Toyota Sienna Service Manual: Throttle Actuator Control Motor Circuit

DESCRIPTION

The throttle actuator is operated by the ECM and opens and closes the throttle valve using gears.

The opening angle of the throttle valve is detected by the Throttle Position (TP) sensor, which is mounted on the throttle body. The TP sensor provides feedback to the ECM. This feedback allows the ECM to appropriately control the throttle actuator and monitor the throttle opening angle as the ECM responds to driver inputs.

HINT: This ETCS (Electronic Throttle Control System) does not use a throttle cable.

MONITOR DESCRIPTION

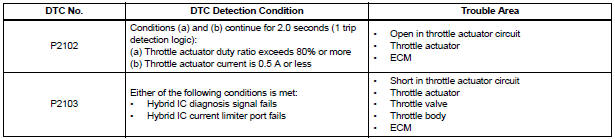

The ECM monitors the electrical current through the electronic actuator, and detects malfunctions and open circuits in the throttle actuator based on this value. If the current is outside the standard range, the ECM determines that there is a malfunction in the throttle actuator. In addition, if the throttle valve does not function properly (for example, stuck on), the ECM determines that there is a malfunction. The ECM then illuminates the MIL and sets a DTC.

Example: When the electrical current is more than 10 A, or less than 0.5 A and the throttle actuator duty ratio exceeds 80%, the ECM interprets this as the current being outside the standard range, and illuminates the MIL and sets a DTC.

If the malfunction is not repaired successfully, a DTC is set when the engine is quickly revved up to a high rpm several times after the engine has idled for 5 seconds after engine start.

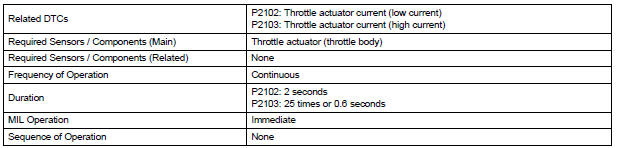

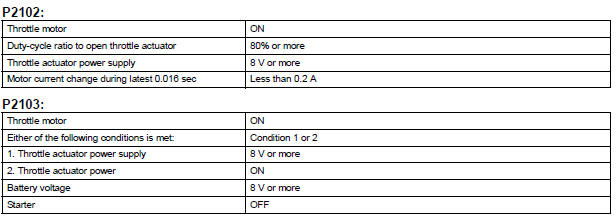

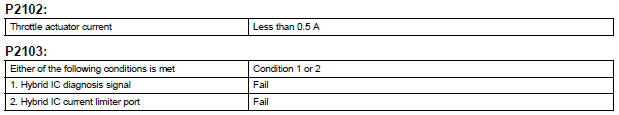

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

FAIL-SAFE

When either of these DTCs, as well as other DTCs relating to ETCS (Electronic Throttle Control System) malfunctions, is set, the ECM enters fail-safe mode. During fail-safe mode, the ECM cuts the current to the throttle actuator off, and the throttle valve is returned to a 6° throttle angle by the return spring. The ECM then adjusts the engine output by controlling the fuel injection (intermittent fuel-cut) and ignition timing, in accordance with the accelerator pedal opening angle, to allow the vehicle to continue at a minimal speed.

If the accelerator pedal is depressed gently, the vehicle can be driven slowly.

Fail-safe mode continues until a pass condition is detected, and the ignition switch is then turned off.

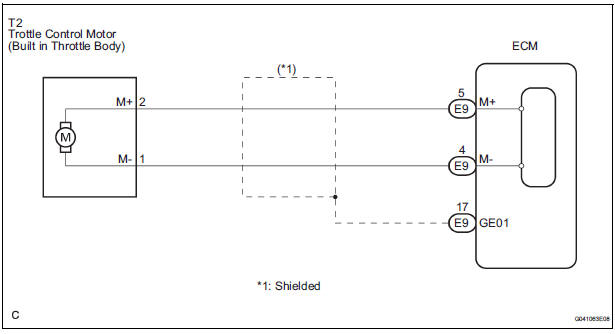

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

- Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

- The throttle actuator current (THROTTLE MOT) and the throttle actuator duty ratio (THROTTLE OPN / THROTTLE CLS) can be read using the intelligent tester. However, the ECM shuts off the throttle actuator current when the ETCS malfunctions.

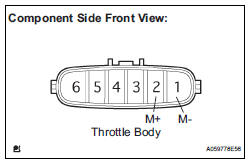

1 INSPECT THROTTLE BODY (RESISTANCE OF THROTTLE CONTROL MOTOR)

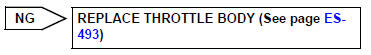

(a) Disconnect the T2 throttle body connector.

(b) Measure the resistance according to the value(s) in the table below.

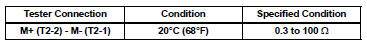

Standard resistance

(c) Reconnect the throttle body connector.

2 CHECK HARNESS AND CONNECTOR (THROTTLE CONTROL MOTOR - ECM)

(a) Disconnect the T2 throttle body connector.

(b) Disconnect the E9 ECM connector.

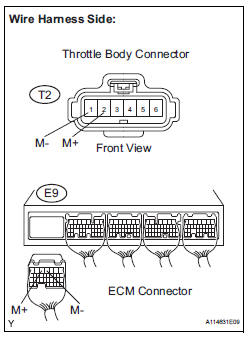

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance :

(d) Reconnect the throttle body connector.

(e) Reconnect the ECM connector.

3 INSPECT THROTTLE BODY

(a) Check for foreign objects between the throttle valve and the housing.

OK: Normal

4 INSPECT THROTTLE VALVE

(a) Check if the throttle valve opens and closes smoothly.

OK: The throttle valve opens and closes smoothly.

REPLACE ECM (See page ES-498)

Transmission Range Sensor Circuit Malfunction (PRNDL Input)

Transmission Range Sensor Circuit Malfunction (PRNDL Input)

DESCRIPTION

The park/neutral position switch detects the shift lever position and sends

signals to the ECM.

HINT:

After confirming DTC P0705, use the intelligent tester to confirm the PN ...

Throttle Actuator Control System

Throttle Actuator Control System

DESCRIPTION

The throttle actuator is operated by the ECM, and opens and closes the

throttle valve using the gears.

The opening angle of the throttle valve is detected by the Throttle Positio ...

Other materials:

Removal

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait for 90 seconds after disconnecting the cable to prevent the airbag working

2. REMOVE FRONT SEAT ASSEMBLY

HINT:

Refer to the instructions for removal of the front seat assembly (for

flat type).

Refer to the ins ...

Adjustment

1. VEHICLE PREPARATION FOR FOG LIGHT AIMING

Prepare the vehicle:

Ensure there is no damage or deformation to the

body around the fog lights.

Fill the fuel tank.

Make sure that the oil is filled to the specified

level.

Make sure that the coolant is fi ...

Initialization

1. ZERO POINT CALIBRATION

NOTICE:

Make sure that the front passenger seat is not

occupied before performing the operation.

HINT:

Perform the zero point calibration and sensitivity check if

any of the following conditions occur.

The occupant classification ECU is replaced.

Acc ...