Toyota Sienna Service Manual: Steering Angle Sensor Zero Point Malfunction

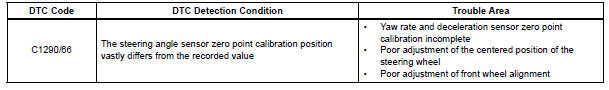

DTC C1290/66 Steering Angle Sensor Zero Point Malfunction

DESCRIPTION

The skid control ECU acquires steering angle sensor zero point every time the ignition switch is turned to the ON position and the vehicle is driven at 35 km/h (22 mph) or more for approximately 5 seconds. The ECU also stores the previous zero point.

If front wheel alignment or steering wheel position is adjusted without disconnecting the negative battery terminal, or if yaw rate and deceleration sensor zero point is not acquired after the adjustments have been completed, the skid control ECU detects the difference between the previous zero point and newly acquired zero point and outputs this DTC to indicate a poor adjustment.

Warning of the steering angle sensor zero point malfunction will be cancelled by turning the ignition switch off.

INSPECTION PROCEDURE

NOTICE: When replacing the brake actuator assembly, perform zero point calibration (See page BC-70).

1 PERFORM ZERO POINT CALIBRATION OF YAW RATE AND DECELERATION SENSOR

(a) Perform zero point calibration of the yaw rate and deceleration sensor (See page BC-70).

HINT:

- When the stored zero point of the yaw rate and deceleration sensor is erased, steering angle sensor zero point will also be erased.

- If the zero point and output value of the yaw rate and deceleration sensor and the output value of the speed sensors are not normal, steering angle sensor zero point cannot be acquired normally even if the vehicle is driven straight ahead at 35 km/h (22 mph) or more.

2 CHECK STEERING ANGLE SENSOR ZERO POINT CALIBRATION

(a) Drive the vehicle straight ahead at 35 km/h (22 mph) or more for at least 5 seconds.

(b) Check that the centered position of the steering wheel is correctly set while driving straight ahead.

HINT: If front wheel alignment and steering position are adjusted as a result of abnormal centered position of the steering wheel, acquire yaw rate and deceleration sensor zero point again after the adjustments are completed.

OK: The centered position of the steering wheel is correctly set.

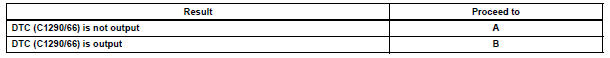

3 RECONFIRM DTC

(a) Turn the ignition switch off.

(b) Clear the DTC (See page BC-82).

(c) Start the engine.

(d) Drive the vehicle and turn the steering wheel to the right and left at the speed of 35 km/h (22 mph) or more.

(e) Check if the same DTC is recorded (See page BC-82).

Result

END

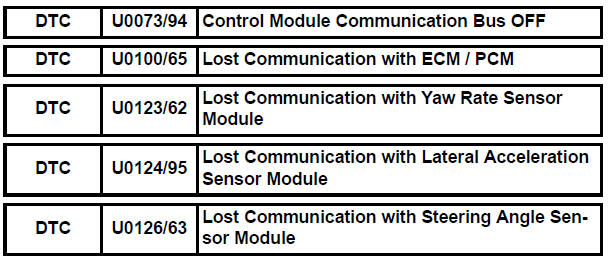

Control Module Communication Bus OFF

INSPECTION PROCEDURE

Refer to CAN communication system (See page CA-7).

Open in Pump Motor Circuit

Open in Pump Motor Circuit

DTC C1251/51 Open in Pump Motor Circuit

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

1 PERFORM ACTIVE TEST USING INTELLIGENT TESTER (ABS MOTOR RELAY)

(a) Connect the intelligent tester ...

ABS Warning Light Remains ON

ABS Warning Light Remains ON

DESCRIPTION

If any of the following is detected, the ABS warning light remains on.

The skid control ECU connectors are disconnected from the skid control

ECU.

There is a malfunction in the s ...

Other materials:

Throttle / Pedal Position Sensor / Switch "A/B"

Circuit

DTC P0120 Throttle / Pedal Position Sensor / Switch "A"

Circuit

DTC P0122 Throttle / Pedal Position Sensor / Switch "A"

Circuit Low Input

DTC P0123 Throttle / Pedal Position Sensor / Switch "A"

Circuit High Input

DTC P0220 Throttle / Pedal Position Sensor / Switch ...

Active Control Engine Mount System

DESCRIPTION

LOCATION

The Active Control Engine Mount (ACM) system decreases engine vibration at

engine idling using the

ACM VSV. The VSV is controlled by a pulse signal transmitted to the VSV from the

ECM. The frequency

of this pulse signal is matched to the engine speed to decrease engi ...

Evaporative Emission System Reference Orifice

DTC SUMMARY

HINT:

The 0.02 inch orifice is located inside the pump module.

DESCRIPTION

The circuit description can be found in the EVAP (Evaporative Emission)

System (See page ES-409).

INSPECTION PROCEDURE

Refer to the EVAP System (See page ES-412).

MONITOR DESCRIPTION

5 hours*1 af ...