Toyota Sienna Service Manual: Inspection

1. INSPECT PARK/NEUTRAL POSITION SWITCH ASSEMBLY OPERATION

(a) Apply the parking brake and turn the ignition switch to the ON position.

(b) Depress the brake pedal and check that the engine starts only when the shift lever is in the N or P position and the engine does not start when the shift lever is in other positions.

(c) Check that the back up light comes on and the reverse warning buzzer sounds only when the shift lever is in the R position and the light and buzzer do not operate when the shift lever is in other positions.

(d) If a failure is found, check the park/neutral position switch for continuity.

2. INSPECT PARK/NEUTRAL POSITION SWITCH ASSEMBLY

(a) Jack up the vehicle.

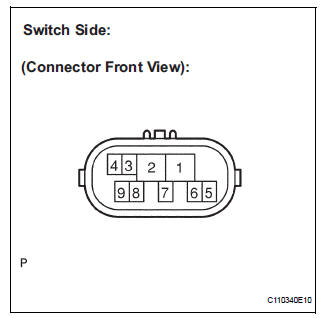

(b) Disconnect the park/neutral position switch connector.

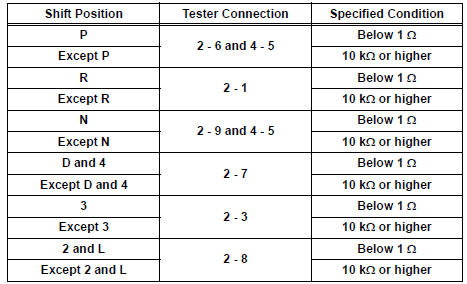

(c) Measure the resistance according to the value(s) in the table below when the shift lever is moved to each position.

Resistance

ADJUSTMENT

1. ADJUST PARK/NEUTRAL POSITION SWITCH ASSEMBLY

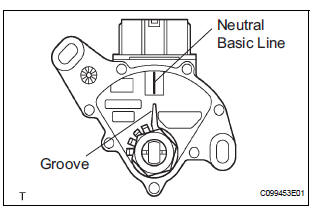

(a) Loosen the 2 bolts of the park/neutral position switch and move the shift lever to the N position.

(b) Align the groove with the neutral basic line.

(c) Hold the switch in position and tighten the 2 bolts.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf) (d) After adjustment, perform the inspection described in park/neutral position switch assembly operation.

Removal

Removal

1. REMOVE BATTERY

2. REMOVE AIR CLEANER ASSEMBLY

HINT:

(See page EM-26)

3. SEPARATE TRANSMISSION CONTROL CABLE ASSEMBLY

(a) Remove the nut from the control shaft lever.

(b) Disconnect the ...

Installation

Installation

1. INSTALL PARK/NEUTRAL POSITION SWITCH ASSEMBLY

(a) Install the park/neutral position switch to the manual

valve shaft.

(b) Temporarily install the 2 bolts.

(c) Place a new lock plate a ...

Other materials:

Registration

HINT:

Register the recognition code when replacing the door

control transmitter or the door control receiver.

Add mode is used to register new recognition codes while

still retaining codes already registered. This mode is used

when a new transmitter is added. If the number of ...

Disassembly

HINT:

On the RH side, use the same procedures as on the LH side.

1. REMOVE FRONT DOOR LOWER FRAME BRACKET GARNISH LH

Using a screwdriver, disengage the clip and claw,

and remove the garnish.

HINT:

Tape the screwdriver tip before use.

2. REMOVE FRONT DOOR INSIDE HANDLE BEZEL PLUG LH

...

For front passenger side

ON-VEHICLE INSPECTION

1. INSPECT AIR MIX CONTROL SERVO MOTOR

(a) Remove the air mix control servo motor.

(b) Connect the positive (+) lead from the battery to

terminal 4 and negative (-) lead to terminal 5, then

check that the lever turns to "COOL" side smoothly.

(c) Connect ...