Toyota Sienna Service Manual: ECM / PCM Processor

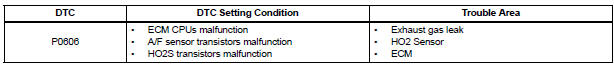

DESCRIPTION

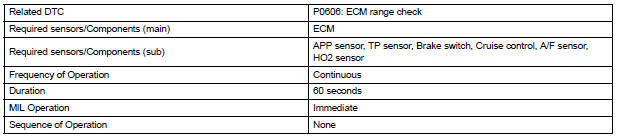

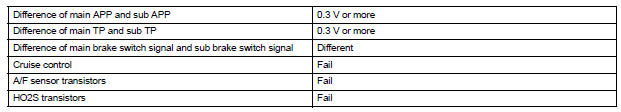

The ECM continuously monitors its internal processors (CPUs), A/F sensor transistors and heated oxygen sensor (HO2S) transistors. This self-check ensures that the ECM is functioning properly. These are diagnosed by internal "mirroring" of the main and sub CPUs to detect the processors error. If outputs from the processors deviate from the standards, the ECM will illuminate the MIL and set a DTC immediately.

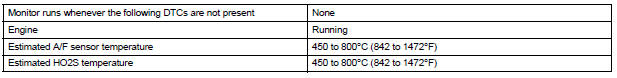

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

INSPECTION PROCEDURE

1 INSPECT FOR EXHAUST GAS LEAK

(a) Allow the engine to idle.

(b) Check for exhaust gas leak around the heated oxygen sensor.

OK: No leak from the heated oxygen sensor.

2 CHECK HEATED OXYGEN SENSOR

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and turn the tester on.

(c) Warm up the engine at an engine speed of 2500rpm for approximately 90 seconds.

(d) Enter the following menus: DIAGNOSIS / ENHANCED II / ACTIVE TEST / A/F CONTROL.

(e) Perform the A/F CONTROL operation with the engine in an idling condition (press the RIGHT or LEFT button to change the fuel injection volume).

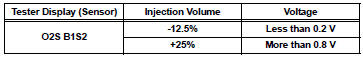

(f) Monitor the voltage outputs of the HO2 sensors (O2S B1S2) displayed on the tester.

HINT:

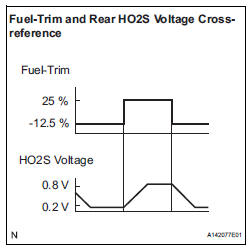

- The A/F CONTROL operation lowers the fuel injection volume by 12.5% or increases the injection volume by 25%.

- Each sensor reacts in accordance with increases in the fuel injection volume.

Standard voltage

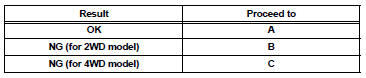

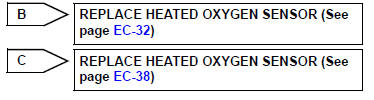

Result

3 CHECK WHETHER DTC OUTPUT RECURS (IN ADDITION TO DTC P0606)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Clear the DTC.

(e) Turn the ignition switch off.

(f) Disconnect the battery negative terminal and wait for 1 minute.

(g) Connect the battery negative terminal.

(h) Start the engine.

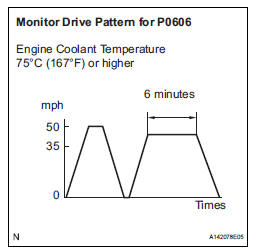

(i) Perform the drive pattern.

(1) Warm up the engine.

(2) Accelerate the vehicle to 50 mph (80 km/h) and stop the vehicle.

(3) Drive the vehicle at 35 to 50 mph (60 to 80 km/h) for 5 minutes or more.

(j) Enter the following menus: DIAGNOSIS / ENHANCED II / DTC INFO / CURRENT CODES.

(k) Read the DTCs.

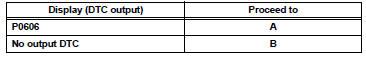

Result

REPLACE ECM (See page ES-498)

Internal Control Module Random Access Memory (RAM) Error

Internal Control Module Random Access Memory (RAM) Error

DESCRIPTION

The ECM continuously monitors its own internal memory status, internal

circuits, and output signals

transmitted to the throttle actuator. This self-check ensures that the ECM is

...

Control Module Performance

Control Module Performance

DESCRIPTION

The ECM continuously monitors its main and sub CPUs. This self-check ensures

that the ECM is

functioning properly. If outputs from the CPUs are different and deviate from

the sta ...

Other materials:

Crankshaft Position - Camshaft Position Correlation

DESCRIPTION

Refer to DTC P0335 (See page ES-220).

MONITOR DESCRIPTION

DTC P0016 and P0018

The ECM optimizes the valve timing by using the VVT (Variable Valve Timing)

system to control the intake

camshaft. The VVT system includes the ECM, the Oil Control Valve (OCV) and the

VVT contr ...

Reassembly

1. APPLY HIGH TEMPERATURE GREASE

(a) Apply the high temperature grease to the surface on

which the shoe and backing plate attach.

2. INSTALL PARKING BRAKE SHOE LEVER LH

(a) Install the shoe lever and shim to the rear shoe with

a new C-washer.

(b) Using a feeler gauge, measure the clearance.

...

Steering Pad Switch Circuit

DESCRIPTION

This circuit sends an operation signal from the steering pad switch to the

radio receiver.

If there is an open in the circuit, the navigation system cannot be operated

using the steering pad switch.

If there is a short in the circuit, the resulting condition is the same as if ...