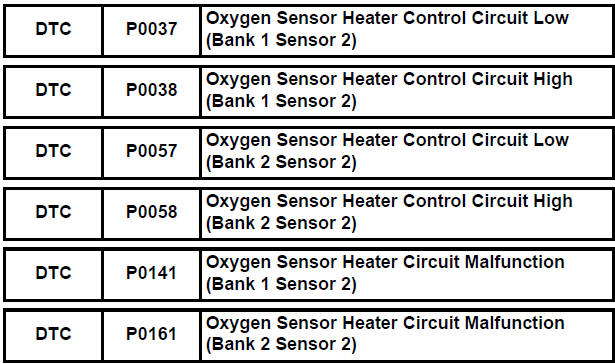

Toyota Sienna Service Manual: Oxygen Sensor Heater Control Circuit

HINT:

Sensor 2 refers to the sensor mounted behind the Three-Way Catalytic Converter (TWC) and located furthest from the engine assembly.

DESCRIPTION

Refer to DTC P0136 (See page ES-160).

HINT:

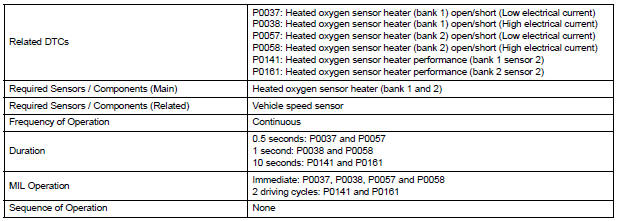

When any of these DTCs are set, the ECM enters fail-safe mode. The ECM turns off the Heated Oxygen (HO2) sensor heater in fail-safe mode. Fail-safe mode continues until the ignition switch is turned off.

HINT:

- Bank 1 refers to the bank that includes cylinder No. 1.

- Bank 2 refers to the bank that does not include cylinder No. 1.

- Sensor 1 refers to the sensor closest to the engine assembly

- Sensor 2 refers to the sensor furthest away from the engine assembly.

MONITOR DESCRIPTION

The sensing position of the Heated Oxygen (HO2) sensor has a zirconia element which is used to detect the oxygen concentration in the exhaust gas. If the zirconia element is at the appropriate temperature, and the difference between the oxygen concentrations surrounding the inside and outside surfaces of the sensor is large, the zirconia element generates voltage signals. In order to increase the oxygen concentration detecting capacity of the zirconia element, the ECM supplements the heat from the exhaust with heat from a heating element inside the sensor.

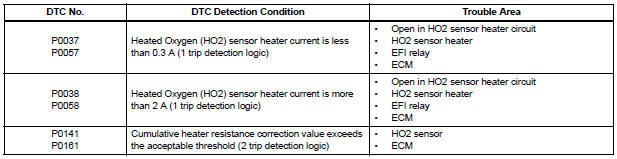

Heated oxygen sensor heater range check (P0037, P0038, P0057 and P0058): The ECM monitors the current applied to the O2 sensor heater to check the heater for malfunctions. If the current is below the threshold value, the ECM will determine that there is an open circuit in the heater. If the current is above the threshold value, the ECM will determine that there is a short circuit in the heater.

Example: The ECM sets DTC P0038 or P0058 when the current in the HO2 sensor heater is more than 2 A.

Conversely, when the heater current is less than 0.3 A, DTC P0037 or P0057 is set.

Heated oxygen sensor heater performance (P0141 and P0161): After the accumulated heater ON time exceeds 100 seconds, the ECM calculates the heater resistance using the battery voltage and the current applied to the heater. If the resistance is above the threshold value, the ECM will determine that there is a malfunction in the HO2S heater and set DTC P0141 and P0161.

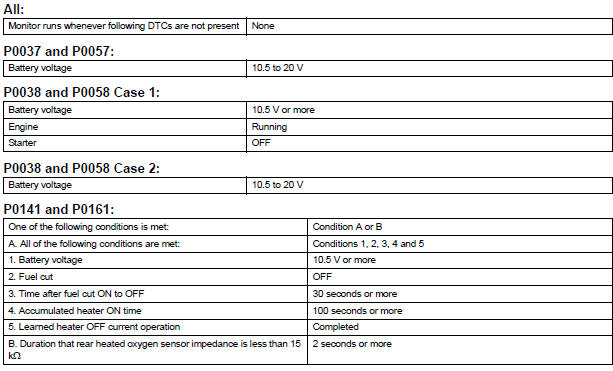

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

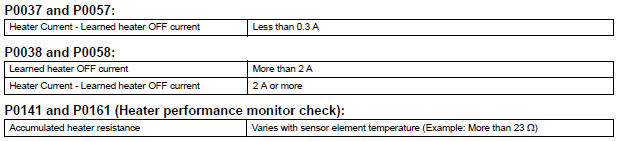

TYPICAL MALFUNCTION THRESHOLDS

COMPONENT OPERATING RANGE

MONITOR RESULT

Refer to CHECKING MONITOR STATUS (See page ES-19).

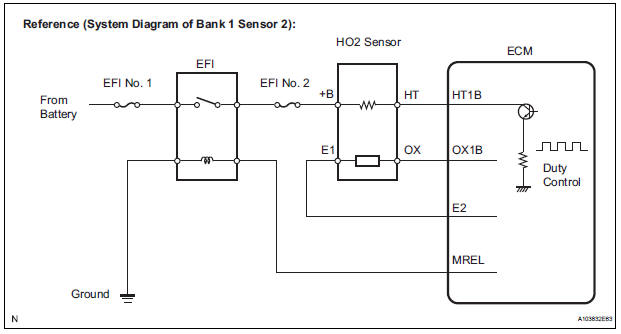

WIRING DIAGRAM

Refer to DTC P0136 (See page ES-167).

INSPECTION PROCEDURE

HINT:

- If other DTCs relating to different systems that have terminal E2 as the ground terminal are output simultaneously, terminal E2 may have an open circuit.

- Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

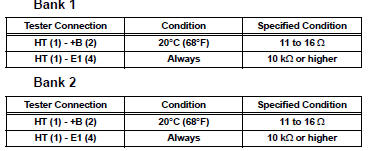

1 INSPECT HEATED OXYGEN SENSOR (HEATER RESISTANCE)

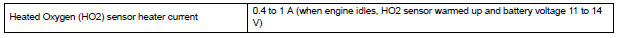

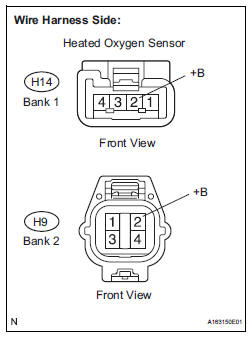

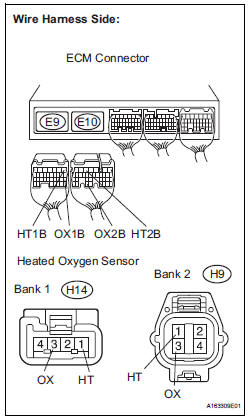

(a) Disconnect the H14 heated oxygen (HO2) sensor connector (Bank 1 Sensor 2) or H9 heated oxygen sensor connector (Bank 2 Sensor 2).

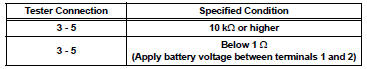

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance:

(c) Reconnect the HO2 sensor connectors.

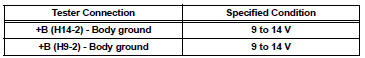

2 CHECK TERMINAL VOLTAGE (+B OF SENSOR)

(a) Disconnect the H14 or H9 HO2 sensor connector.

(b) Turn the ignition switch to the ON position.

(c) Measure the voltage according to the value(s) in the table below.

Standard voltage

(d) Reconnect the HO2 sensor connector.

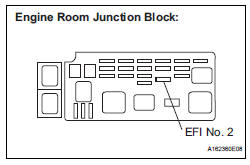

3 INSPECT FUSE (EFI NO. 2 FUSE)

(a) Remove the EFI No. 2 fuse from the engine room junction block.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance: Below 1 Ω

(c) Reinstall the EFI No. 2 fuse.

4 INSPECT RELAY (EFI RELAY)

(a) Remove the EFI relay from the engine room junction block.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

(c) Reinstall the EFI relay.

REPAIR OR REPLACE HARNESS OR CONNECTOR (HO2 SENSOR - EFI RELAY)

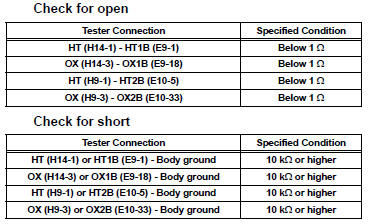

5 CHECK HARNESS AND CONNECTOR (HO2 SENSOR - ECM)

(a) Disconnect the H14 or H9 HO2 sensor connector.

(b) Disconnect the E9 and E10 ECM connectors.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance:

(d) Reconnect the ECM connectors.

(e) Reconnect the HO2 sensor connectors.

6 CHECK WHETHER DTC OUTPUT RECURS

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the intelligent tester ON.

(d) Clear the DTCs (See page ES-39).

(e) Start the engine.

(f) Allow the engine to idle for 1 minute or more.

(g) Select the following menu items: DIAGNOSIS / ENHANCED OBD II / DTC INFO / CURRENT CODES.

(h) Read the DTCs.

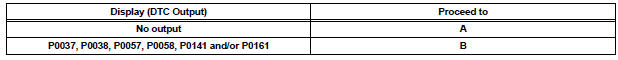

Result

CHECK FOR INTERMITTENT PROBLEMS

Oxygen (A/F) Sensor Heater Control Circuit

Oxygen (A/F) Sensor Heater Control Circuit

HINT

Although the DTC titles say the oxygen sensor, these DTCs relate to the

Air-Fuel Ratio (A/F) sensor.

Sensor 1 refers to the sensor mounted in front of the Three-Way

Catalytic Conv ...

Mass or Volume Air Flow Circuit

Mass or Volume Air Flow Circuit

DESCRIPTION

The Mass Air Flow (MAF) meter is a sensor that measures the amount of air

flowing through the throttle

valve. The ECM uses this information to determine the fuel injection time and ...

Other materials:

Air Intake Control Circuit

DESCRIPTION

The air cleaner is equipped with two inlets, one of which is opened or closed

by the Air Intake Control

Valve (AICV). This system reduces intake noise and increases engine power at

low-to-high engine speed

range.

When the engine is operating in the low-to-mid speed range, this ...

Ignition Switch Circuit

DESCRIPTION

When the ignition switch is turned to the ON position, battery positive

voltage is applied to terminal IG of

the ECU. When battery positive voltage is applied to terminal IG of the ECU

while the theft deterrent

system is operating, the warning stops.

WIRING DIAGRAM

INSPECTIO ...

Rear side sunshades

Rear door window

Rear quarter window

Pull the tab up.

Secure the sunshade using the hooks.

To retract the sunshade, pull the tab up slightly to unhook the sunshade,

and lower the sunshade slowly.

NOTICE

To ensure normal operation of the rear sunshades, observe ...