Toyota Sienna Service Manual: Starter Relay Circuit High

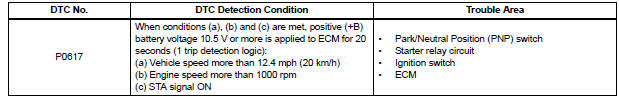

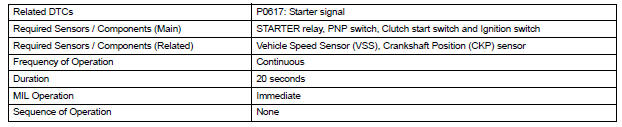

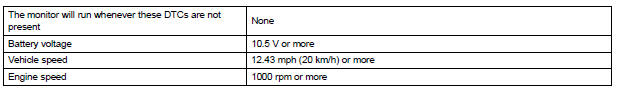

MONITOR DESCRIPTION

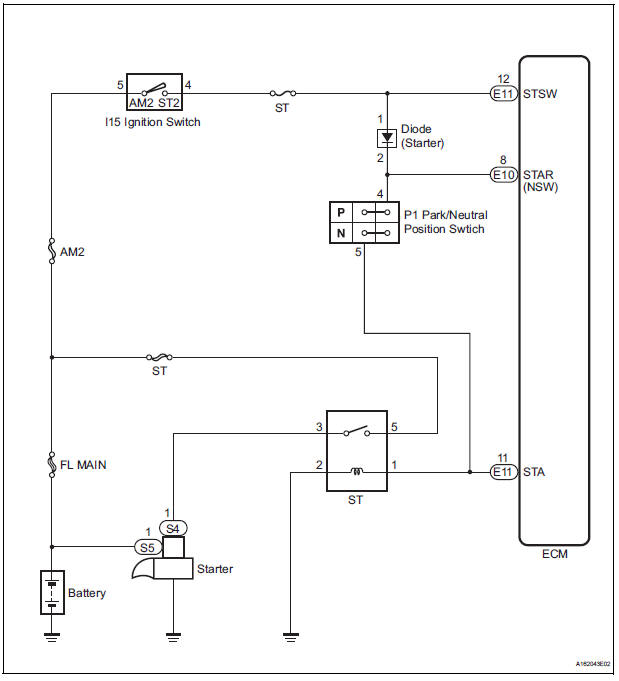

While the engine is being cranked, the positive battery voltage is applied to terminal STA of the ECM.

If the ECM detects the Starter Control (STA) signal while the vehicle is being driven, it determines that there is a malfunction in the STA circuit. The ECM then illuminates the MIL and sets the DTC.

This monitor runs when the vehicle is driven at 12.4 mph (20 km/h) for over 20 seconds.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

- The following troubleshooting flowchart is based on the premise that the engine is cranked normally. If the engine will not crank, proceed to the problem symptoms table (See page ES-27).

- Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

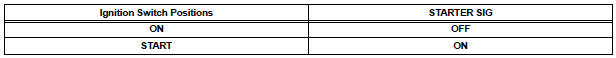

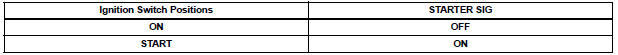

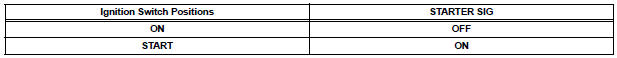

1 READ VALUE OF INTELLIGENT TESTER (STARTER SIGNAL)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the tester on.

(c) Select the following menu items: DIAGNOSIS / ENHANCED OBD II / DATA LIST / ALL / STARTER SIG.

(d) Check the value displayed on the tester when the ignition switch is turned to the ON position and START position.

OK

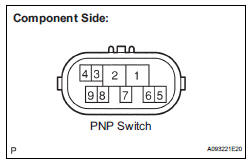

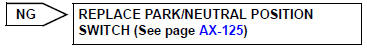

2 INSPECT PARK/NEUTRAL POSITION SWITCH

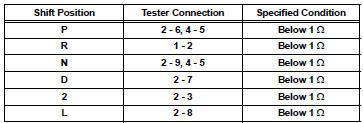

(a) Inspect the Park/Neutral Position (PNP) switch.

(1) Disconnect the P1 PNP switch connector.

(2) Measure the resistance according to the value(s) in the table below.

Standard resistance

(3) Reconnect the PNP switch connector.

3 READ VALUE OF INTELLIGENT TESTER (STARTER SIGNAL)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the tester on.

(c) Select the following menu items: DIAGNOSIS / ENHANCED OBD II / DATA LIST / ALL / STARTER SIG.

(d) Check the value displayed on the tester when the ignition switch is turned to the ON position and the START position.

OK

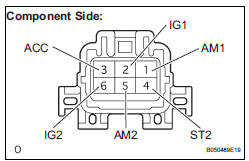

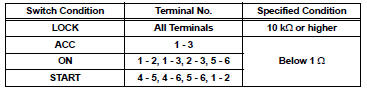

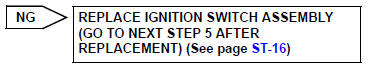

4 INSPECT IGNITION SWITCH ASSEMBLY

(a) Disconnect the I15 ignition switch connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

(c) Reconnect the ignition switch connector.

5 READ VALUE OF INTELLIGENT TESTER (STARTER SIGNAL)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the tester on.

(c) Select the following menu items: DIAGNOSIS / ENHANCED OBD II / DATA LIST / PRIMARY / STARTER SIG.

(d) Check the value displayed on the tester when the ignition switch is turned to the ON position and the START position.

OK

REPAIR OR REPLACE HARNESS OR CONNECTOR (PNP SWITCH - STA TERMINAL OF ECM)

Control Module Performance

Control Module Performance

DESCRIPTION

The ECM continuously monitors its main and sub CPUs. This self-check ensures

that the ECM is

functioning properly. If outputs from the CPUs are different and deviate from

the sta ...

VIN not Programmed or Mismatch - ECM / PCM

VIN not Programmed or Mismatch - ECM / PCM

DESCRIPTION

DTC P0630 is set when the Vehicle Identification Number (VIN) is not stored

in the Engine Control Module

(ECM) or the input VIN is not accurate. Input the VIN with the intelligent ...

Other materials:

Installation

1. INSTALL TRANSMISSION WIRE

(a) Coat the O-ring of the transmission wire connector

with ATF and install it.

(b) Install the transmission wire with the bolt.

Torque: 5.4 N*m (55 kgf*cm, 48 ft.*lbf)

2. CONNECT TRANSMISSION WIRE

(a) Coat the O-ring of the ATF temperature sensor with

...

Rear side sunshades

Rear door window

Rear quarter window

Pull the tab up.

Secure the sunshade using the hooks.

To retract the sunshade, pull the tab up slightly to unhook the sunshade,

and lower the sunshade slowly.

NOTICE

To ensure normal operation of the rear sunshades, observe ...

On-vehicle inspection

1. INSPECT DRIVE BELT

(a) Visually check the drive belt for excessive wear,

frayed cords, etc.

If any defect is found, replace the drive belt.

HINT:

Cracks on the rib side of a belt are considered

acceptable. Replace the belt if there are any

missing ribs.

2. CHECK POWER STEERING FLUID ...