-51

Mechanical error occurs during elevator ...