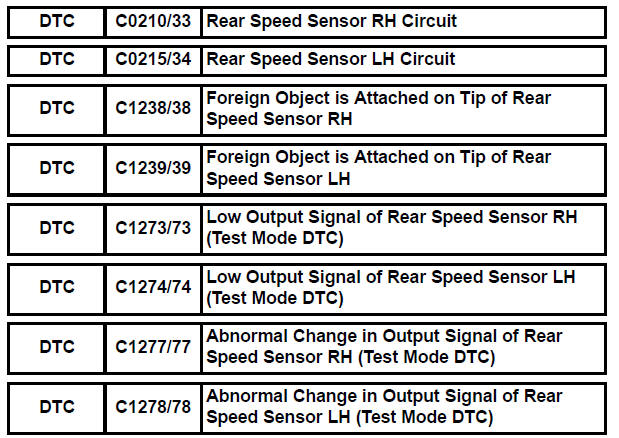

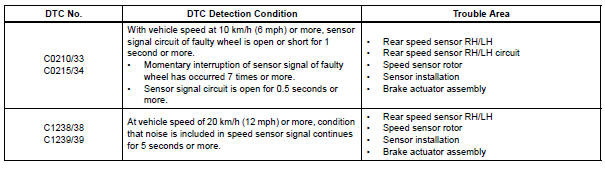

Toyota Sienna Service Manual: Rear Speed Sensor RH Circuit

DESCRIPTION

Refer to DTCs C0200/31, C0205/32, C1235/35, and C1236/36 (See page BC-17).

DTCs C1273/73 to C1278/78 can be deleted when the speed sensor sends a vehicle speed signal or the Test Mode ends. DTCs C1273/73 to C1278/78 are output only in the Test Mode.

HINT:

- DTC C0210/33 and C1238/38 are for the rear speed sensor RH.

- DTC C0215/34 and C1239/39 are for the rear speed sensor LH.

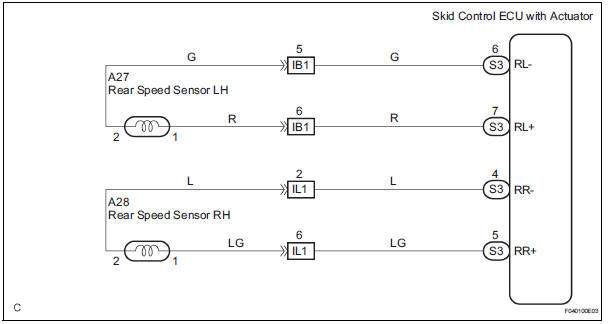

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT: Start the inspection from step 1 when using the intelligent tester and start from step 3 when not using the intelligent tester.

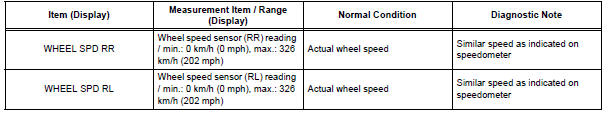

1 READ VALUE OF INTELLIGENT TESTER (REAR SPEED SENSOR)

(a) Select the DATA LIST mode on the intelligent tester.

ABS:

(b) Check that there is the speed value output from the speed sensor displayed on the intelligent tester and the speed value displayed on the speedometer are almost the same when driving the vehicle.

OK: The speed value output from the speed sensor displayed on the intelligent tester is the same as the actual vehicle speed.

2 PERFORM TEST MODE INSPECTION (SIGNAL CHECK)

(a) Clear the DTC (See page BC-10).

(b) Perform sensor signal check in TEST MODE PROCEDURE (See page BC-3).

OK: All Test Mode DTCs are erased.

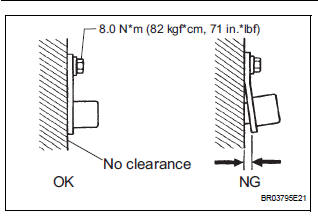

3 INSPECT REAR SPEED SENSOR INSTALLATION

(a) Turn the ignition switch off.

(b) Check the speed sensor installation.

OK: The installation nut is tightened properly.

There is no clearance between the sensor and the rear axle.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

NOTICE: Check the speed sensor signal after replacement (See page BC-3).

4 INSPECT SPEED SENSOR TIP

(a) Remove the rear speed sensor (See page BC-190).

(b) Check the sensor tip.

OK: No scratches or foreign matter on the sensor tip.

NOTICE: Check the speed sensor signal after cleaning or replacement (See page BC-3).

5 INSPECT HARNESS AND CONNECTOR (BETWEEN REAR SPEED SENSOR AND SKID CONTROL SENSOR WIRE)

(a) Install the rear speed sensor.

(b) Disconnect the rear speed sensor connector.

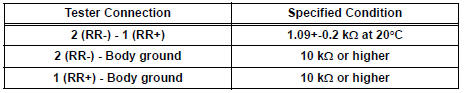

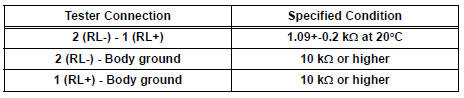

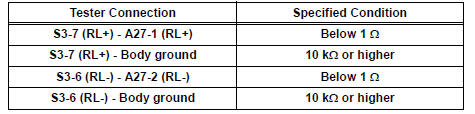

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance

RH:

LH:

NOTICE: Check the speed sensor signal after replacement (See page BC-3).

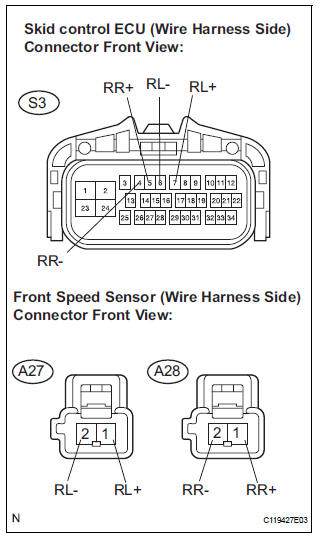

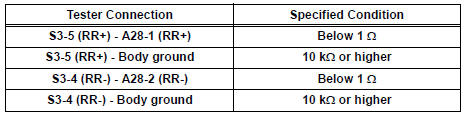

6 CHECK HARNESS AND CONNECTOR (BETWEEN SKID CONTROL ECU AND REAR SPEED SENSOR)

(a) Disconnect the skid control ECU connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

RH:

LH:

7 INSPECT SPEED SENSOR AND SENSOR ROTOR SERRATIONS

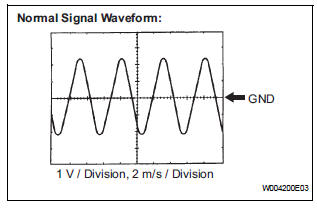

(a) Connect the oscilloscope to terminals FR+ - FR- or FL+ - FL- of the skid control ECU.

(b) Drive the vehicle at about 30 km/h (19 mph), and check the signal waveform.

OK: A waveform as shown in the figure should be output.

HINT:

- As vehicle speed (wheel rotation speed) increases, the width of the waveform narrows and the fluctuation in the output voltage becomes greater.

- When noise is identified in the waveform on the oscilloscope, error signals are generated due to rotor scratches, looseness or foreign matter attached to the speed sensor.

8 RECONFIRM DTC

(a) Clear the DTCs (See page BC-10).

(b) Drive the vehicle at a speed of approximately 32 km/h (20 mph) or more for 60 seconds or more.

(c) Check that the same DTCs are recorded (See page BC- 10).

HINT: Reinstall the sensors, connectors, etc. and restore the vehicle to its prior condition before rechecking for DTCs.

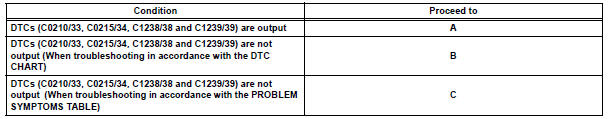

Result

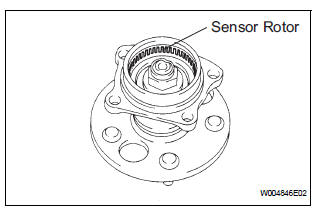

9 INSPECT SPEED SENSOR ROTOR

(a) Turn the ignition switch off.

(b) Remove the rear axle hub and bearing (See page AH- 16).

(c) Check the rotor.

OK: No scratches, oil, or foreign matter on the rotors.

NOTICE: Check the speed sensor signal after cleaning or replacement (See page BC-3).

REPLACE BRAKE ACTUATOR ASSEMBLY

Front Speed Sensor RH Circuit

Front Speed Sensor RH Circuit

DESCRIPTION

The speed sensor detects wheel speed and transmits the appropriate signals to

the ECU. These signals

are used for control of the ABS control system. The front and rear rotors have ...

SFR Solenoid Circuit

SFR Solenoid Circuit

DESCRIPTION

The solenoid comes on when signals are received from the ECU and controls the

pressure acting on the

wheel cylinders, thus controlling brake force.

WIRING DIAGRAM

INSPECT ...

Other materials:

Master Cylinder Pressure Sensor Malfunction

DTC C1246/46 Master Cylinder Pressure Sensor Malfunction

DESCRIPTION

Master cylinder pressure sensor is connected to the skid control ECU in the

actuator.

INSPECTION PROCEDURE

1 READ VALUE ON INTELLIGENT TESTER (MASTER CYLINDER PRESSURE SENSOR)

(a) Connect the intelligent tester to the DL ...

Receiving a call

When a call is received, the following screen is displayed

together with a sound.

To answer the phone

Press the switch on the steering

wheel or select .

To refuse a call

Press the switch on the steering

wheel or select

To adjust the incoming call volume

Turn the ÔÇťPWRÔÇóVOLÔÇŁ knob ...

Power seat switch

Inspection

1. INSPECT FRONT POWER SEAT SWITCH

Inspect the driver side power seat switch.

Measure the resistance according to the

value(s) in the table below.

Standard resistance:

Slide switch

Front vertical switch

Lifter switch

Reclining switch

If the res ...