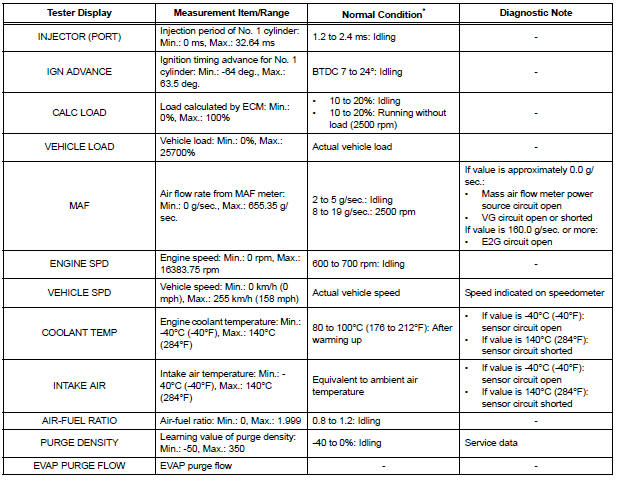

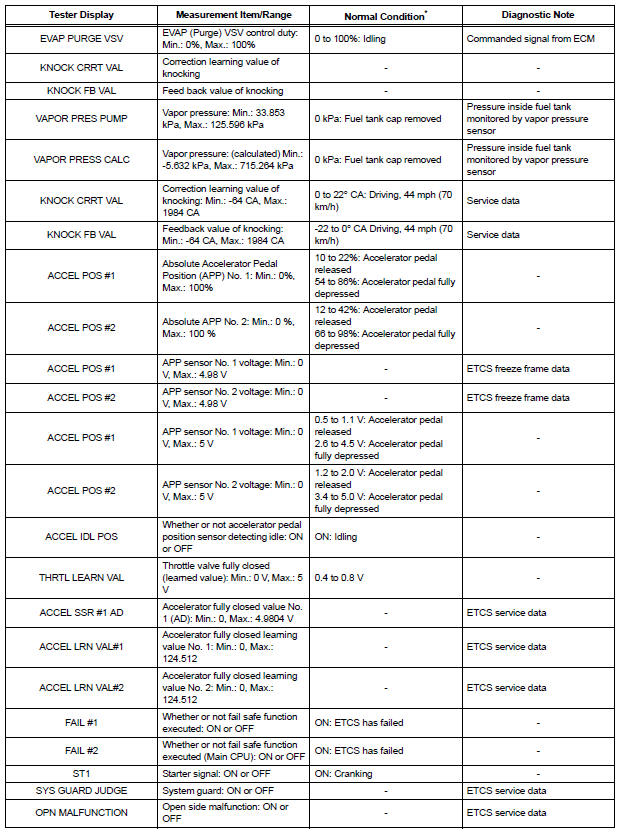

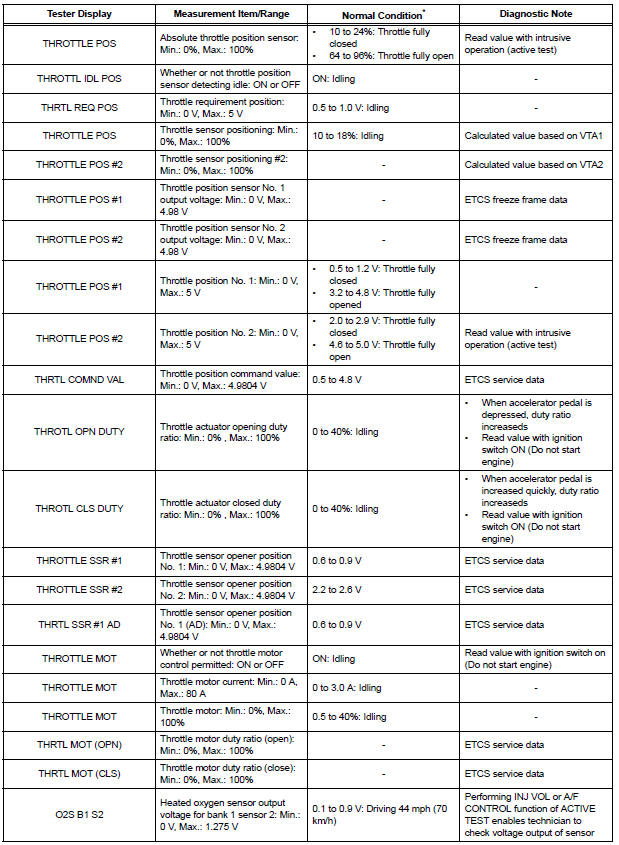

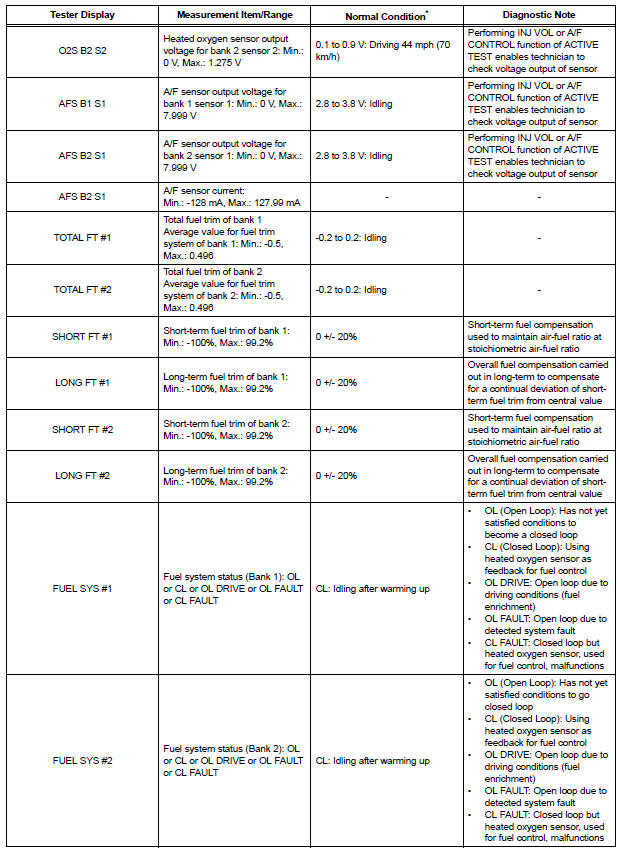

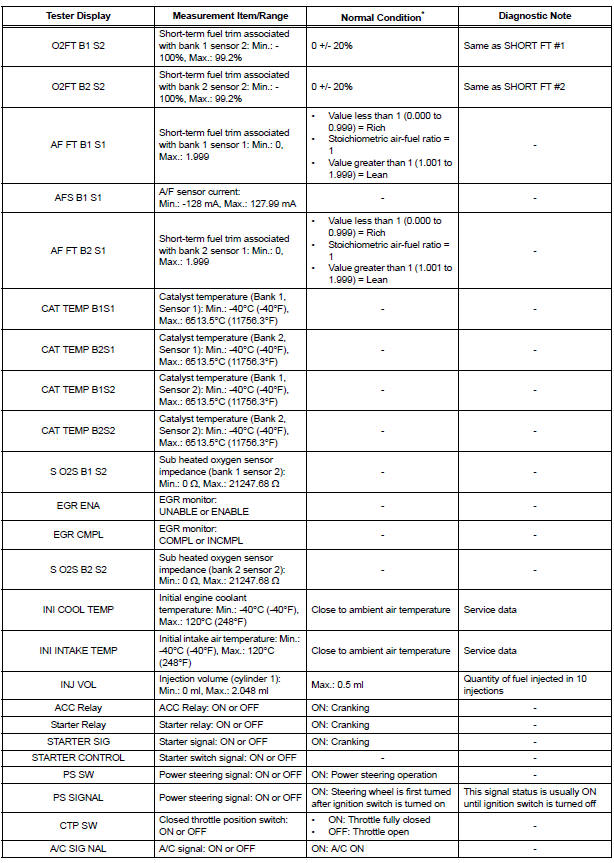

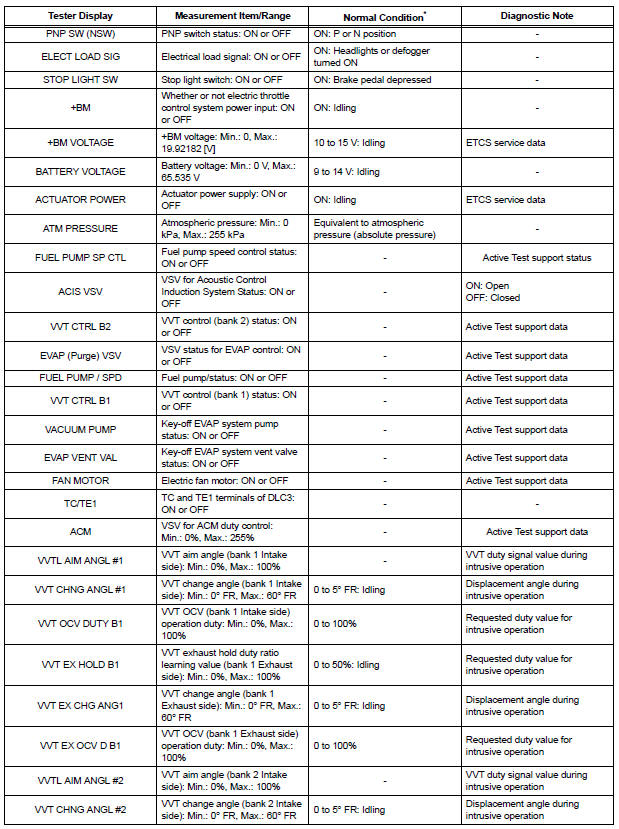

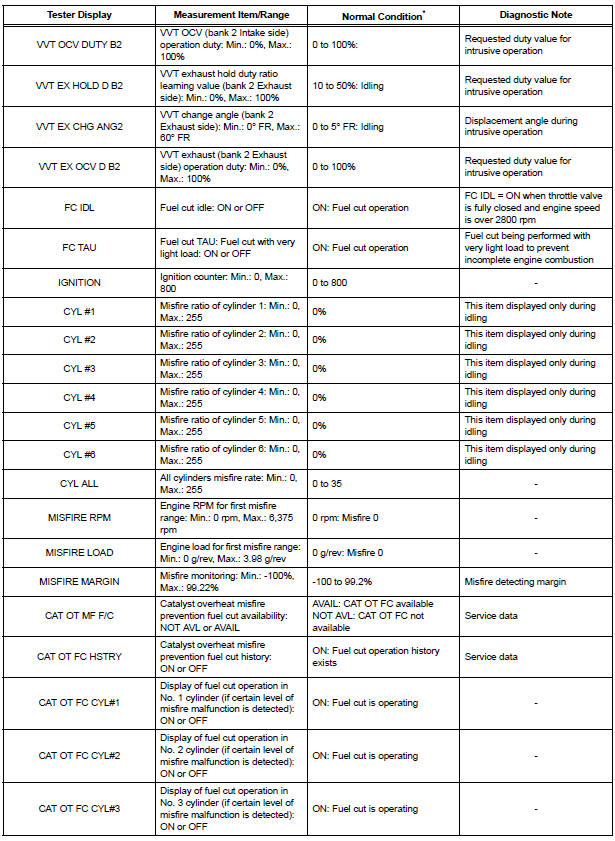

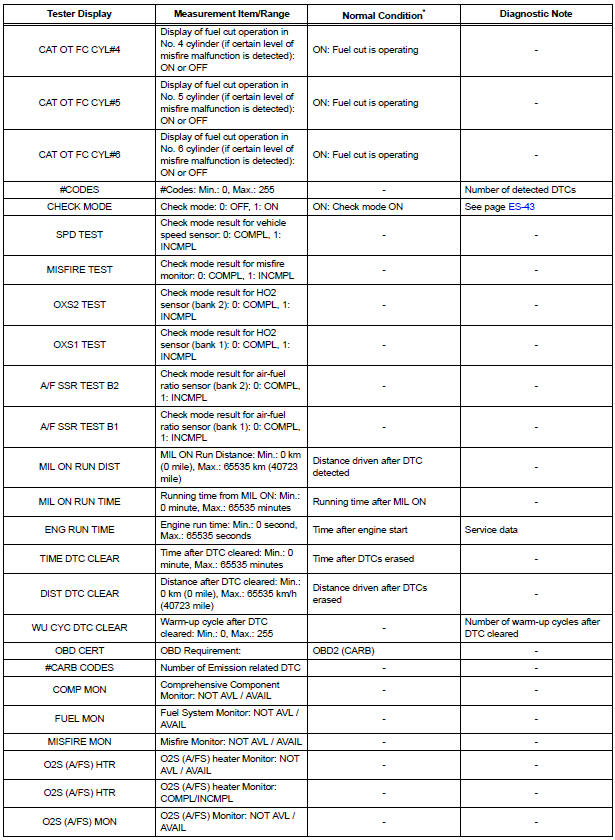

Toyota Sienna Service Manual: Data list

HINT:

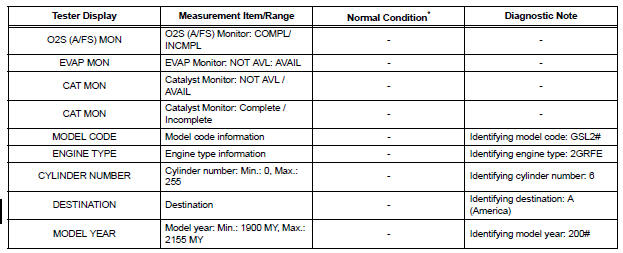

Reading the DATA LIST displayed on an intelligent tester enables values, including those of the switches, sensors, and actuators, to be checked without removing any parts. Reading the DATA LIST as the first step in troubleshooting is one method to shorten diagnostic time.

| NOTICE: In the table below, the values listed under Normal Condition are for reference only. Do not depend solely on these values when determining whether or not a part is faulty. |

(a) Warm up the engine.

(b) Turn the ignition switch off.

(c) Connect an intelligent tester to the DLC3.

(d) Start the engine.

(e) Turn the tester ON.

(f) Select the following menu items: DIAGNOSIS / ENHANCED OBD II / DATA LIST.

(g) Check the values by referring to the table below.

*: If no idling conditions are specified, the transmission gear selector lever should be in the N or P position, and the A/C switch and all accessory switches should be OFF.

Active test

Active test

HINT:

Performing an ACTIVE TEST enables components

including the relays, VSV (Vacuum Switching Valve), and

actuators, to be operated without removing any parts.

The ACTIVE TEST can be performed ...

Other materials:

Installation

1. INSTALL TRANSFER EXTENSION HOUSING TYPE T OIL SEAL

(a) Using SST(s), install anew transfer extension

housing type T oil seal to he transfer extension

housing sub-assembly at the position show in the

illustration.

SST 09325-20010

NOTICE:

Do not install the oil seal obliquely.

(b) Apply ...

Precaution

CAUTION:

The vehicle is equipped with a Supplemental Restraint

System (SRS). It consists of a driver airbag, front

passenger airbag, front seat side airbag, curtain shield

airbag, and front seat belt pretensioner. Failure to

carry out service operations in the correct sequence

co ...

Power steering fluid

Bleeding

1. BLEED POWER STEERING SYSTEM

(a) Check the fluid level (See page PS-2).

(b) Jack up the front of the vehicle and support it with

stands.

(c) Turn the steering wheel.

(1) With the engine stopped, turn the steering

wheel slowly from lock to lock several times.

(d) Lower the ...