Toyota Sienna Service Manual: On-vehicle inspection

1. INSPECT THROTTLE BODY

(a) Listen to the throttle control motor operating sounds.

(1) Turn the ignition switch to the ON position.

(2) When pressing the accelerator pedal position sensor lever, listen to the running motor. Make sure that no friction noise comes from the motor.

If friction noise exists, replace the throttle body.

(b) Inspect the throttle position sensor.

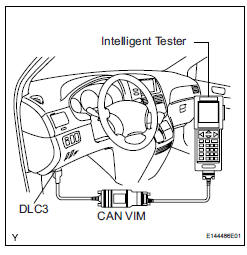

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Check that the MIL turns off.

(4) Under CURRENT DATA, the throttle valve opening percentage (THROTTLE POS) should be within the standard range below.

Standard throttle valve opening percentage: 60% or more If the percentage is less than 60%, replace the throttle body.

| NOTICE: When checking the throttle valve opening percentage, the transmission should be in neutral. |

Throttle body

Throttle body

COMPONENTS

...

Removal

Removal

1. Remove windshield wiper motor assembly

hint:

(see page ww-4)

2. Remove front outer cowl top panel subassembly

(see page em-27)

3. Drain engine coolant (see page co-6)

4. Remove v-bank cover s ...

Other materials:

Installation

1. INSTALL FRONT DRIVE SHAFT ASSEMBLY LH

(a) Coat the spline of the inboard joint shaft assembly

with ATF.

(b) Align the shaft splines and install the drive shaft

assembly with a brass bar and hammer.

NOTICE:

Set the snap ring with the opening side facing

down.

Be careful not to d ...

Cranking Holding Function Circuit

DESCRIPTION

The system detects the ignition switch's starting signal (STSW) and then

supplies current to the starter

until the ECM judges that the engine has started successfully. The purpose is to

reduce the holding time

of the ignition key.

WIRING DIAGRAM

Refer to DTC P0617 (See page ...

PBD Pulse Sensor Malfunction

DTC B2222 PBD Pulse Sensor Malfunction

DESCRIPTION

A pulse sensor is built into the back door for a jam and foreign

object detection and for back door

position detection. The jam and foreign object detection feature of the

pulse sensor monitors the

operating speed of the back door whi ...