Toyota Sienna Service Manual: Pressure Control Solenoid "C" Electrical (Shift Solenoid Valve SL3)

DESCRIPTION

Shifting from 1st to 5th is performed in combination with "ON" and "OFF"

operation of the shift solenoid

valves SL1, SL2, SL3, S4 and SR which are controlled by the ECM. If an open or

short circuit occurs in

either of the shift solenoid valves, the ECM controls the remaining normal shift

solenoid valves to allow

the vehicle to be operated smoothly (Fail safe function).

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". When there is an open or short circuit in any shift solenoid valve circuit, the ECM detects the problem and illuminates the MIL and stores the DTC. And the ECM performs the fail-safe function and turns the other normal shift solenoid valves "ON/OFF" (In case of an open or short circuit, the ECM stops sending current to the circuit.) (See page AX-30).

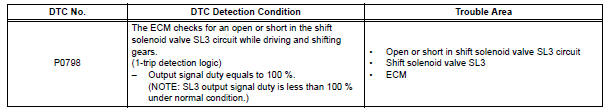

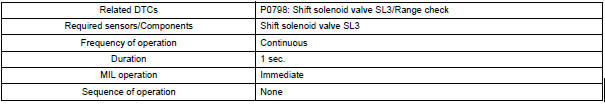

MONITOR STRATEGY

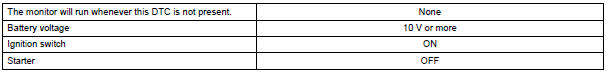

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

COMPONENT OPERATING RANGE

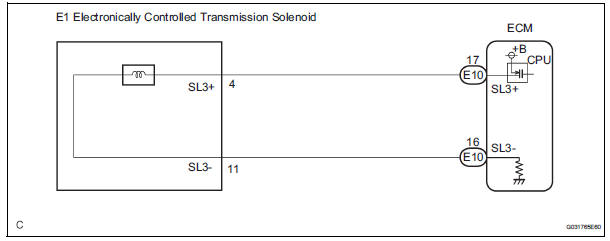

WIRING DIAGRAM

INSPECTION PROCEDURE

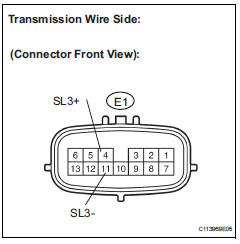

(a) Disconnect the transmission wire connector from the transaxle.

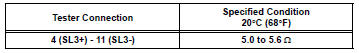

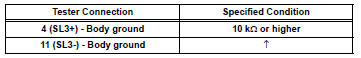

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

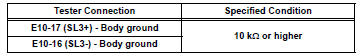

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance (Check for short)

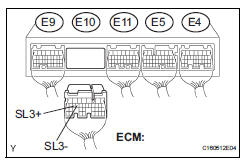

2 CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM)

(a) Connect the transmission wire connector to the transaxle.

(b) Disconnect the connector from the ECM.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance

(d) Measure the resistance according to the value(s) in the table below.

Standard resistance (Check for short)

REPLACE ECM

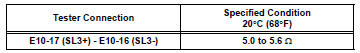

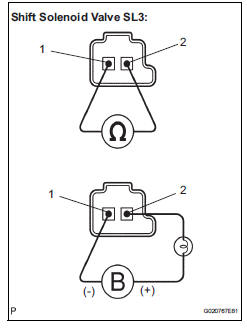

3 INSPECT SHIFT SOLENOID VALVE SL3

(a) Remove the shift solenoid valve SL3.

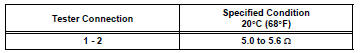

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

(c) Connect the positive (+) lead with a 21 W bulb to terminal 2 and the negative (-) lead to terminal 1 of the solenoid valve connector, then check the movement of the valve.

OK: The solenoid makes an operating sound.

REPAIR OR REPLACE TRANSMISSION WIRE

Pressure Control Solenoid "C" Performance (Shift

Solenoid Valve SL3)

Pressure Control Solenoid "C" Performance (Shift

Solenoid Valve SL3)

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear

position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shift s ...

Shift Solenoid "D" Control Circuit

Shift Solenoid "D" Control Circuit

DESCRIPTION

Shifting from 1st to 5th is performed in combination with "ON" and "OFF"

operation of the shift solenoid

valves SL1, SL2, SL3, S4 and SR which are controlled by ...

Other materials:

Customize parameters

HINT:

The following items can be customized.

NOTICE:

When the customer requests a change in a function,

first make sure that customization of the function(s) is

possible.

Be sure to record the current settings before

customizing.

When troubleshooting a function, fir ...

Open in CAN Main Bus Line

DESCRIPTION

There may be an open circuit in the CAN main bus wire and/or the DLC3 branch

wire when the resistance

between terminals 6 (CANH) and 14 (CANL) of the DLC3 is 69 Ω or higher.

Symptom

Trouble Area

Resistance between terminals 6 (CANH) and 14 (CANL) of t ...

Removal

1. REMOVE INSTRUMENT CLUSTER CENTER NO. 1 FINISH PANEL

2. REMOVE INSTRUMENT CLUSTER CENTER NO. 2

FINISH PANEL

3. REMOVE SHIFT LEVER KNOB SUB-ASSEMBLY

4. REMOVE POSITION INDICATOR HOUSING ASSEMBLY

5. REMOVE INSTRUMENT CLUSTER CENTER LOWER FINISH PANEL SUB-ASSEMBLY

6. REMOVE POWER POINT SOCKET A ...