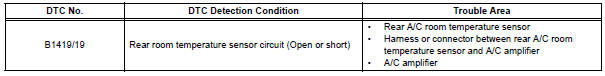

Toyota Sienna Service Manual: Rear Room Temperature Sensor Circuit

DESCRIPTION

This sensor detects the rear cabin temperature that is used as the basis for

temperature control and

sends a signal to the A/C amplifier.

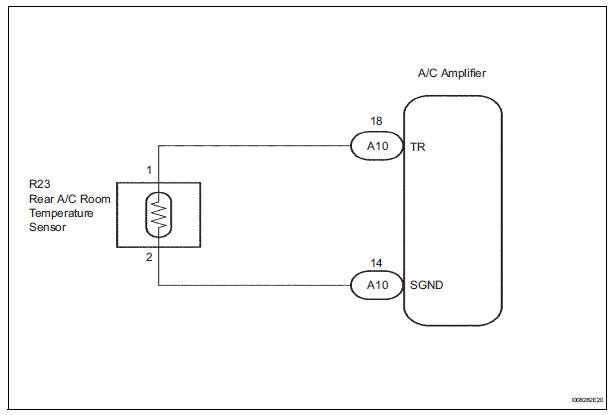

WIRING DIAGRAM

INSPECTION PROCEDURE

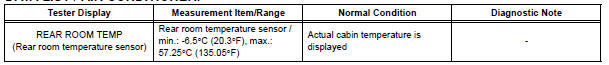

1 READ VALUE OF INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the intelligent tester main switch on.

(c) Select the item below in the DATA LIST, and read the display on the intelligent tester.

DATA LIST / AIR CONDITIONER:

OK: The display is as specified in the normal condition column.

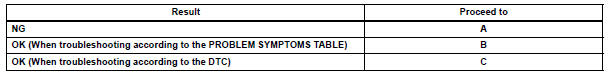

Result

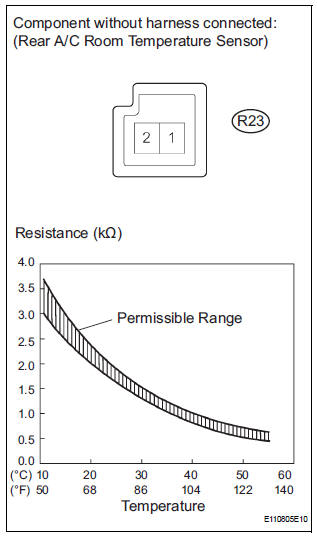

2 INSPECT REAR A/C ROOM TEMPERATURE SENSOR

(a) Remove the rear A/C room temperature sensor.

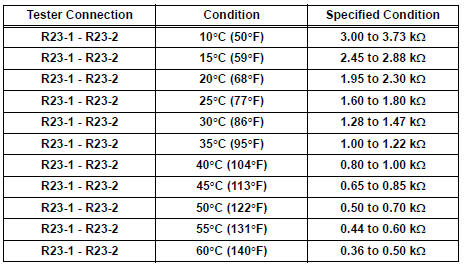

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

NOTICE:

- Hold the sensor only by its connector. Touching the sensor may change the resistance value.

- When measuring, the sensor temperature must be the same as the rear cabin temperature.

HINT: As the temperature increases, the resistance decreases (see the graph).

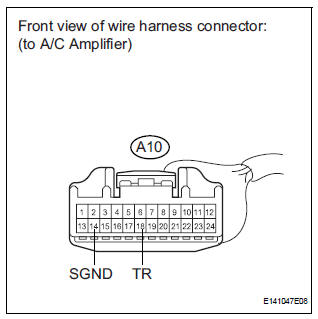

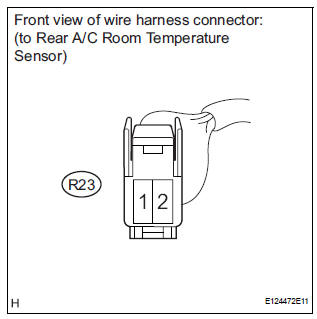

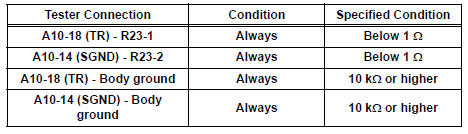

3 CHECK HARNESS AND CONNECTOR (REAR A/C ROOM TEMPERATURE SENSOR - A/C AMPLIFIER)

(a) Disconnect the connector from the A/C amplifier.

(b) Disconnect the connector from the rear A/C room temperature sensor.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance

REPLACE A/C AMPLIFIER

Rear evaporator temperature sensor circuit

Rear evaporator temperature sensor circuit

DESCRIPTION

The rear evaporator temperature sensor is installed on the rear evaporator.

It detects the rear evaporator

temperature. The sensor sends a signal to the A/C amplifier. The resistance o ...

Solar Sensor Circuit (Passenger Side)

Solar Sensor Circuit (Passenger Side)

DTC B1421/21 Solar Sensor Circuit (Passenger Side)

DESCRIPTION

The solar sensor, which is installed on the upper side of the instrument

panel, detects sunlight and

controls the air conditioni ...

Other materials:

Air Mix Damper Position Sensor Circuit (Passenger Side)

DESCRIPTION

This sensor detects the position of the air mix control servo motor (air mix

damper) and sends the

appropriate signals to the A/C amplifier. The position sensor is built in the

air mix control servo motor. The

position sensor's resistance changes as the air mix control servo m ...

Customize parameters

HINT:

The following items can be customized.

NOTICE:

After confirming whether the items requested by the

customer are applicable or not for customization,

perform customizing operations.

Be sure to record the current settings before

customization.

When troubleshooti ...

Changing the rear setting

Adjusting the temperature setting

Press the ŌĆ£REARŌĆØ button (indicator and rear temperature on the

display on).

Turn the ŌĆ£REAR TEMPŌĆØ dial clockwise to increase the temperature

and counterclockwise to decrease the temperature.

The air conditioning system switches between individual ...