Toyota Sienna Service Manual: ECM Power Source Circuit

DESCRIPTION

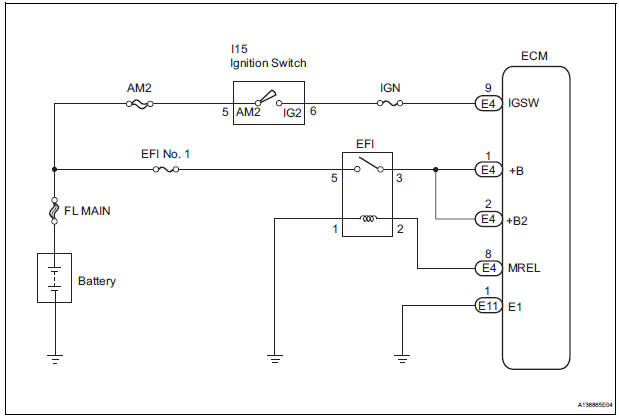

When the ignition switch is turned to the ON position, the battery voltage is applied to terminal IGSW of the ECM. The ECM MREL output signal causes a current to flow to the coil, closing the contacts of the EFI relay and supplying power to terminal +B of the ECM.

If the ignition switch is turned off, the ECM holds the EFI relay ON for a maximum of 2 seconds to allow for the initial setting of the throttle valve.

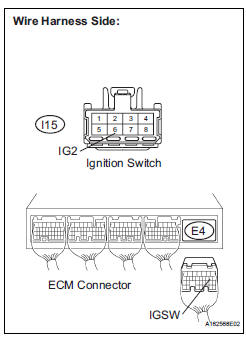

WIRING DIAGRAM

INSPECTION PROCEDURE

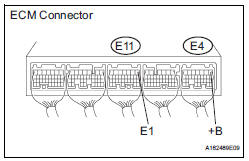

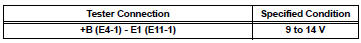

1 INSPECT ECM (+B VOLTAGE)

(a) Turn the ignition switch to the ON position.

(b) Measure the voltage according to the value(s) in the table below.

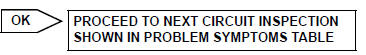

Standard voltage

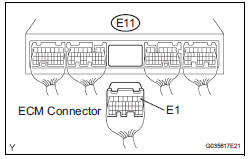

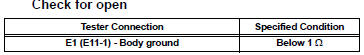

2 CHECK HARNESS AND CONNECTOR (ECM - BODY GROUND)

(a) Disconnect the E11 ECM connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance:

(c) Reconnect the ECM connector.

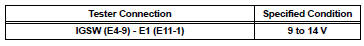

3 INSPECT ECM (IGSW VOLTAGE)

(a) Turn the ignition switch to the ON position.

(b) Measure the voltage according to the value(s) in the table below

Standard voltage

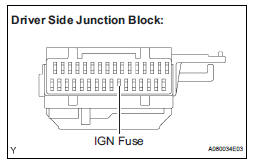

4 CHECK FUSE (IGN FUSE)

(a) Remove the IGN fuse from the driver side junction block.

(b) Measure the IGN fuse resistance.

Standard resistance: Below 1 Ω

(c) Reinstall the IGN fuse.

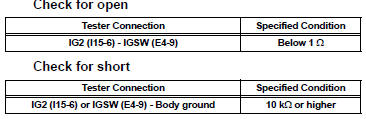

5 CHECK HARNESS AND CONNECTOR (IGNITION SWITCH - ECM)

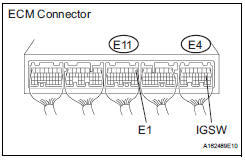

(a) Disconnect the E4 ECM connector.

(b) Disconnect the I15 ignition switch connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance:

(d) Reconnect the ECM connector.

(e) Reconnect the ignition switch connector.

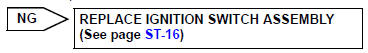

6 INSPECT IGNITION SWITCH ASSEMBLY

(a) Inspect the ignition or starter switch assembly (See page ST-16).

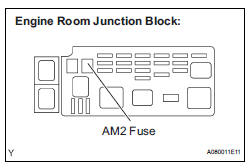

7 CHECK FUSE (AM2 FUSE)

(a) Remove the AM2 fuse from the engine room junction block.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance: Below 1 Ω

(c) Reinstall the AM2 fuse

REPAIR OR REPLACE HARNESS OR CONNECTOR (IGNITION SWITCH - BATTERY)

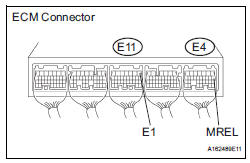

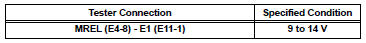

8 INSPECT ECM (MREL VOLTAGE)

(a) Turn the ignition switch to the ON position.

(b) Measure the voltage according to the value(s) in the table below.

Standard voltage

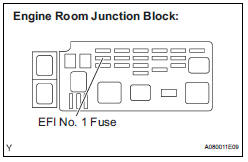

9 CHECK FUSE (EFI NO.1 FUSE)

(a) Remove the EFI No. 1 fuse from the engine room junction block.

(b) Measure the EFI No. 1 fuse resistance.

Standard resistance: Below 1 Ω

(c) Reinstall the EFI No. 1 fuse.

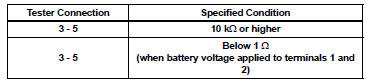

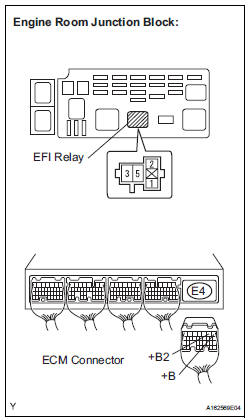

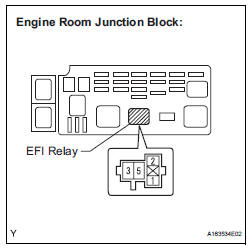

10 INSPECT RELAY (EFI RELAY)

(a) Remove the EFI relay from the engine room junction block.

(b) Measure the EFI relay resistance.

Standard resistance

(c) Reinstall the EFI relay.

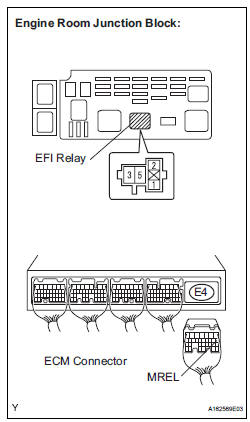

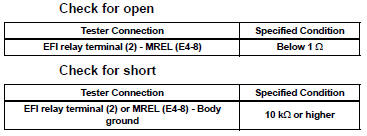

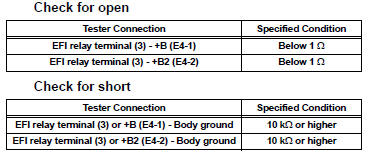

11 CHECK HARNESS AND CONNECTOR (EFI RELAY - ECM)

(a) Check the harness and connector between the EFI relay and ECM.

(1) Remove the EFI relay from the engine room junction block.

(2) Disconnect the E4 ECM connector.

(3) Measure the resistance according to the value(s) in the table below.

Standard resistance:

12 CHECK HARNESS AND CONNECTOR (EFI RELAY - ECM)

(a) Remove the EFI relay from the engine room junction block.

(b) Disconnect the E4 ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance:

(d) Reinstall the EFI relay.

(e) Reconnect the ECM connector.

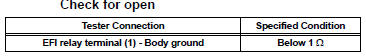

13 CHECK HARNESS AND CONNECTOR (EFI RELAY - BODY GROUND)

(a) Check the harness and connector between the EFI relay and body ground.

(1) Measure the resistance according to the value(s) in the table below.

Standard resistance :

(2) Reinstall the EFI relay.

(3) Reconnect the ECM connector.

REPAIR OR REPLACE HARNESS OR CONNECTOR (EFI RELAY - BATTERY)

EVAP System

EVAP System

RELATED DTCS

If any EVAP system DTCs are set, the malfunctioning area can be determined

using the table below.

NOTICE:

If the 0.02 inch reference pressure difference between the ...

VC Output Circuit

VC Output Circuit

DESCRIPTION

The ECM constantly uses 5 V from the battery voltages supplied to the +B

(BATT) terminal to operate the

microprocessor. The ECM also provides this power to the sensors through the VC

...

Other materials:

On-vehicle inspection

1. INSPECT BRAKE BOOSTER

(a) Air tightness check.

(1) Start the engine and stop it after 1 or 2 minutes.

Depress the brake pedal several times slowly.

HINT:

If the pedal goes down farthest at the 1st time,

and gradually rises at the 2nd or 3rd time, the

booster is airtight.

(2) Depre ...

Terminals of ECU

1. JUNCTION CONNECTOR

Junction connector

with VSC

HINT:

*1: with Dynamic laser cruise control

without VSC

CAN junction connector (with VSC)

with VSC

The connection diagram of the components which

are connected to the CAN junction connector.

2. DLC3

...

Active head restraints

When the occupant’s lower back

presses against the seatback during

a rear-end collision, the head

restraint moves slightly forward

and upward to help reduce the

risk of whiplash on the seat occupant

Active head restraints

Even small forces applied to the seatback may cause the head rest ...