Toyota Sienna Service Manual: Park / Neutral Position Switch Circuit

DESCRIPTION

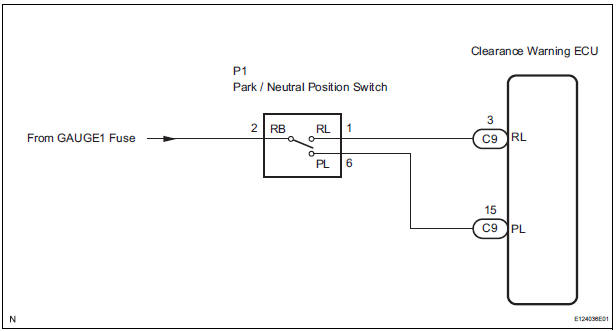

The clearance warning ECU receives the reverse or park position signal from the park / neutral position switch.

WIRING DIAGRAM

INSPECTION PROCEDURE

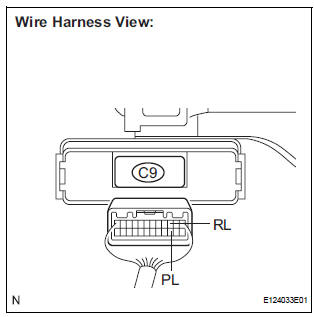

1 INSPECT CLEARANCE WARNING ECU

- Disconnect the C9 connector from the clearance warning ECU.

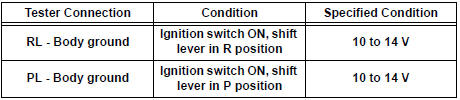

- Measure the voltage according to the value(s) in the table below.

Standard voltage

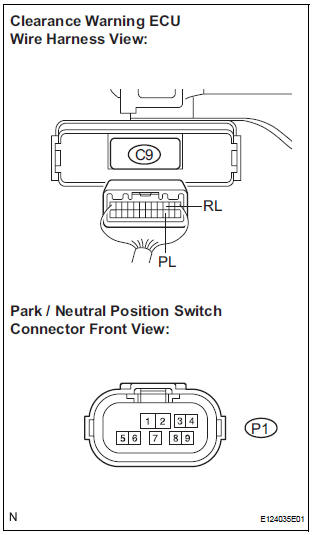

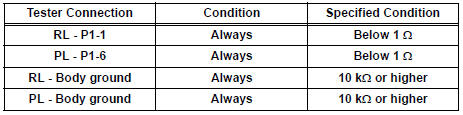

2 CHECK HARNESS AND CONNECTOR

- Disconnect the connector from the park / neutral position switch.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

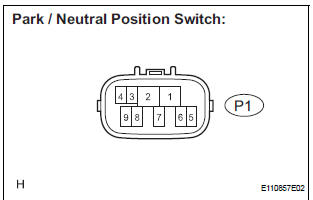

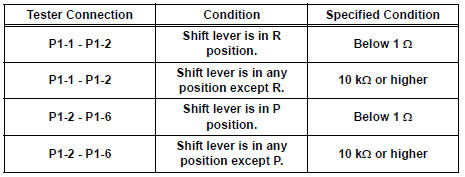

3 INSPECT PARK / NEUTRAL POSITION SWITCH

- Disconnect the park / neutral position switch connector P1.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

REPAIR OR REPLACE HARNESS OR CONNECTOR

Adjustment

Adjustment

1. ADJUST BUZZER VOLUME

Turn the knob on the clearance warning ECU to

adjust the volume.

...

Speed Signal Circuit

Speed Signal Circuit

DESCRIPTION

The clearance warning ECU receives the vehicle speed signal from the

combination meter.

HINT:

A voltage of 12 V or 5 V is output from each ECU and then input to

the combin ...

Other materials:

Installation

1. INSTALL ENGINE COOLANT TEMPERATURE SENSOR

Install the engine coolant temperature sensor.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf)

Connect the engine coolant temperature sensor

connector.

2. INSTALL AIR CLEANER CASE SUB-ASSEMBLY

3. INSTALL AIR CLEANER CAP SUB-ASSEMBLY

...

Glossary of tire terminology

Tire related term

Meaning

Cold tire inflation

pressure

Tire pressure when the vehicle has been

parked for three hours or more, or has not

been driven more than 1 mile or 1.5 km under

that condition

Maximum inflation

pressure

The maximum cold i ...

Installation

1. INSTALL STEERING PAD

Support the steering pad with one hand as shown in

the illustration.

Connect the 2 connectors to the steering pad.

NOTICE:

When handling the airbag connector, take care

not to damage the airbag wire harness.

Connect the horn connector.

...