Toyota Sienna Service Manual: Engine Coolant Temperature Circuit

DESCRIPTION

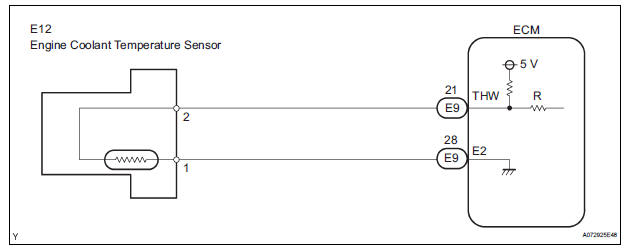

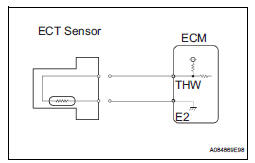

A thermistor is built into the Engine Coolant Temperature (ECT) sensor, of which the resistance value varies according to the ECT.

The structure of the sensor and its connection to the ECM are the same as those of the Intake Air Temperature (IAT) sensor.

HINT: When any of DTCs P0115, P0117 and P0118 are set, the ECM enters fail-safe mode. During fail-safe mode, the ECT is estimated to be 80°C (176°F) by the ECM. Fail-safe mode continues until a pass condition is detected.

HINT:

When any of these DTCs are set, check the ECT by selecting the following menu items on the intelligent tester: DIAGNOSIS / ENHANCED OBD II / DATA LIST / PRIMARY / COOLANT TEMP.

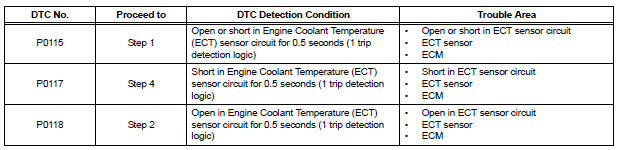

MONITOR DESCRIPTION

The Engine Coolant Temperature (ECT) sensor is used to monitor the ECT. The ECT sensor has a thermistor with a resistance that varies according to the temperature of the engine coolant. When the coolant temperature becomes low, the resistance in the thermistor increases. When the temperature becomes high, the resistance drops.

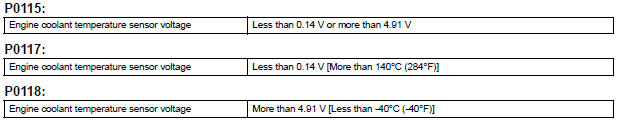

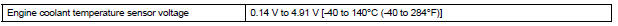

These variations in resistance are reflected in the voltage output from the sensor. The ECM monitors the sensor voltage and uses this value to calculate the ECT. When the sensor output voltage deviates from the normal operating range, the ECM interprets this as a fault in the ECT sensor and sets a DTC.

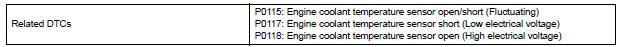

Example: If the sensor voltage output is -40°C (-40°F) for 0.5 seconds or more, the ECM determines that there is an open in the ECT sensor circuit, and sets DTC P0118. Conversely, if the voltage output is more than 140°C (284°F) for 0.5 seconds or more, the ECM determines that there is a short in the sensor circuit, and sets DTC P0117.

If the malfunction is not repaired successfully, a DTC is set 0.5 seconds after the engine is next started.

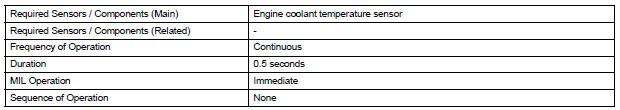

MONITOR STRATEGY

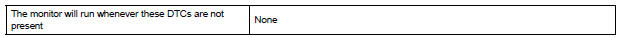

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

COMPONENT OPERATING RANGE

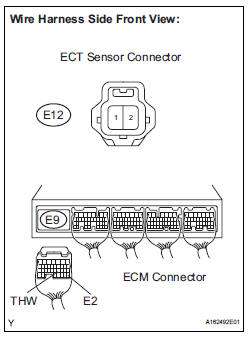

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

- If other DTCs relating to different systems that have terminal E2 as the ground terminal are output simultaneously, terminal E2 may have an open circuit.

- Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

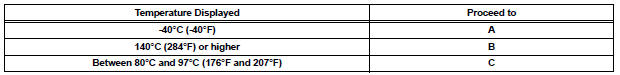

1 READ VALUE OF INTELLIGENT TESTER (ENGINE COOLANT TEMPERATURE)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Select the following menu items: DIAGNOSIS / ENHANCED OBD II / DATA LIST / PRIMARY / COOLANT TEMP.

(e) Read the value displayed on the tester.

Standard: Between 80°C and 97°C (176°F and 207°F) with warm engine.

Result

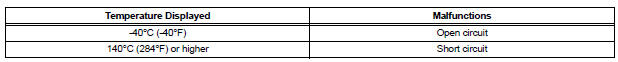

HINT:

- If there is an open circuit, the intelligent tester indicates -40°C (-40°F).

- If there is a short circuit, the intelligent tester indicates 140°C (284°F) or higher.

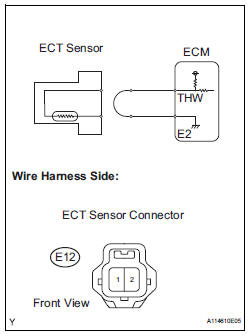

2 READ VALUE OF INTELLIGENT TESTER (CHECK FOR OPEN IN WIRE HARNESS)

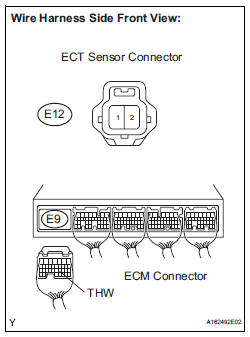

(a) Disconnect the E12 Engine Coolant Temperature (ECT) sensor connector.

(b) Connect terminals 1 and 2 of the ECT sensor connector on the wire harness side.

(c) Connect the intelligent tester to the DLC3.

(d) Turn the ignition switch to the ON position.

(e) Turn the tester on.

(f) Select the following menu items: DIAGNOSIS / ENHANCED OBD II / DATA LIST / PRIMARY / COOLANT TEMP.

(g) Read the value displayed on the tester.

Standard: 140°C (284°F) or higher

(h) Reconnect the ECT sensor connector.

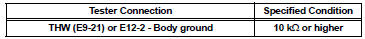

3 CHECK HARNESS AND CONNECTOR (ENGINE COOLANT TEMPERATURE SENSOR - ECM)

(a) Disconnect the E12 ECT sensor connector.

(b) Disconnect the E9 ECM connector.

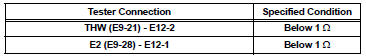

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance

(d) Reconnect the ECM connector.

(e) Reconnect the ECT connector.

REPLACE ECM (See page ES-498)

4 READ VALUE OF INTELLIGENT TESTER (CHECK FOR SHORT IN WIRE HARNESS)

(a) Disconnect the E12 ECT sensor connector.

(b) Connect the intelligent tester to the DLC3.

(c) Turn the ignition switch to the ON position.

(d) Turn the tester on.

(e) Select the following menu items: DIAGNOSIS / ENHANCED OBD II / DATA LIST / PRIMARY / COOLANT TEMP.

(f) Read the value displayed on the tester.

Standard: -40°C (-40°F)

(g) Reconnect the ECT sensor connector.

5 CHECK HARNESS AND CONNECTOR (ENGINE COOLANT TEMPERATURE SENSOR - ECM)

(a) Disconnect the E12 ECT sensor connector.

(b) Disconnect the E9 ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance

(d) Reconnect the ECT sensor connector.

(e) Reconnect the ECM connector.

REPLACE ECM (See page ES-498)

Intake Air Temperature Sensor Gradient Too High

Intake Air Temperature Sensor Gradient Too High

DESCRIPTION

The Intake Air Temperature (IAT) sensor, mounted on the Mass Air Flow (MAF)

meter, monitors the IAT.

The IAT sensor has a built-in thermistor with a resistance that varies ac ...

Engine Coolant Temperature Circuit Range / Performance Problem

Engine Coolant Temperature Circuit Range / Performance Problem

DESCRIPTION

Refer to DTC P0115 (See page ES-133).

MONITOR DESCRIPTION

The ECT sensor is used to monitor the ECT. The ECT sensor has a built-in

thermistor with a resistance

that varies ac ...

Other materials:

DVD-ROM Abnormal

DTC 44-43 DVD-ROM Abnormal

DESCRIPTION

DTC No.

DTC Detecting Condition

Trouble Area

44-43

DVD-ROM operation is abnormal.

DVD

Television display assembly

INSPECTION PROCEDURE

HINT:

After the inspection is completed, clear the ...

Operation flow

HINT:

Perform troubleshooting in accordance with the

procedures below. The following is an outline of basic

troubleshooting procedures. Confirm the troubleshooting

procedures for the circuit you are working on before

beginning troubleshooting.

VEHICLE BROUGHT TO WORKSHOP

CUSTOMER PR ...

Meter Illumination does not Dim at Night

DESCRIPTION

Confirm that the vehicle is equipped with the optitron meter, then

check this circuit.

The combination meter assembly receives a auto dimmer signal from

the body ECU by the multiplex

communication line.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK MULTIP ...