Toyota Sienna Service Manual: VC Output Circuit

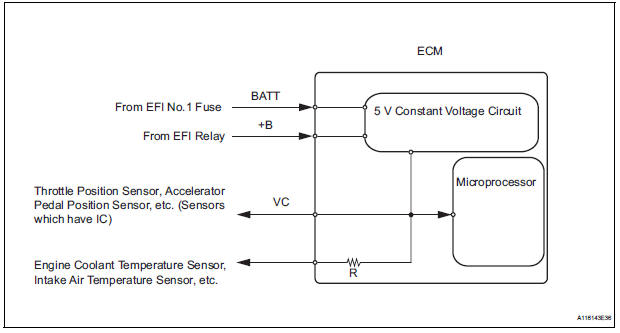

DESCRIPTION

The ECM constantly uses 5 V from the battery voltages supplied to the +B (BATT) terminal to operate the microprocessor. The ECM also provides this power to the sensors through the VC output circuit.

When the VC circuit is short-circuited, the microprocessor in the ECM and sensors that are supplied power through the VC circuit are inactivated because the power is not supplied from the VC circuit. Under this condition, the system does not start up and the MIL does not illuminate even if the system malfunctions.

HINT:

Under normal conditions, the MIL is illuminated for several seconds when the ignition switch is first turned to the ON position. The MIL goes off when the engine is started.

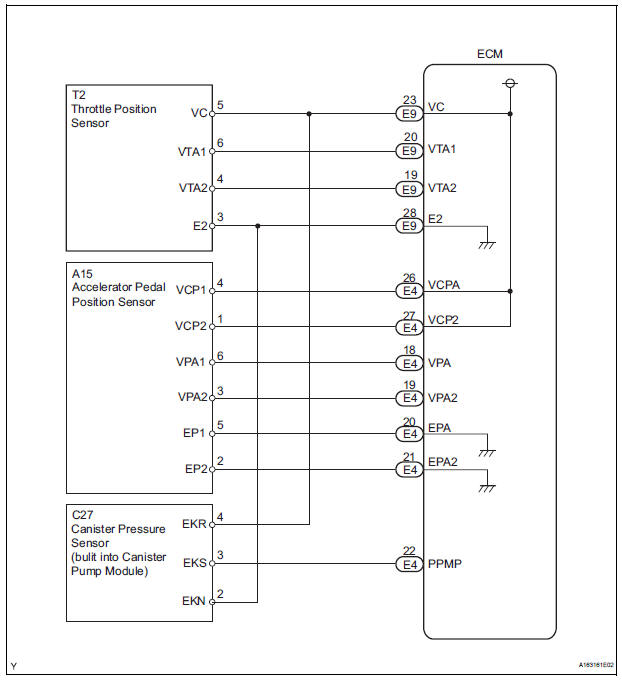

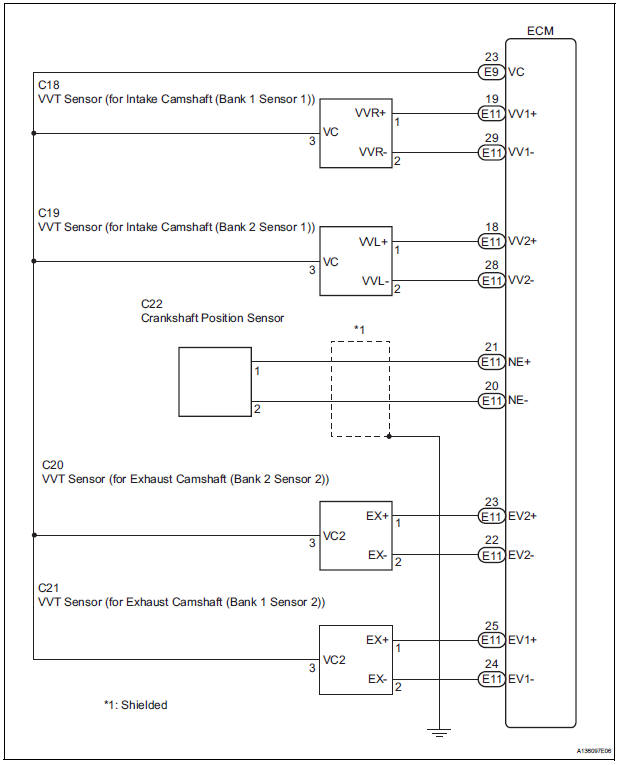

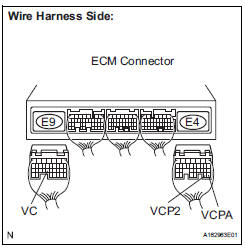

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK MIL

(a) Check that the Malfunction Indicator Lamp (MIL) lights up when turning the ignition switch to the ON position.

OK: MIL lights up.

2 CHECK CONNECTION BETWEEN INTELLIGENT TESTER AND ECM

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the tester on.

(c) Check the communication between the tester and ECM.

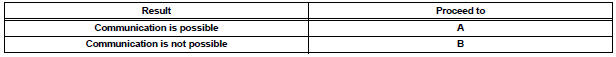

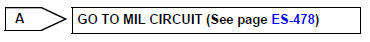

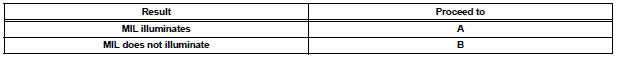

Result

3 CHECK THROTTLE BODY (CHECK MIL ILLUMINATED)

(a) Disconnect the throttle body connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

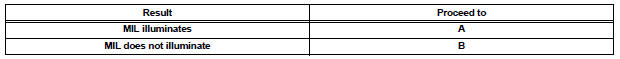

Result

(d) Reconnect the throttle body connector.

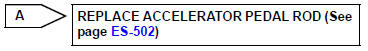

4 CHECK ACCELERATOR PEDAL ROD (CHECK MIL ILLUMINATED)

(a) Disconnect the accelerator pedal position sensor connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

Result

(d) Reconnect the accelerator pedal position sensor connector.

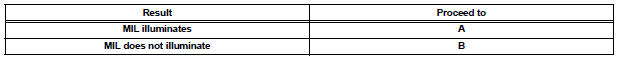

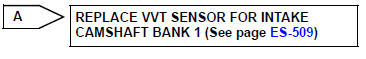

5 CHECK VVT SENSOR FOR INTAKE CAMSHAFT BANK 1 (CHECK MIL ILLUMINATED)

(a) Disconnect the VVT sensor for intake camshaft bank 1 connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

Result

(d) Reconnect the VVT sensor for intake camshaft bank 1 connector.

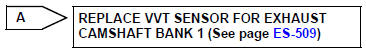

6 CHECK VVT SENSOR FOR EXHAUST CAMSHAFT BANK 1 (CHECK MIL ILLUMINATED)

(a) Disconnect the VVT sensor for exhaust camshaft bank 1 connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

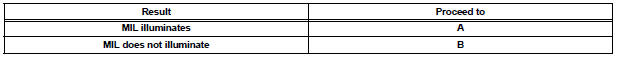

Result

(d) Reconnect the VVT sensor for exhaust camshaft bank 1 connector.

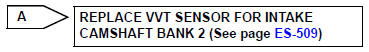

7 CHECK VVT SENSOR FOR INTAKE CAMSHAFT BANK 2 (CHECK MIL ILLUMINATED)

(a) Disconnect the VVT sensor for intake camshaft bank 2 connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

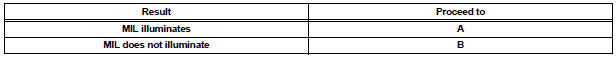

Result

(d) Reconnect the VVT sensor for intake camshaft bank 2 connector.

8 CHECK VVT SENSOR FOR EXHAUST CAMSHAFT BANK 2 (CHECK MIL ILLUMINATED)

(a) Disconnect the VVT sensor for exhaust camshaft bank 2 connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

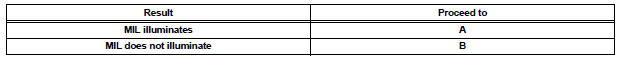

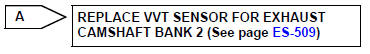

Result

(d) Reconnect the VVT sensor for exhaust camshaft bank 2 connector.

9 CHECK CHARCOAL CANISTER ASSEMBLY (CHECK MIL ILLUMINATED)

(a) Disconnect the canister pump module connector.

(b) Turn the ignition switch to the ON position.

(c) Check the MIL.

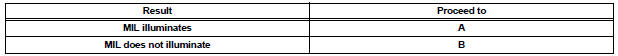

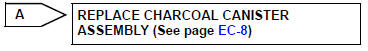

Result

(d) Reconnect the canister pump module connector.

10 CHECK HARNESS AND CONNECTOR

(a) Disconnect the throttle body connector.

(b) Disconnect the accelerator pedal position sensor connector.

(c) Disconnect the VVT sensor for intake camshaft bank 1 connector.

(d) Disconnect the VVT sensor for exhaust camshaft bank 1 connector.

(e) Disconnect the VVT sensor for intake camshaft bank 2 connector.

(f) Disconnect the VVT sensor for exhaust camshaft bank 2 connector.

(g) Disconnect the canister pump module connector.

(h) Disconnect the E9 and E4 ECM connectors.

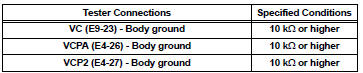

(i) Measure the resistance according to the value(s) in the table below.

Standard resistance (Check for short)

(j) Reconnect the ECM connectors.

(k) Reconnect the canister pump module connector.

(l) Reconnect the VVT sensor for exhaust camshaft bank 2 connector.

(m) Reconnect the VVT sensor for intake camshaft bank 2 connector.

(n) Reconnect the VVT sensor for exhaust camshaft bank 1 connector.

(o) Reconnect the VVT sensor for intake camshaft bank 1 connector.

(p) Reconnect the accelerator pedal position sensor connector.

(q) Reconnect the throttle body connector.

REPLACE ECM (See page ES-498)

ECM Power Source Circuit

ECM Power Source Circuit

DESCRIPTION

When the ignition switch is turned to the ON position, the battery voltage is

applied to terminal IGSW of

the ECM. The ECM MREL output signal causes a current to flow to the coil,

cl ...

Fuel Pump Control Circuit

Fuel Pump Control Circuit

DESCRIPTION

The FUEL PUMP relay switches the fuel pump speed according to the engine

conditions. The fuel pump

operates when the ECM receives the starter-operating signal (STA) and

crankshaft-ro ...

Other materials:

Radio Broadcast cannot be Received or Poor Reception

INSPECTION PROCEDURE

1 CHECK RADIO RECEIVER

Check the radio's automatic station search function.

Check the radio's automatic station search function

by activating it.

OK:

The radio's automatic station search function

works properly.

2 CONFIRM MODEL

Result

3 INSPECT RADIO ...

Calling the message sender

Calls can be made to an e-mail/SMS/MMS message senderãs phone

number.

Display the message inbox screen.

Select the desired message.

Select .

Check that the ãCallã screen is displayed.

Calling from a number within a message

Calls can be made to a number identified in a messageã ...

Vehicle Speed Sensor "A"

DESCRIPTION

The speed sensor detects the wheel speed and sends the appropriate signals to

the skid control ECU.

The skid control ECU converts these wheel speed signals into a 4-pulse signal

and outputs it to the ECM

via the combination meter. The ECM determines the vehicle speed based o ...