Toyota Sienna Service Manual: Slip Indicator Light Remains ON

DESCRIPTION

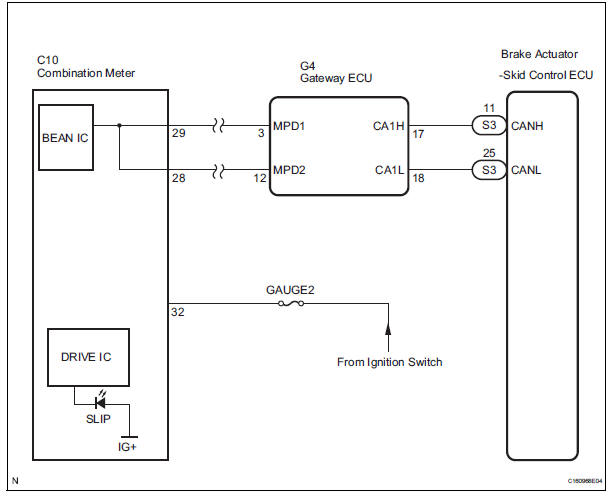

The skid control ECU is connected to the combination meter via CAN and multiplex communications.

The SLIP indicator blinks during VSC and/or TRAC operation.

When the system fails, the SLIP indicator comes on to warn the driver.

WIRING DIAGRAM

INSPECTION PROCEDURE

NOTICE: When replacing the brake actuator assembly, perform zero point calibration (See page BC-70).

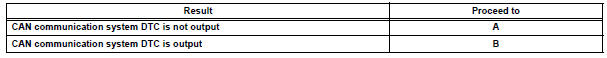

1 CHECK CAN COMMUNICATION SYSTEM

(a) Check if the CAN communication system DTC is output (See page CA-17).

Result

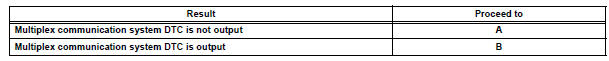

2 CHECK MULTIPLEX COMMUNICATION SYSTEM

(a) Check if the multiplex communication system DTC is output (See page MP-14).

Result

3 CHECK IF SKID CONTROL ECU CONNECTOR IS SECURELY CONNECTED

(a) Check if the skid control ECU connector is securely connected.

OK: The connector is securely connected.

4 CHECK BATTERY

(a) Check the battery voltage.

Standard voltage: 11 to 14 V

5 INSPECT COMBINATION METER ASSEMBLY

(a) Perform Active Test of the combination meter (meter CPU) using the intelligent tester (See page ME-19).

OK: The SLIP indicator light turns on or off in accordance with the intelligent tester.

HINT: If troubleshooting has been carried out according to the Problem Symptoms Table, refer back to the table and proceed to the next step before replacing the part (See page BC-79).

REPLACE BRAKE ACTUATOR ASSEMBLY

TRAC OFF Indicator Light does not Come ON

TRAC OFF Indicator Light does not Come ON

DESCRIPTION

The skid control ECU is connected to the combination meter via CAN and

multiplex communications.

When the traction OFF switch is turned on, the TRAC OFF indicator light will

come o ...

Slip Indicator Light does not Come ON

Slip Indicator Light does not Come ON

DESCRIPTION

The skid control ECU is connected to the combination meter via CAN and

multiplex communications.

The SLIP indicator blinks during VSC and/or TRAC operation.

When the system fails, ...

Other materials:

Reassembly

1. INSTALL NO. 1 COOLER THERMISTOR

(a) Install the No. 1 cooler thermistor as shown in the

illustration.

NOTICE:

Be sure to insert the thermistor only once

because reinserting it will not allow it to be

firmly secured.

When reusing the evaporator, insert the

thermistor one row ne ...

Removal

1. REMOVE CHARCOAL CANISTER PROTECTOR

(a) Remove the 6 bolts and charcoal canister protector.

2. REMOVE CHARCOAL CANISTER ASSEMBLY

(a) Disconnect the fuel tank vent hose from the

charcoal canister.

(1) Push the connector deep inside.

(2) Pinch portion A.

(3) Pull out the connector.

...

Seat Position Airbag Sensor Circuit Malfunction

DTC B1153/25 Seat Position Airbag Sensor Circuit Malfunction

DESCRIPTION

The seat position airbag sensor circuit consists of the center airbag sensor

assembly and the seat

position airbag sensor.

DTC B1153/25 is recorded when a malfunction is detected in the seat position

airbag sensor cir ...