Toyota Sienna Service Manual: Clearance Warning ECU Power Source Circuit

DESCRIPTION

This circuit provides power to the clearance warning ECU.

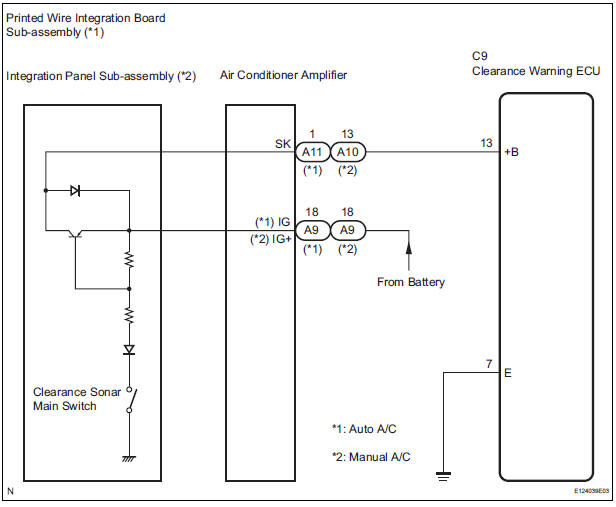

WIRING DIAGRAM

INSPECTION PROCEDURE

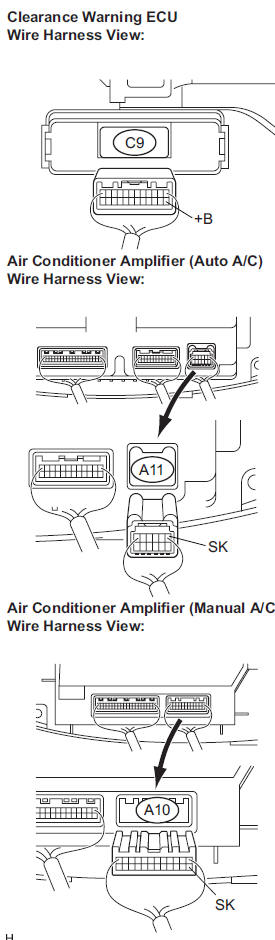

1 CHECK HARNESS AND CONNECTOR (CLEARANCE WARNING ECU - AIR CONDITIONER AMPLIFIER)

- Disconnect the connectors from the clearance warning ECU C9 and air conditioner amplifier connector A10 or A11.

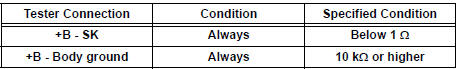

- Measure the resistance according to the value(s) in the table below.

Standard resistance

2 CHECK HARNESS AND CONNECTOR (CLEARANCE WARNING ECU - BODY GROUND)

- Measure the resistance according to the value(s) in the table below.

Standard resistance

3 INSPECT CLEARANCE WARNING ECU

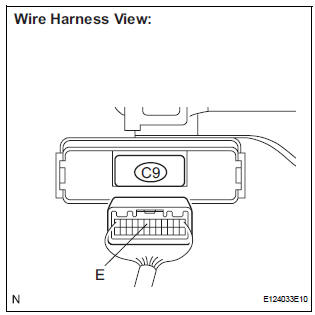

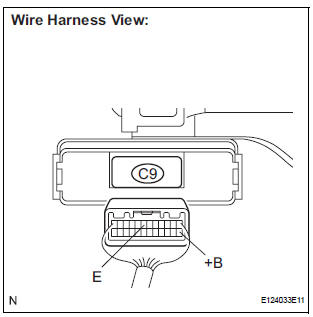

- Disconnect the clearance warning ECU connector.

- Turn the ignition switch ON.

- Turn the clearance sonar main switch ON.

- Measure the voltage between terminals +B and E of the ECU.

Standard voltage: 10 to 14 V

Result

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

4 INSPECT PRINTED WIRE INTEGRATION BOARD SUB-ASSEMBLY

- Check that the malfunction disappears when a known good printed wire integration board sub-assembly is installed.

OK: Malfunction disappears

REPLACE PRINTED WIRE INTEGRATION BOARD SUB-ASSEMBLY

5 INSPECT INTEGRATION PANEL SUB-ASSEMBLY

- Check that the malfunction disappears when a known good integration panel sub-assembly is installed.

OK: Malfunction disappears.

REPLACE INTEGRATION PANEL SUB-ASSEMBLY

No. 1 Clearance Warning Buzzer Circuit

No. 1 Clearance Warning Buzzer Circuit

DESCRIPTION

The clearance warning ECU receives the ultrasonic sensor signal to sound the

front warning buzzer.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 INSPECT FRONT BUZZER

Remove the c ...

No. 2 Clearance Warning Buzzer Circuit

No. 2 Clearance Warning Buzzer Circuit

DESCRIPTION

The clearance warning ECU receives the ultrasonic sensor signal to sound the

rear warning buzzer.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK HARNESS AND CONNECTOR (CLEARANCE WAR ...

Other materials:

Suspension

SERVICE DATA

A: Ground clearance of front wheel center

B: Ground clearance of lower suspension arm No. 2 set bolt

center

C: Ground clearance of rear axle carrier bush set bolt center

D: Ground clearance of rear wheel center

TORQUE SPECIFICATIONS

TIRE AND WHEEL

SERVICE DATA

T ...

Slide Door Closer LH does not Operate

DESCRIPTION

The slide door ECU LH controls the slide door closer. In response to the

output signals from the switches

in the slide door lock, the slide door closer drives the closer motor.

HINT:

The slide door closer system operates regardless of the power slide door main

switch ON / OFF.

W ...

Rear Clearance Sonar Sensor LH Circuit

DESCRIPTION

An ultrasonic sensor consists of a sensor portion that transmits and receives

ultrasonic waves and a preamplifier

that amplifies them. The ultrasonic sensor outputs the ultrasonic waves and

sends the received

signals to the clearance warning ECU.

WIRING DIAGRAM

INSPECTION PR ...