Toyota Sienna Service Manual: How to proceed with troubleshooting

HINT:

The intelligent tester can be used in steps 2, 3, 4, 6 and 9.

1 VEHICLE BROUGHT TO WORKSHOP

2 CONNECT INTELLIGENT TESTER TO DLC3

HINT:

If the display indicates a communication fault in the tester, inspect the DLC3.

3 CHECK DTC AND FREEZE FRAME DATA

(a) Check for DTC(s) and freeze frame data (See page ES- 40).

HINT:

Record or print the DTCs and freeze frame data, if necessary.

4 CLEAR DTC AND FREEZE FRAME DATA

(a) Clear the DTC(s) and freeze frame data (See page ES- 40).

5 CONDUCT VISUAL INSPECTION

6 SET CHECK MODE DIAGNOSIS

(a) Set the check mode (See page ES-43).

7 CONFIRM PROBLEM SYMPTOMS

HINT:

If the engine does not start, perform steps 9 and 11 first.

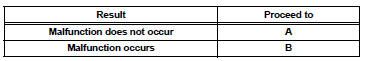

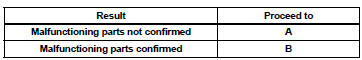

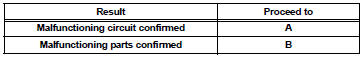

Result

8 SIMULATE SYMPTOMS

9 CHECK FOR DTCS

(a) Check for DTCs (See page ES-39).

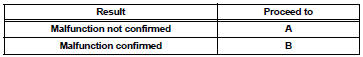

Result

10 REFER TO DTC CHART

HINT:

Refer to the DTC chart (See page ES-56).

| GO TO STEP 13 |

11 CONDUCT BASIC INSPECTION

HINT:

Refer to "BASIC INSPECTION" (See page ES-13).

Result

12 REFER TO PROBLEM SYMPTOMS TABLE

HINT:

Refer to "PROBLEM SYMPTOMS TABLE" (See page ES- 27).

Result

13 CHECK ECM POWER SOURCE CIRCUIT

HINT:

Refer to "ECM POWER SOURCE CIRCUIT" (See page ES- 437).

14 CONDUCT CIRCUIT INSPECTION

Result

15 CHECK FOR INTERMITTENT PROBLEMS

HINT:

Refer to "CHECK FOR INTERMITTENT PROBLEMS" (See page ES-13).

| GO TO STEP 17 |

16 CONDUCT PARTS INSPECTION

17 IDENTIFY PROBLEM

18 ADJUST AND/OR REPAIR

19 CONDUCT CONFIRMATION TEST

END

System diagram

System diagram

...

Check for intermittent problems

Check for intermittent problems

1. CHECK FOR INTERMITTENT PROBLEMS

HINT:

For use of the intelligent tester only:

Inspect the vehicle's ECM using check mode.

Intermittent problems are easier to detect with an

intelligent teste ...

Other materials:

Open in Front Pretensioner Squib RH Circuit

DTC B0131/64 Open in Front Pretensioner Squib RH Circuit

DESCRIPTION

The front pretensioner squib RH circuit consists of the center airbag sensor

assembly and the front seat

outer belt assembly RH.

This circuit instructs the SRS to deploy when deployment conditions are met.

DTC B0131/64 i ...

Installation

1. INSTALL REAR NO. 2 SEAT ASSEMBLY LH

Place the rear No. 2 seat assembly LH in the cabin.

NOTICE:

Be careful not to damage the body.

Install the rear No. 2 seat assembly LH with the 2

bolts.

Torque: 29 N*m (296 kgf*cm, 21 ft.*lbf)

Install the locus cable with the ...

Rear washer motor

ON-VEHICLE INSPECTION

1. INSPECT REAR WASHER MOTOR

Pour the water into the washer jar with the rear

washer motor assembly installed to the washer jar

assembly.

Connect the battery (+) to the terminal 1 of the rear

washer motor assembly, the battery (-) to the

terminal ...