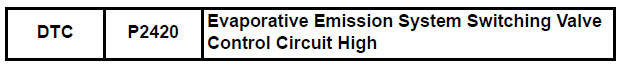

Toyota Sienna Service Manual: Evaporative Emission System Switching Valve Control Circuit High

DTC SUMMARY

DESCRIPTION

The circuit description can be found in the EVAP (Evaporative Emission) System (See page ES-404).

INSPECTION PROCEDURE

Refer to the EVAP System (See page ES-404).

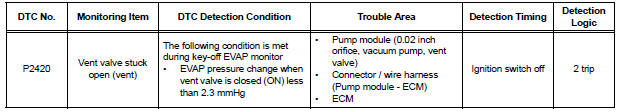

MONITOR DESCRIPTION

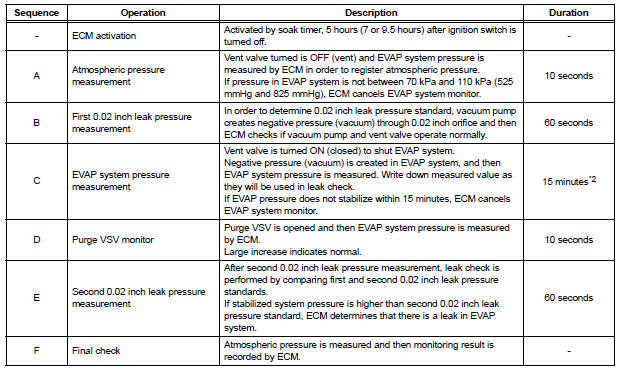

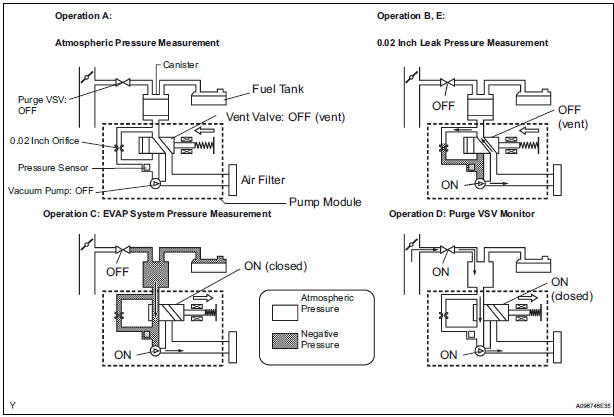

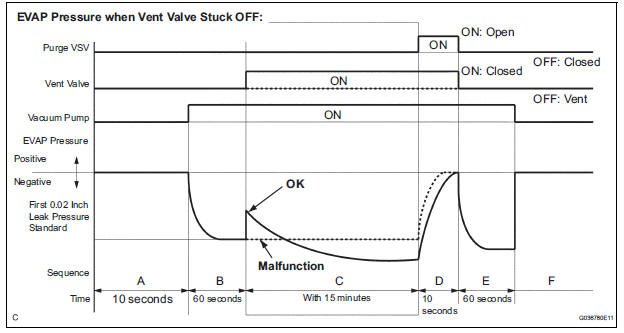

5 hours*1 after the ignition switch is turned off, the electric vacuum pump creates negative pressure (vacuum) in the EVAP (Evaporative Emission) system. The ECM monitors for leaks and actuator malfunctions based on the EVAP pressure.

HINT: *1: If the engine coolant temperature is not below 35°C (95°F) 5 hours after the ignition switch is turned off, the monitor check starts 2 hours later. If it is still not below 35°C (95°F) 7 hours after the ignition switch is turned off, the monitor check starts 2.5 hours later.

*2: If only a small amount of fuel is in the fuel tank, it takes longer for the EVAP pressure to stabilize.

The vent valve turns ON (closes) and the EVAP (Evaporative Emission) system pressure is then measured by the ECM, using the pressure sensor, to conduct an EVAP leak check. If the pressure does not increase when the vent valve is open, the ECM interprets this as the vent valve being stuck open. The ECM illuminates the MIL and sets the DTC.

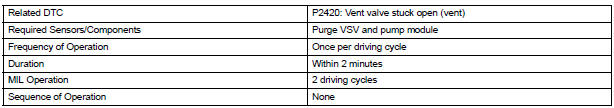

MONITOR STRATEGY

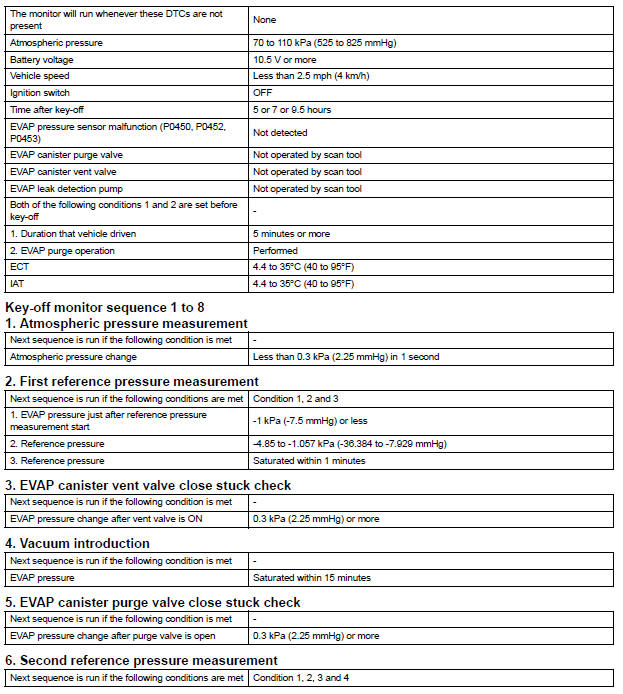

TYPICAL ENABLING CONDITIONS

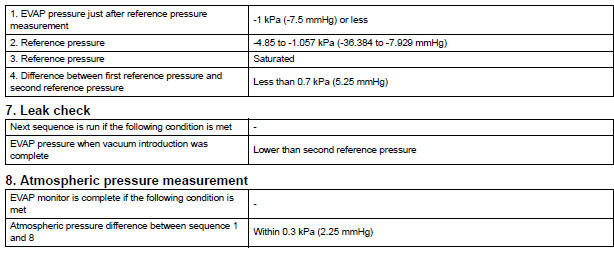

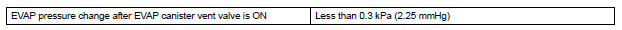

TYPICAL MALFUNCTION THRESHOLDS

MONITOR RESULT

Refer to CHECKING MONITOR STATUS (See page ES-19).

Oxygen (A/F) Sensor Pumping Current Circuit

Oxygen (A/F) Sensor Pumping Current Circuit

HINT:

Although the DTC titles say oxygen sensor, these DTCs relate to the

Air-Fuel Ratio (A/F) sensor.

Sensor 1 refers to the sensor mounted in front of the Three-Way

Catalytic Convert ...

ECM / PCM Internal Engine Off Timer Performance

ECM / PCM Internal Engine Off Timer Performance

DTC SUMMARY

DESCRIPTION

To ensure the accuracy of the EVAP (Evaporative Emission) monitor values, the

soak timer, which is built

into the ECM, measures 5 hours (+/- 15 minutes) from when the ...

Other materials:

Removal

1. DRAIN BRAKE FLUID

NOTICE:

Wash brake fluid off immediately if it adheres to any

painted surface.

2. DISCONNECT BATTERY NEGATIVE TERMINAL

3. REMOVE AIR CLEANER ASSEMBLY WITH HOSE

4. REMOVE BRAKE ACTUATOR WITH BRACKET

(a) Release the latch of the brake actuator connector to

disconnect t ...

Installation

1. INSTALL REAR DIFFERENTIAL DRIVE PINION

BEARING SPACER

(a) Install a new bearing spacer.

2. INSTALL REAR DRIVE PINION FRONT TAPERED

ROLLER BEARING

(a) Install the tapered roller bearing.

3. INSTALL REAR DIFFERENTIAL DRIVE PINION OIL SLINGER

(a) Install the oil slinger, as shown in the i ...

Detection range of the sensors

Approximately 2.0 ft. (60 cm)

Approximately 2.8 ft. (85 cm)

Approximately 5.9 ft. (180 cm)

The diagram shows the detection

range of the sensors. Note that the

sensors cannot detect obstacles

that are extremely close to the

vehicle.

The range of the sensors may

change depending ...