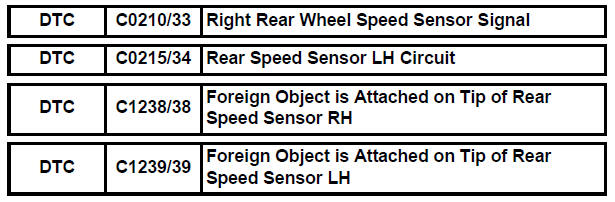

Toyota Sienna Service Manual: Right Rear Wheel Speed Sensor Signal

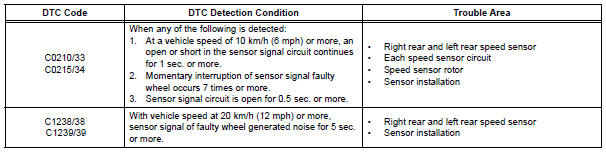

DESCRIPTION

Refer to DTCs C0200/31, C0205/32, C1235/35 and C1236/36 (See page BC-92).

HINT:

- DTC C0210/33 and C1238/38 are for the right rear speed sensor.

- DTC C0215/34 and C1239/39 are for the left rear speed sensor.

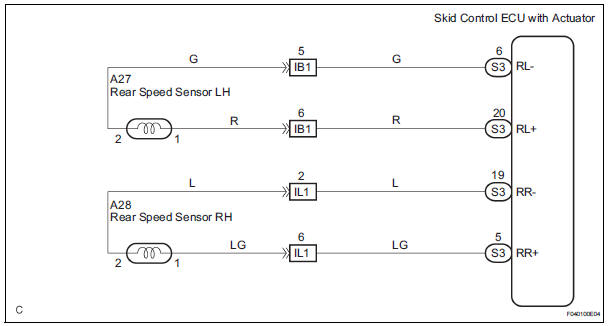

WIRING DIAGRAM

INSPECTION PROCEDURE

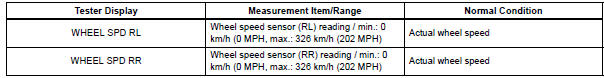

1 READ VALUE ON INTELLIGENT TESTER (REAR SPEED SENSOR)

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine.

(c) Select the DATA LIST mode on the intelligent tester.

ABS / VSC:

(d) Check that there is no difference between the speed value output from the speed sensor displayed by the intelligent tester and the speed value displayed on the speedometer when driving the vehicle

OK: There is almost no difference in the displayed speed value.

HINT: There is tolerance of +- 10 % in the speedometer indication.

2 CHECK SPEED SENSOR AND SENSOR ROTOR SERRATIONS

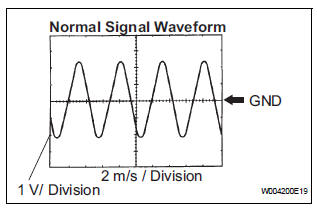

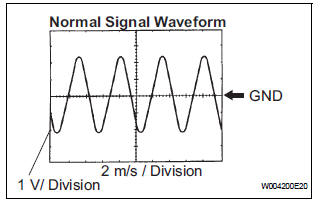

(a) INSPECTION USING OSCILLOSCOPE:

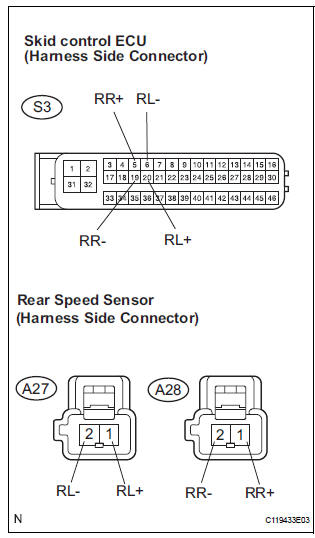

(1) Connect the oscilloscope to terminals RR+ - RR- or RL+ - RL- of the skid control ECU.

(2) Drive the vehicle at approximately 19 mph (30 km/ h), and check the signal waveform.

OK: A waveform as shown in a figure should be output.

HINT:

- As vehicle speed (wheel revolution speed) in creases, a cycle of the waveform narrows and the fluctuation in the output voltage becomes greater.

- hen noise is identified in the waveform on the oscilloscope, error signals are generated due to the speed sensor rotor's scratches, looseness or foreign matter attached to it.

NOTICE: When replacing the brake actuator assembly, perform zero point calibration (See page BC-70).

REPLACE BRAKE ACTUATOR ASSEMBLY

3 INSPECT REAR SPEED SENSOR

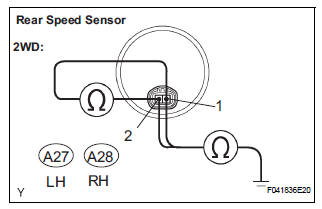

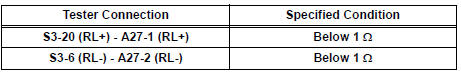

(a) 2WD

(1) Disconnect the skid control sensor connector.

(2) Measure the resistance according to the value(s) in the table below.

Standard resistance:

LH

RH

NOTICE: Check the speed sensor signal after replacement (See page BC-72).

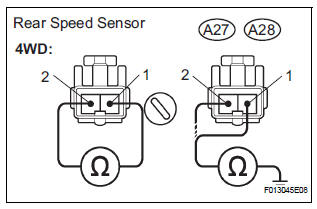

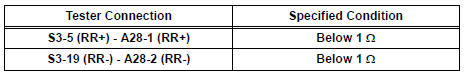

(b) 4WD

(1) Remove the seat cushion seatback.

(2) Disconnect the speed sensor connector.

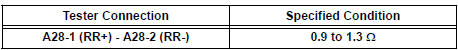

(3) Measure the resistance according to the value(s) in the table below.

Standard resistance:

LH

RH

(4) Measure the resistance according to the value(s) in the table below

Standard resistance:

LH

RH

NOTICE: Check the speed sensor signal after the replacement. (See page BC-72)

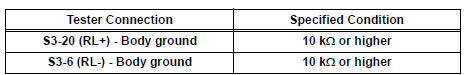

4 CHECK HARNESS AND CONNECTOR (REAR SPEED SENSOR - SKID CONTROL ECU)

(a) Disconnect the skid control ECU connector and the skid control sensor connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance:

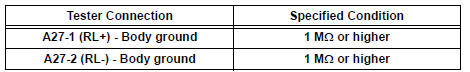

LH

RH

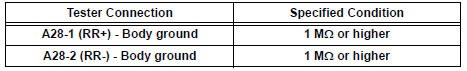

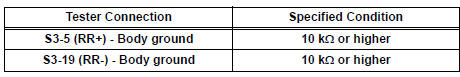

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance:

LH

RH

5 CHECK SPEED SENSOR AND SENSOR ROTOR SERRATIONS

(a) INSPECTION USING OSCILLOSCOPE

(1) Connect the oscilloscope to terminals RR+ - RR- or RL+ - RL- of the skid control ECU.

(2) Drive the vehicle at approximately 19 mph (30 km/ h), and check the signal waveform.

OK: A waveform as shown in a figure should be output.

HINT:

- As the vehicle speed (wheel revolution speed) increases, a cycle of the waveform narrows and the fluctuation in the output voltage becomes greater.

- When noise is identified in the waveform on the oscilloscope, error signals are generated due to the speed sensor rotor's scratches, looseness or foreign matter attached to it.

NOTICE: When replacing the brake actuator assembly, perform zero point calibration (See page BC-70).

REPLACE BRAKE ACTUATOR ASSEMBLY

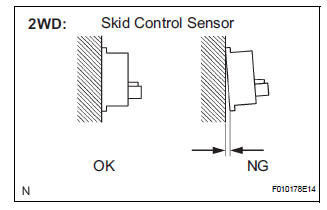

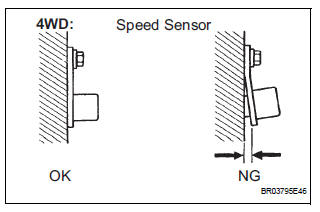

6 CHECK REAR SPEED SENSOR INSTALLATION

(a) 2WD

(1) Check the sensor installation.

OK: There is no clearance between the sensor and rear axle carrier.

(b) 4WD

(1) Check the sensor installation.

OK: There is no clearance between the sensor and rear axle carrier.

The installation bolt is tightened properly.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

NOTICE: Check the speed sensor signal after the replacement (See page BC-72).

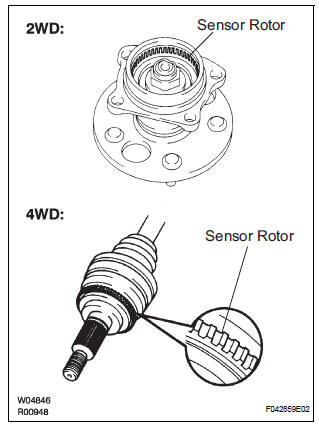

7 CHECK SPEED SENSOR ROTOR

(a) Remove the rear axle hub and bearing, or rear drive shaft (See page AH-16 for 2WD, or DS-21 for 4WD).

(b) Check the sensor rotor serrations.

OK: No scratches, missing teeth or foreign objects.

Result

NOTICE: Check the speed sensor signal after the replacement (See page BC-72).

8 CHECK REAR SPEED SENSOR TIP

(a) Remove the rear speed sensor (See page BC-190 for 2WD or BC-194 for 4WD).

(b) Check the sensor tip.

OK: No scratches or foreign matter on the sensor tip.

NOTICE:

- Check the speed sensor signal after the replacement (See page BC-72).

- When replacing the brake actuator assembly, perform zero point calibration (See page BC-70).

REPLACE BRAKE ACTUATOR ASSEMBLY

Right Front Wheel Speed Sensor Signal

Right Front Wheel Speed Sensor Signal

DESCRIPTION

The speed sensor detects wheel speed and sends the appropriate signals to the

ECU. These signals are

used to control the ABS control system. The front and rear rotors have 48

ser ...

SFR Solenoid Circuit

SFR Solenoid Circuit

DESCRIPTION

This solenoid goes on when signals are received from the ECU and controls the

pressure acting on the

wheel cylinders to control the braking force.

WIRING DIAGRAM

INSPECTI ...

Other materials:

Right Front Wheel Speed Sensor Signal

DESCRIPTION

The speed sensor detects wheel speed and sends the appropriate signals to the

ECU. These signals are

used to control the ABS control system. The front and rear rotors have 48

serrations each.

When the rotors rotate, the magnetic field emitted by the permanent magnet in

t ...

Removal

1. REMOVE BACK DOOR GARNISH CENTER

2. REMOVE BACK DOOR SIDE GARNISH LH

3. REMOVE BACK DOOR SIDE GARNISH RH

4. REMOVE BACK DOOR STRAP COVER

5. REMOVE BACK DOOR PULL STRAP

6. REMOVE BACK DOOR TRIM BOARD ASSEMBLY

7. REMOVE BACK DOOR SERVICE HOLE PLATE

8. REMOVE REAR SPOILER COVER (W/ REAR

SPOIL ...

Lost Communication with Cruise Control Front

Distance Range Sensor

DTC U0235 Lost Communication with Cruise Control Front

Distance Range Sensor

DESCRIPTION

The laser sensor and distance control ECU transmit the data for general

vehicle control and diagnosis

function along the communication line. The laser sensor transmits information

about the vehicle in fr ...