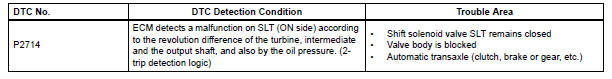

Toyota Sienna Service Manual: Pressure Control Solenoid "D" Performance (Shift Solenoid Valve SLT)

SYSTEM DESCRIPTION

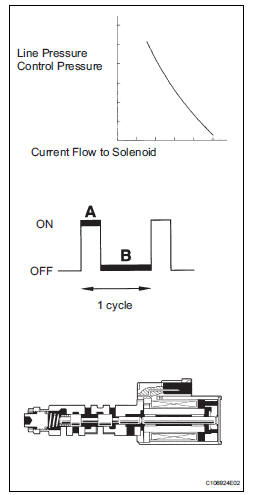

The linear solenoid valve (SLT) controls the transmission line pressure for smooth transmission operation based on signals from the throttle position sensor and the vehicle speed sensor. The ECM adjusts the duty ratio (*) of the SLT solenoid valve to control hydraulic line pressure coming from the primary regulator valve. Appropriate line pressure assures smooth shifting with varying engine outputs.

(*): Duty Ratio

The duty ratio is the ratio of the period of continuity in one cycle. For

example, if A is the period of

continuity in one cycle, and B is the period of non-continuity, then

Duty Ratio=A/(A+B) x 100(%)

MONITOR DESCRIPTION

In any forward position, when the difference between the revolutions of the turbine, Intermediate and output shaft exceeds the specified value (varies with Intermediate, output speed) determined by the ECM, the ECM illuminates the MIL and store the DTC.

When shift solenoid valve SLT remains on, the oil pressure goes down and the clutch engagement force decreases.

| NOTICE: If you continue driving under these conditions, the clutch will burn out and the vehicle will no longer be drivable. |

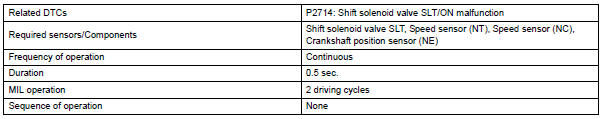

MONITOR STRATEGY

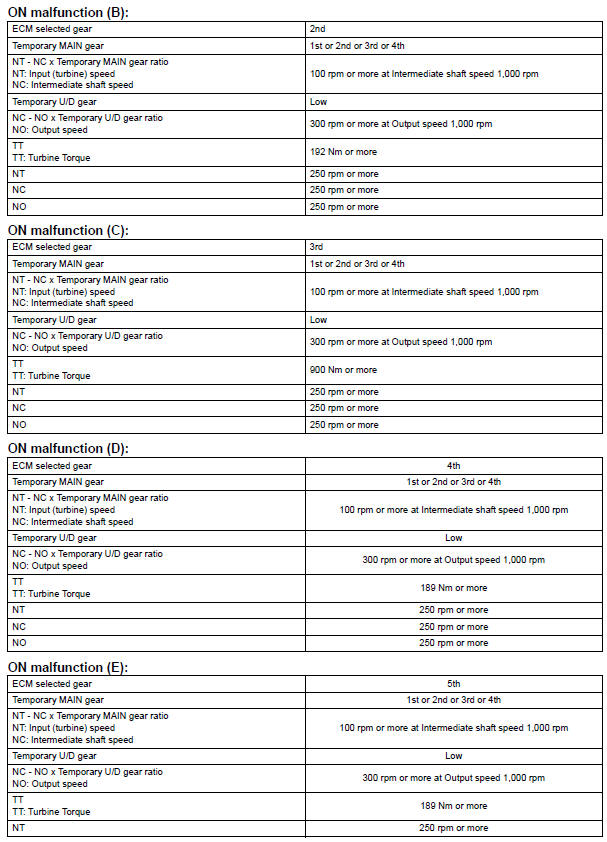

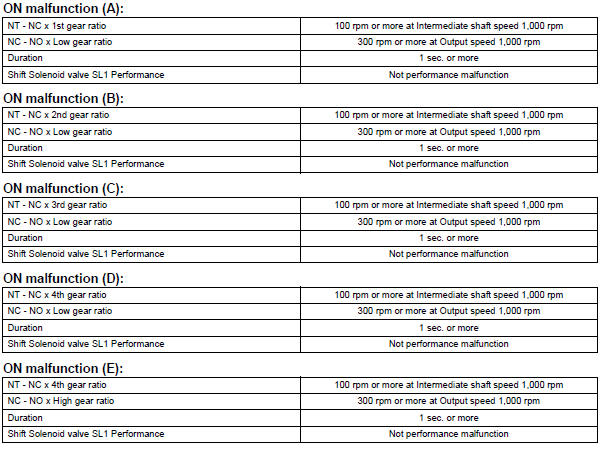

TYPICAL ENABLING CONDITIONS

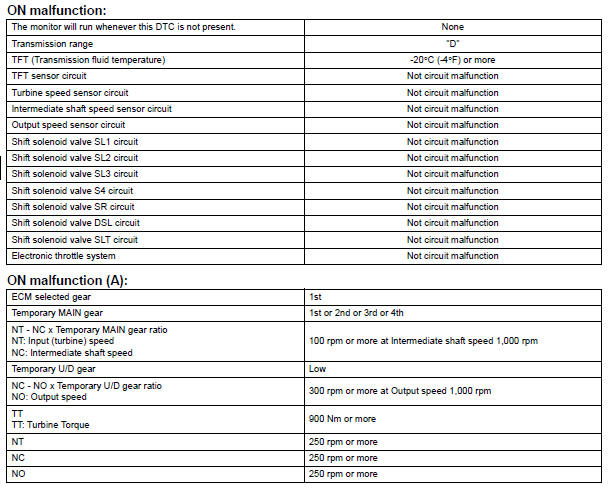

TYPICAL MALFUNCTION THRESHOLDS

[ON malfunction] Detection condition: Total accumulated time of ON malfunctions (a), (b), (c), (d) and (e) is 0.5 second or more

INSPECTION PROCEDURE

1 CHECK OTHER DTCS OUT PUT (IN ADDITION TO DTC P2714)

(a) Connect the OBD II scan tool or intelligent tester together with the CAN VIM (controller area network vehicle interface module) to the DLC3.

(b) Turn the ignition switch to the ON position and turn the OBD II scan tool or the intelligent tester main switch ON.

(c) When you use intelligent tester: Select the item "DIAGNOSIS / ENHANCED OBD II / DTC INFO / CURRENT CODES" (d) Read the DTCs using the OBD II scan tool or the intelligent tester.

Result

HINT: If any other codes besides "P2714" are output, perform the troubleshooting for those DTCs first.

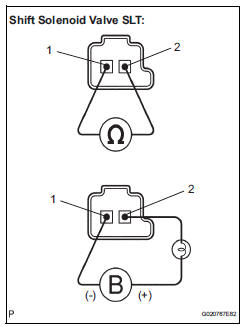

2 INSPECT SHIFT SOLENOID VALVE SLT

(a) Remove the shift solenoid valve SLT.

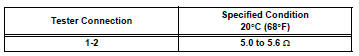

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

(c) Connect the positive (+) lead with a 21 W bulb to terminal 2 and the negative (-) lead to terminal 1 of the solenoid valve connector, then check the movement of the valve.

OK: The solenoid makes an operating sound.

3 INSPECT TRANSMISSION VALVE BODY ASSEMBLY

OK: There are no foreign objects on each valve.

4 INSPECT TORQUE CONVERTER CLUTCH ASSEMBLY

OK: The torque converter clutch operates normally.

REPAIR OR REPLACE AUTOMATIC TRANSAXLE ASSEMBLY

Shift Solenoid "E" Control Circuit

Shift Solenoid "E" Control Circuit

DESCRIPTION

Shifting from 1st to 5th is performed in combination with "ON" and "OFF"

operation of the shift solenoid

valves SL1, SL2, SL3, S4 and SR which are controlled by ...

Pressure Control Solenoid "D" Electrical (Shift

Solenoid Valve SLT)

Pressure Control Solenoid "D" Electrical (Shift

Solenoid Valve SLT)

DESCRIPTION

The linear solenoid valve (SLT) controls the transmission line pressure for

smooth transmission operation

based on signals from the throttle position sensor and the vehicle speed senso ...

Other materials:

Reassembly

1. INSTALL REAR DOOR WIRE SUB-ASSEMBLY LH

Install the wire.

NOTICE:

When installing the wire, push the areas where

the clips are installed in order to prevent

damage and deformation.

Install the 2 screws.

2. INSTALL REAR DOOR LOCK ASSEMBLY LH

Apply MP grease to the slidi ...

Vvt sensor

COMPONENTS

ON-VEHICLE INSPECTION

1. CHECK VVT SENSOR OUTPUT VOLTAGE

(a) Turn the ignition switch to the ON position.

(b) Check the voltage between the specified terminal

and body ground.

Standard voltage

(c) While turning the crankshaft pulley by hand,

measure the voltage betwe ...

Diagnostic trouble code chart

If a malfunction code is displayed during the DTC check,

check the circuit listed for that code in the table below.

(Proceed to the page given for that circuit.)

BACK DOOR CLOSER SYSTEM

DTC No.

Detection Item

Trouble Area

B2215

Back Door Closer Switch

...