Toyota Sienna Service Manual: ACIS Control Circuit

DESCRIPTION

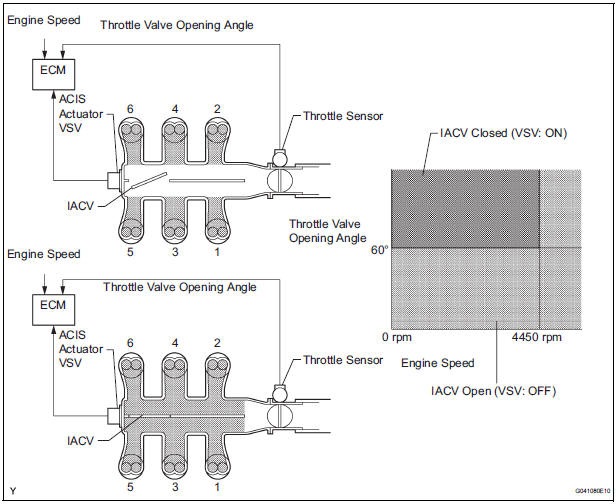

This circuit opens and closes the Intake Air Control Valve (IACV) in response to changes in the engine load in order to increase the intake efficiency (ACIS: Acoustic Control Induction System).

When the engine speed is between 0 and 4450 rpm and the throttle valve opening angle is 60° or more, the ECM supplies current to the VSV (ON status), to close the IACV. Under other conditions, the VSV is usually OFF and the IACV is open.

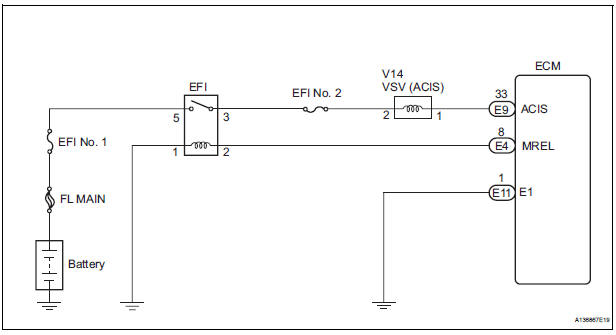

WIRING DIAGRAM

INSPECTION PROCEDURE

1 PERFORM ACTIVE TEST BY INTELLIGENT TESTER (OPERATE VSV FOR ACIS)

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and turn the intelligent tester on.

(c) Select the following menu items: DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST / INTAKE CTL VSV1. Operate the VSV for AICS.

OK: Operational noise can be heard.

2 CHECK INTAKE AIR CONTROL VALVE (OPERATION)

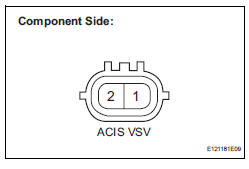

(a) Disconnect the V14 VSV for ACIS connector.

(b) Apply battery voltage between the terminals of the air intake valve connector.

(c) Check the air intake valve operation.

OK: Operational noise can be heard.

(d) Reconnect the VSV for ACIS connector.

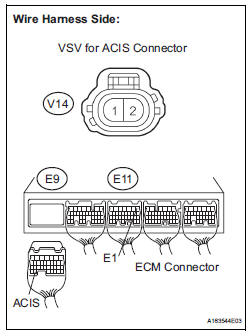

3 CHECK HARNESS AND CONNECTOR (VSV FOR ACIS - ECM)

(a) Check the wire harness and connectors between the VSV for ACIS and ECM.

(1) Disconnect the V14 VSV for ACIS connector.

(2) Disconnect the E9 ECM connector.

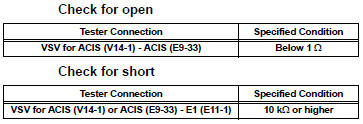

(3) Measure the resistance according to the value(s) in the table below.

Standard resistance :

(4) Reconnect the VSV for ACIS connector.

(5) Reconnect the ECM connector.

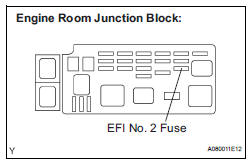

4 INSPECT FUSE (EFI NO. 2 FUSE)

(a) Check the EFI No. 2 fuse.

(1) Remove the EFI No. 2 fuse from the engine room junction block.

(2) Measure the EFI No. 2 fuse resistance.

Standard resistance: Below 1 Ω

(3) Reinstall the EFI No. 2 fuse.

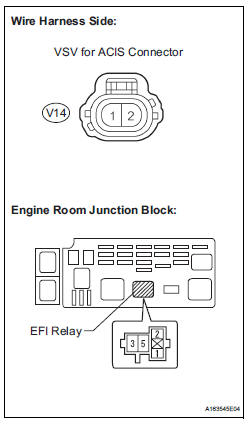

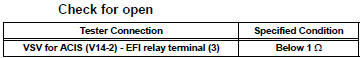

5 CHECK HARNESS AND CONNECTOR (VSV FOR ACIS - EFI RELAY)

(a) Check the wire harness between the VSV for ACIS connector and EFI relay.

(1) Remove the EFI relay from the engine room junction block.

(2) Disconnect the V14 VSV connector.

(3) Measure the resistance according to the value(s) in the table below.

Standard resistance :

(4) Reinstall the EFI relay.

(5) Reconnect the VSV connector.

CHECK ECM POWER SOURCE CIRCUIT (See page ES-437)

Cranking Holding Function Circuit

Cranking Holding Function Circuit

DESCRIPTION

The system detects the ignition switch's starting signal (STSW) and then

supplies current to the starter

until the ECM judges that the engine has started successfully. The purpose is t ...

Air Intake Control Circuit

Air Intake Control Circuit

DESCRIPTION

The air cleaner is equipped with two inlets, one of which is opened or closed

by the Air Intake Control

Valve (AICV). This system reduces intake noise and increases engine power at

l ...

Other materials:

For front passenger side

ON-VEHICLE INSPECTION

1. INSPECT AIR MIX CONTROL SERVO MOTOR

(a) Remove the air mix control servo motor.

(b) Connect the positive (+) lead from the battery to

terminal 4 and negative (-) lead to terminal 5, then

check that the lever turns to "COOL" side smoothly.

(c) Connect ...

Differential oil

Adjustment

1. INSPECT DIFFERENTIAL OIL

(a) Stop the vehicle on the level place.

(b) Remove the differential filler plug and gasket.

(c) Check that the oil surface is within 5 mm (0.20 in.)

from the lowest position of the inner surface of the

differential filler plug opening.

NOTICE:

...

No. 1 Ultrasonic sensor

COMPONENTS

REMOVAL

1. REMOVE FRONT FENDER LINER LH

2. REMOVE FRONT FENDER LINER RH

3. REMOVE FRONT BUMPER COVER

4. REMOVE REAR BUMPER COVER (2)

5. REMOVE NO. 1 ULTRASONIC SENSOR RETAINER

Remove the No. 1 ultrasonic sensor retainer as

shown in the illustration

6. REMOVE ...