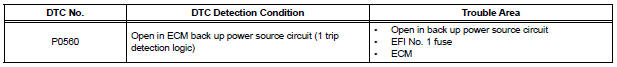

Toyota Sienna Service Manual: System Voltage

MONITOR DESCRIPTION

The battery supplies electricity to the ECM even when the ignition switch is off. This power allows the ECM to store data such as DTC history, freeze frame data and fuel trim values. If the battery voltage falls below a minimum level, these memories are cleared and the ECM determines that there is a malfunction in the power supply circuit. When the engine is next started, the ECM illuminates the MIL and sets the DTC.

HINT:

If DTC P0560 is set, the ECM does not store other DTCs.

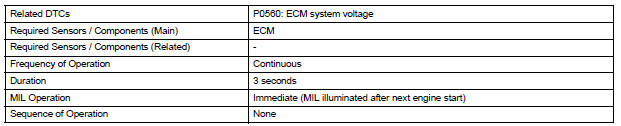

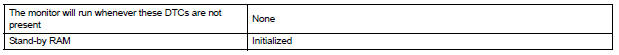

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

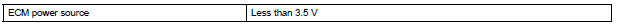

TYPICAL MALFUNCTION THRESHOLDS

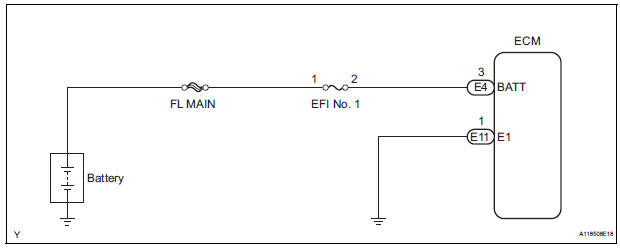

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

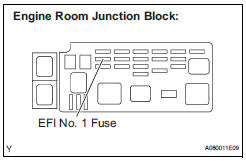

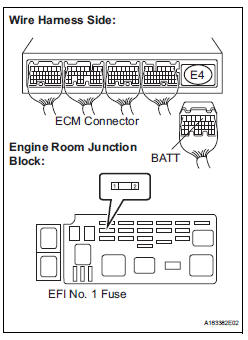

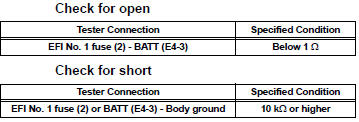

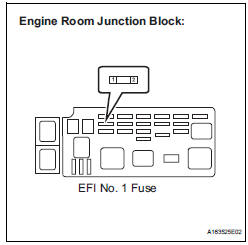

1 CHECK FUSE (EFI NO. 1 FUSE)

(a) Remove the EFI No. 1 fuse from the engine room junction block.

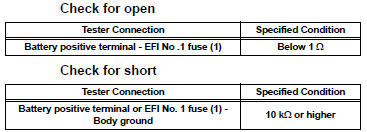

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance: Below 1 Ω

(c) Reinstall the EFI No. 1 fuse.

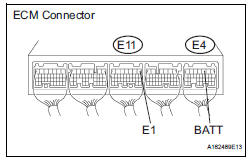

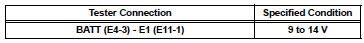

2 INSPECT ECM (BATT VOLTAGE)

(a) Measure the voltage according to the value(s) in the table below.

Standard voltage

REPLACE ECM (See page ES-498)

3 CHECK HARNESS AND CONNECTOR (ECM - EFI NO. 1 FUSE)

(a) Check the harness and the connector between the EFI No. 1 fuse and ECM.

(1) Remove the EFI No. 1 fuse from the engine room junction block.

(2) Disconnect the E4 ECM connector.

(3) Measure the resistance according to the value(s) in the table below.

Standard resistance :

(4) Reconnect the ECM connector.

(5) Reinstall the EFI No. 1 fuse.

4 CHECK HARNESS AND CONNECTOR (EFI NO. 1 FUSE - BATTERY)

(a) Check the harness and the connector between the EFI No. 1 fuse and battery.

(1) Remove the EFI No. 1 fuse from the engine room junction block.

(2) Disconnect the negative battery cable.

(3) Measure the resistance according to the value(s) in the table below.

Standard resistance:

(4) Reconnect the negative battery cable.

(5) Reinstall the EFI No. 1 fuse

5 INSPECT BATTERY

(a) Check that the battery is not depleted.

CHECK AND REPLACE ENGINE ROOM RELAY BLOCK

Cold Start Ignition Timing Performance

Cold Start Ignition Timing Performance

DESCRIPTION

This monitor will run when the engine is started at -10 to 50°C (14 to 122°F)

of the engine coolant

temperature. The DTC will set after the engine idling for 13 seconds (2 trip

...

Internal Control Module Random Access Memory (RAM) Error

Internal Control Module Random Access Memory (RAM) Error

DESCRIPTION

The ECM continuously monitors its own internal memory status, internal

circuits, and output signals

transmitted to the throttle actuator. This self-check ensures that the ECM is

...

Other materials:

Park / Neutral Position Switch Circuit

DESCRIPTION

The fold seat control ECU receives signals from the Park/Neutral position

switch and controls the seat

stowing and return operations. If the shift lever is in any position other than

P the seat cannot be operated.

If the ignition switch is in ACC or IG the seat cannot be operate ...

Evaporator temperature sensor

ON-VEHICLE INSPECTION

1. INSPECT A/C EVAPORATOR TEMPERATURE SENSOR

(a) Remove the A/C evaporator temperature sensor (A/

C thermistor).

(b) Disconnect the connector from the A/C evaporator

temperature sensor (A/C thermistor).

(c) Measure the resistance according to the value(s) in

the ...

DTC check / clear

1. DTC CHECK (USING SST CHECK WIRE)

Check the DTCs (Present trouble code).

Turn the ignition switch ON, and wait for

approximately 60 seconds.

Using SST, connect terminals TC and CG of the

DLC3.

SST 09843-18040

NOTICE:

Connect the terminals to the correct

positi ...