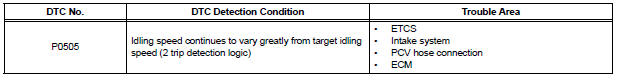

Toyota Sienna Service Manual: Idle Control System Malfunction

DESCRIPTION

The idling speed is controlled by the ETCS (Electronic Throttle Control System). The ETCS is comprised of: 1) the one valve type throttle body; 2) the throttle actuator, which operates the throttle valve; 3) the Throttle Position (TP) sensor, which detects the opening angle of the throttle valve; 4) the Accelerator Pedal Position (APP) sensor, which detects the accelerator pedal position; and 5) the ECM, which controls the ETCS.

Based on the target idling speed, the ECM controls the throttle actuator to provide the proper throttle valve opening angle.

MONITOR DESCRIPTION

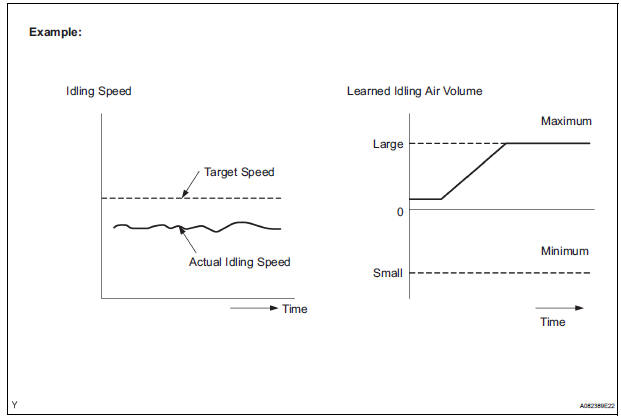

The ECM monitors the idling speed and idling air flow volume to conduct Idle Speed Control (ISC). The ECM determines that the ISC system is malfunctioning if the following conditions are met:

- The learned idling air flow volume remains at the maximum or minimum volume 5 times or more in a drive cycle.

- While driving at 6 mph (10 km/h) or more, the actual engine idling speed varies from the target idling speed by between 100 rpm and 200 rpm, 5 times or more in a drive cycle.

Example:

If the actual idling speed varies from the target idling speed by more than 200 rpm* 5 times in a drive cycle, the ECM illuminates the MIL and sets the DTC.

*: Threshold idling speed varies according to the engine load.

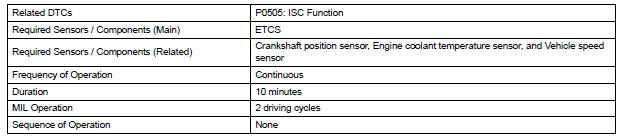

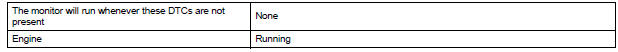

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

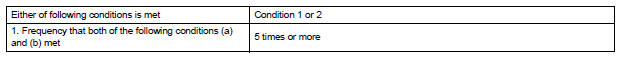

TYPICAL MALFUNCTION THRESHOLDS

INSPECTION PROCEDURE

HINT:

- The following conditions may also cause DTC P0505 to be set:

(a)The floor carpet overlapping slightly onto the accelerator pedal, causing the accelerator pedal to be slightly depressed and therefore the throttle valve position to be slightly open.

(b)The accelerator pedal being not fully released.

- Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

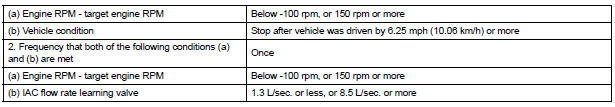

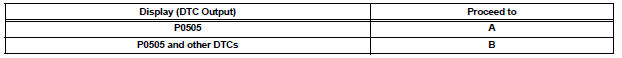

1 CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0505)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Select the following menu items: DIAGNOSIS / ENHANCED OBD II / DTC INFO / CURRENT CODES.

(e) Read the DTCs.

Result

HINT: If any DTCs other than P0505 are output, troubleshoot those DTCs first.

2 CHECK PCV HOSE CONNECTIONS

OK: PCV hose is connected correctly and is not damaged.

3 CHECK INTAKE SYSTEM

(a) Check the intake system for vacuum leakage.

OK: No leakage from intake system.

4 CHECK THROTTLE VALVE

(a) Check the throttle valve condition.

OK: No foreign objects between the throttle valve and housing.

REPLACE ECM (See page ES-498)

Brake Switch

Brake Switch

DESCRIPTION

The stop light switch is a duplex system that transmits two signals: STP and

ST1-. These two signals are

used by the ECM to monitor whether or not the brake system is working prope ...

Cold Start Idle Air Control System Performance

Cold Start Idle Air Control System Performance

DESCRIPTION

This monitor will run when the engine is started at -10 to 50°C (14 to 122°F)

of the engine coolant

temperature. The DTC will set after the engine idling for 13 seconds (2 trip

...

Other materials:

Disassembly

1. REMOVE OCCUPANT CLASSIFICATION ECU

2. REMOVE FRONT SEAT CUSHION SHIELD INNER RH

Remove the screw.

Using a screwdriver, disengage the claws and

remove the cushion shield inner.

HINT:

Tape the screwdriver tip before use.

3. REMOVE FRONT SEAT INNER BELT ASSEMBLY RH

&nbs ...

Starting the engine

Shift the shift lever to P and apply the brakes.

Touch the Toyota emblem side

of the electronic key to the

engine switch.

An alarm will sound to indicate that

the start function cannot detect the

electronic key that is touched to the

engine switch if any of the doors is

opened ...

MIL Circuit

DESCRIPTION

The MIL (Malfunction Indicator Lamp) is used to indicate vehicle malfunctions

detected by the ECM.

When the ignition switch is turned to the ON position, power is supplied to the

MIL circuit, and the ECM

provides the circuit ground which illuminates the MIL.

The MIL operation ...