Toyota Sienna Service Manual: Removal

1. DISCHARGE FUEL SYSTEM PRESSURE HINT: See page FU-1.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

3. REMOVE NO. 1 ENGINE UNDER COVER

4. DRAIN ENGINE COOLANT (See page CO-6)

5. REMOVE FRONT WIPER ARM HEAD CAP (See page WW-4)

6. REMOVE FRONT WIPER ARM RH (See page WW-4)

7. REMOVE FRONT WIPER ARM LH (See page WW-4)

8. REMOVE COWL TOP VENTILATOR LOUVER SUBASSEMBLY (See page WW-4)

9. REMOVE WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY (See page WW-4)

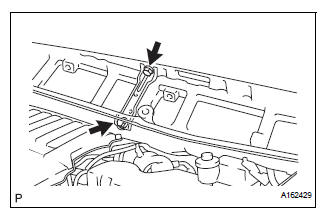

10. REMOVE NO. 1 COWL TOP TO COWL BRACE INNER

(a) Remove the 2 bolts and the No. 1 cowl top to cowl brace inner.

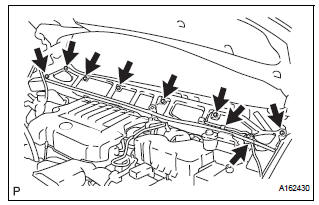

11. REMOVE COWL TOP PANEL SUB-ASSEMBLY OUTER FRONT

(a) Remove the wire harness clamp.

(b) Disconnect the fuel pump resistor connector.

(c) Remove the 7 bolts and the cowl top panel outer front.

12. REMOVE V-BANK COVER SUB-ASSEMBLY (See page EM-28)

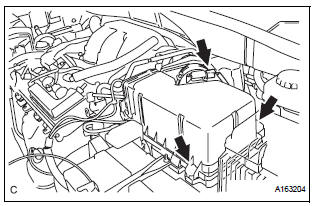

13. REMOVE AIR CLEANER CAP SUB-ASSEMBLY

(a) Disconnect the 3 vacuum hoses.

(b) Remove the No. 2 ventilation hose and air cleaner hose band.

(c) Disconnect the vacuum hose (EVAP) from the air cleaner hose.

(d) Remove the 2 bolts and air cleaner cap subassembly.

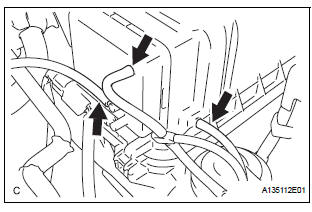

14. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

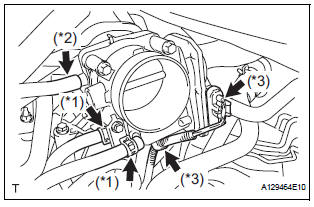

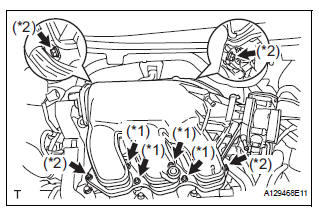

(a) Disconnect the 2 water by-pass hoses from the throttle with motor body assembly. (*1) (b) Disconnect the fuel vapor feed hose assembly.(*2) (c) Disconnect the throttle with motor body assembly connector and clamp. (*3)

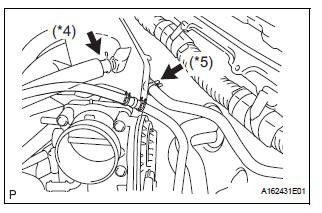

(d) Disconnect the No. 1 ventilation hose. (*4) (e) Disconnect the union to check valve hose. (*5)

(f) Disconnect the connector.

(g) Using a 5 mm socket hexagon wrench, remove the 4 bolts. (*1) (h) Remove the 2 nuts, 2 bolts, and intake air surge tank. (*2) (i) Remove the gasket from the intake air surge tank.

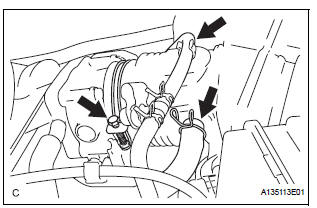

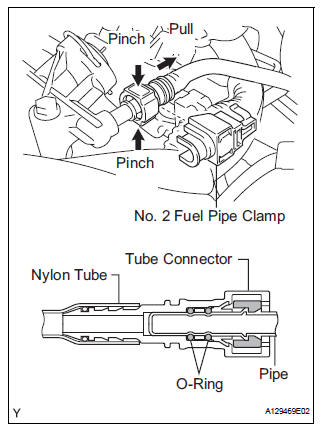

15. DISCONNECT FUEL TUBE SUB-ASSEMBLY

(a) Remove the No. 2 fuel pipe clamp.

(b) Pinch the tube connector and pull out the fuel pipe.

NOTICE:

|

16. REMOVE FUEL INJECTOR ASSEMBLY

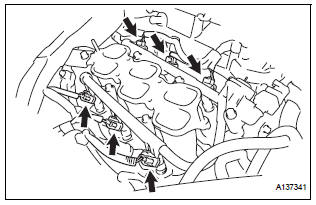

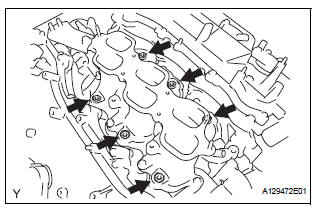

(a) Disconnect the 6 fuel injector connectors.

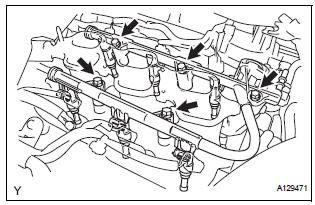

(b) Remove the 5 bolts and fuel delivery pipe subassembly together with the 6 fuel injectors.

| NOTICE: Be careful not to drop the fuel injectors when removing the fuel delivery pipe sub-assembly. |

(c) Remove the 6 injector vibration insulators from the intake manifold.

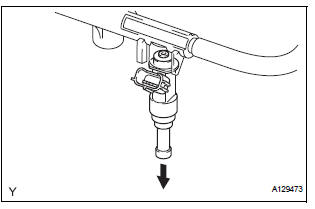

(d) Pull out the fuel injectors from the fuel delivery pipe sub-assembly

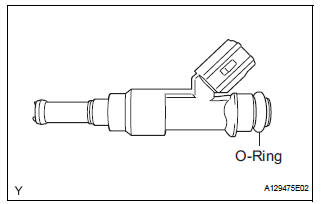

(e) Remove the 6 O-rings from the fuel injectors.

Components

Components

...

Inspection

Inspection

1. INSPECT FUEL INJECTOR ASSEMBLYV

(A) inspect the injector resistance.

(1) Using an ohmmeter, measure the resistance

between the terminals.

Standard resistance

If the resistance is not a ...

Other materials:

Crankshaft Position Sensor

DESCRIPTION

The Crankshaft Position (CKP) sensor system consists of a CKP sensor plate

and a pickup coil. The

sensor plate has 34 teeth and is installed on the crankshaft. The pickup coil is

made of an iron core and a

magnet.

The sensor plate rotates as each tooth passes through the pi ...

Terminals of ECU

1. POSITION CONTROL ECU AND SWITCH ASSEMBLY

(POWER SEAT CONTROL SWITCH AND ECU)

Disconnect the P58 and P59 connectors.

Check the voltage of each terminal of the wire

harness side connectors.

If the result is not as specified, there may be a

malfunction in the wire harn ...

Memory Switch Circuit

DESCRIPTION

When the seat memory switch M1 or M2 is pressed, the position control ECU &

switch (Seat ECU)

transmits a signal of the memorized mirror position to the outer mirror control

ECU. Then, the outer mirror

control ECU drives the mirror motor.

HINT:

The power mirror control syste ...