Toyota Sienna Service Manual: Air Intake Control Circuit

DESCRIPTION

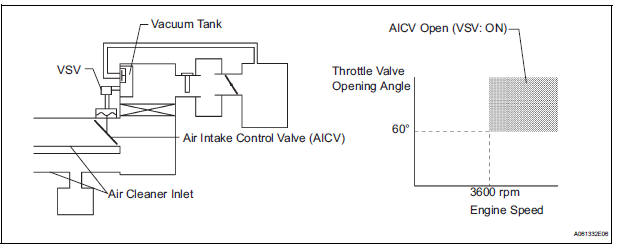

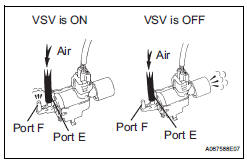

The air cleaner is equipped with two inlets, one of which is opened or closed by the Air Intake Control Valve (AICV). This system reduces intake noise and increases engine power at low-to-high engine speed range.

When the engine is operating in the low-to-mid speed range, this control operates the AICV to close one of the air cleaner inlets. When the engine speed is more than 3600 rpm and the opening angle of the throttle valve is more than 60°, the ECM activates the VSV and opens the AICV.

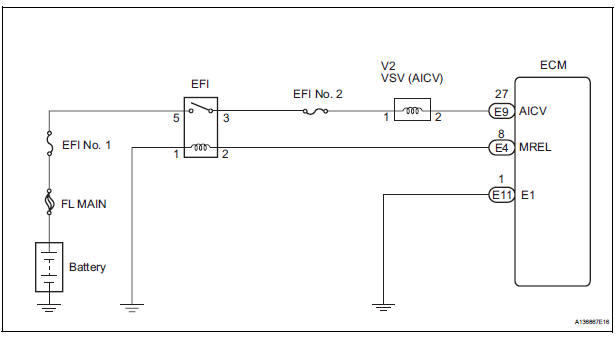

WIRING DIAGRAM

INSPECTION PROCEDURE

1 PERFORM ACTIVE TEST BY INTELLIGENT TESTER (VSV FOR AICV)

(a) Turn the ignition switch to the ON position and turn the intelligent tester on.

(b) Select the following menu items: DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST / INTAKE CTL VSV1 and operate the VSV for AICV.

(c) Check the operation of the VSV when the VSV is operated by the intelligent tester.

Standard

2 CHECK VSV (FOR AICV)

(a) Inspect the intake air control valve assembly (See page IT-8).

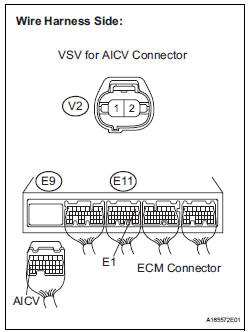

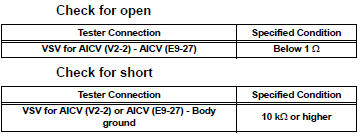

3 CHECK HARNESS AND CONNECTOR (VSV FOR AICV - ECM)

(a) Check the wire harness between the VSV for AICV connector and the ECM connector.

Standard resistance:

(4) Reconnect the ECM connector.

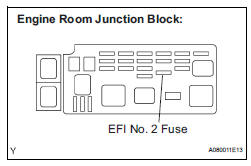

4 INSPECT FUSE (EFI NO. 2 FUSE)

(a) Check the EFI No. 2 fuse.

(1) Remove the EFI No. 2 fuse from the engine room junction block.

(2) Measure the EFI No. 2 fuse resistance.

Standard resistance: Below 1 Ω

(3) Reinstall the EFI No. 2 fuse.

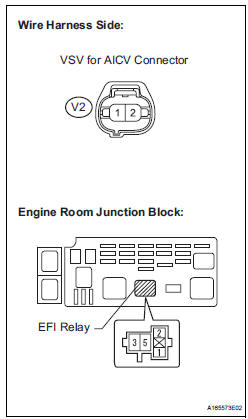

5 CHECK HARNESS AND CONNECTOR (VSV FOR AICV - EFI RELAY)

(a) Check the wire harness between the VSV for AICV and the EFI relay.

(1) Remove the EFI relay from the engine room junction block.

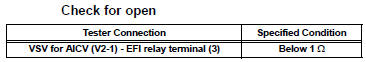

(2) Measure the resistance according to the value(s) in the table below

Standard resistance :

(3) Reconnect the VSV for AICV connector.

(4) Reinstall the EFI relay.

6 INSPECT VACUUM TANK

(a) Inspect the vacuum tank (See page IT-6).

CHECK ECM POWER SOURCE CIRCUIT

ACIS Control Circuit

ACIS Control Circuit

DESCRIPTION

This circuit opens and closes the Intake Air Control Valve (IACV) in response

to changes in the engine

load in order to increase the intake efficiency (ACIS: Acoustic Control

Inducti ...

MIL Circuit

MIL Circuit

DESCRIPTION

The MIL (Malfunction Indicator Lamp) is used to indicate vehicle malfunctions

detected by the ECM.

When the ignition switch is turned to the ON position, power is supplied to the

M ...

Other materials:

Receiving a message

When an e-mail/SMS/MMS is received, the incoming message screen

pops up with sound and is ready to be operated on the screen.

Select to check the message.

Select to refuse the message.

Select to call the message

sender.

Receiving a message

Depending on the cellular phone used f ...

Operation check

1. DETECTION RANGE MEASUREMENT AND INDICATOR CHECK

Turn the IG switch ON.

Move the shift lever to the R position (when the back

sonar and rear clearance sonar is checked).

With front clearance sonar:

Move the shift lever to the N position (when the front

clearance son ...

Disassembly

1. REMOVE FRONT DIFFERENTIAL RING GEAR

(a) Place matchmarks on the front differential ring gear

and differential case.

(b) Remove the 14 bolts.

(c) Using a plastic hammer, tap on the front differential

ring gear to remove it from the case.

2. REMOVE FRONT DIFFERENTIAL CASE FRONT TA ...