Toyota Sienna Service Manual: Indicator Circuit

DESCRIPTION

The indicator displays the location of the obstacle and the approximate distance between the vehicle and the obstacle either by blinking or turning on.

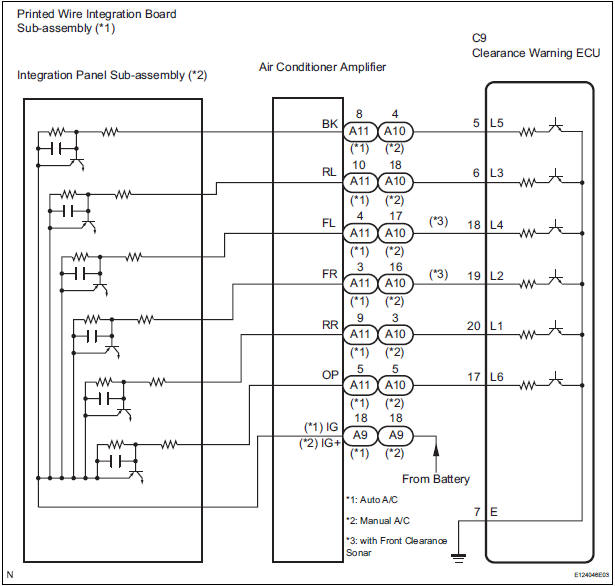

WIRING DIAGRAM

INSPECTION PROCEDURE

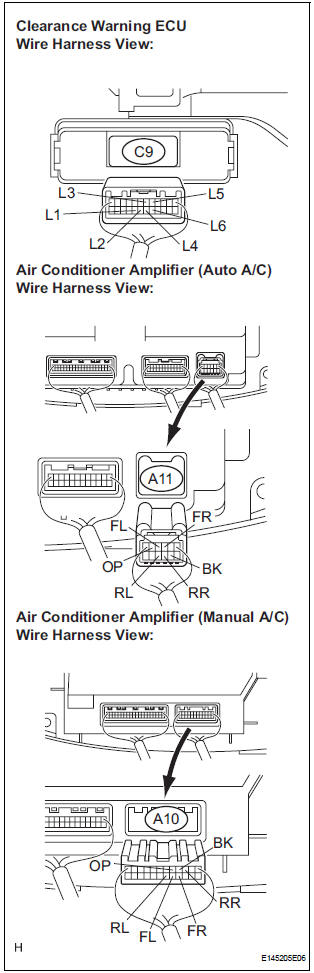

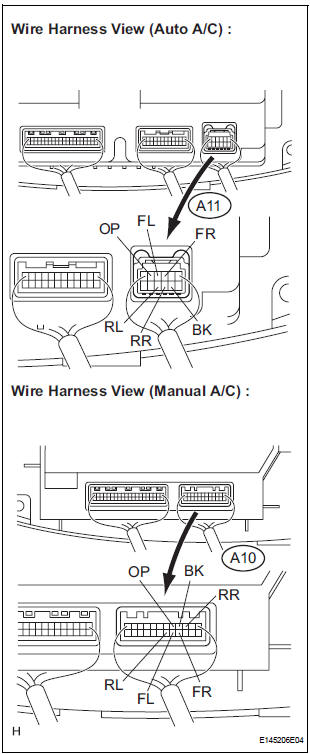

1 CHECK HARNESS AND CONNECTOR (CLEARANCE WARNING ECU - AIR CONDITIONER AMPLIFIER)

- Disconnect the connectors from the clearance warning ECU C9 and air conditioner amplifier connector A10 or A11.

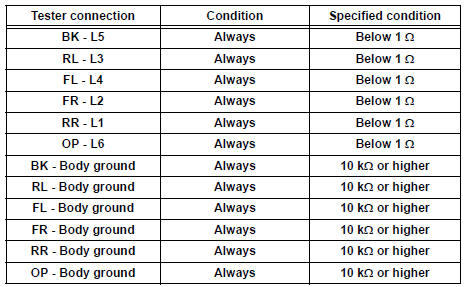

- Measure the resistance according to the value(s) in the table below.

Standard resistance

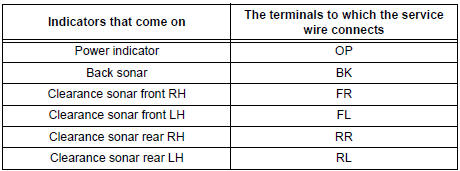

2 INSPECT INDICATOR

- Remove the integration control & panel assembly with the connectors being connected.

- Using a service wire, ground each terminal of the integration control & panel assembly connector.

- Turn the ignition switch ON.

- Check that each LED comes on.

Result

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

3 INSPECT PRINTED WIRE INTEGRATION BOARD SUB-ASSEMBLY

- Check the malfunction disappears when a known good printed wire integration board sub-assembly is installed

OK: Malfunction disappears.

REPLACE PRINTED WIRE INTEGRATION BOARD SUB-ASSEMBLY

4 INSPECT INTEGRATION PANEL SUB-ASSEMBLY

- Check that the malfunction disappears when a known good integration panel sub-assembly is installed.

OK: Malfunction disappears

REPLACE INTEGRATION PANEL SUB-ASSEMBLY

No. 2 Clearance Warning Buzzer Circuit

No. 2 Clearance Warning Buzzer Circuit

DESCRIPTION

The clearance warning ECU receives the ultrasonic sensor signal to sound the

rear warning buzzer.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK HARNESS AND CONNECTOR (CLEARANCE WAR ...

Horn

Horn

...

Other materials:

On-vehicle inspection

1. INSPECT MASS AIR FLOW METE

NOTICE:

Perform the mass air flow (MAF) meter inspection

by following the procedures below.

Only replace the MAF meter when the MAF value

in the DATA LIST (with the engine stopped) are

not within the normal operating range or there is

fore ...

How to proceed with

troubleshooting

1 VEHICLE BROUGHT TO WORKSHOP

2 CUSTOMER PROBLEM ANALYSIS

3 CHECK AND CLEAR DTCs

Refer to the diagnostic check/clear

4 PROBLEM SYMPTOM CONFIRMATION

5 SYMPTOM SIMULATION

6 CHECK DTC

7 CHECK IF THE SAME SYMPTOM APPEARS IN THE NAVIGATION SYSTEM

Refer to the navigation system

8 PROBLE ...

Removal

1. REMOVE CHARCOAL CANISTER PROTECTOR

(a) Remove the 6 bolts and charcoal canister protector.

2. REMOVE CHARCOAL CANISTER ASSEMBLY

(a) Disconnect the fuel tank vent hose from the

charcoal canister.

(1) Push the connector deep inside.

(2) Pinch portion A.

(3) Pull out the connector.

...