Toyota Sienna Service Manual: Brake Switch

DESCRIPTION

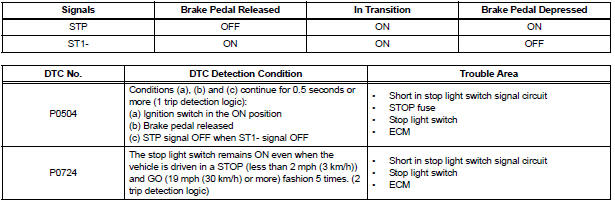

The stop light switch is a duplex system that transmits two signals: STP and ST1-. These two signals are used by the ECM to monitor whether or not the brake system is working properly. If the signals, which indicate the brake pedal is being depressed or released, are detected simultaneously, the ECM interprets this as a malfunction in the stop light switch and sets the DTC.

HINT:

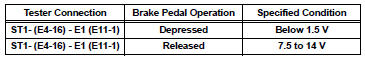

The normal conditions are as shown in the table below. The signals can be read using the intelligent tester.

MONITOR DESCRIPTION

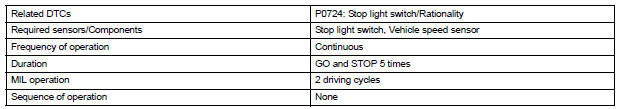

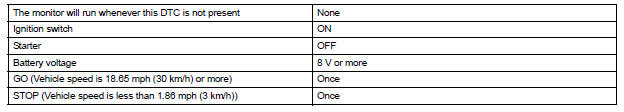

This DTC indicates that the stop light switch remains on. When the stop light switch remains ON during "stop and go" driving, the ECM interprets this as a fault in the stop light switch and the MIL comes on and the ECM stores the DTC. The vehicle must stop (less than 2 mph (3 km/h)) and go (19 mph (30 km/h) or more) 5 times for two driving cycles in order to detect a malfunction.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

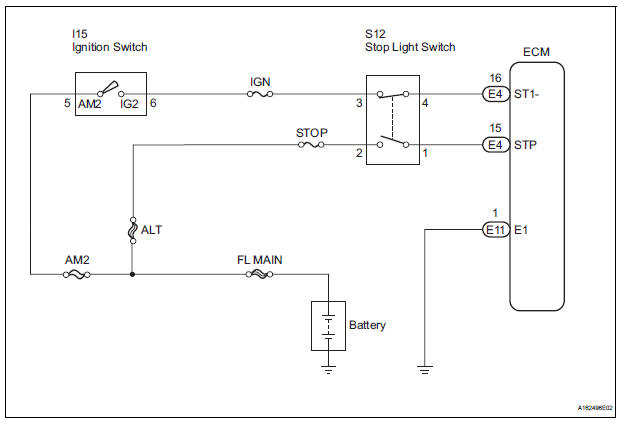

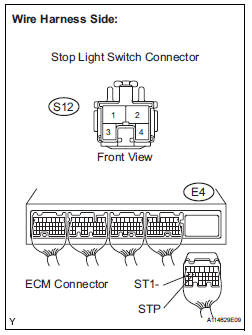

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

1 CHECK OPERATION OF STOP LIGHT

(a) Check whether the stop lights turn on and off normally when the brake pedal is depressed and released.

OK: Stop lights turn on when brake pedal is depressed.

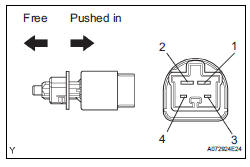

2 INSPECT STOP LIGHT SWITCH ASSEMBLY

(a) Remove the S12 stop light switch assembly.

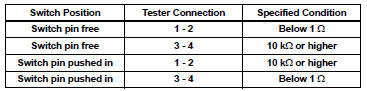

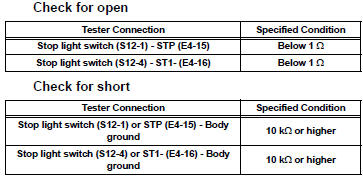

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

(c) Reinstall the stop light switch assembly

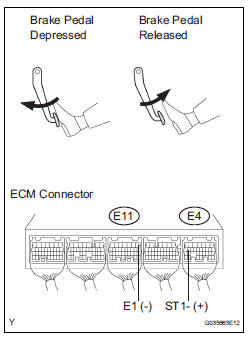

3 READ VALUE OF INTELLIGENT TESTER (STP SIGNAL AND ST1 - VOLTAGE)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the tester on.

(c) Select the following menu items: DIAGNOSIS / ENHANCED OBD II / DATA LIST / PRIMARY / STOP LIGHT SW.

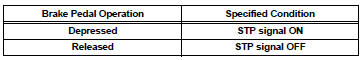

(d) Check the STP signal when the brake pedal is depressed and released.

Standard

(e) Measure the voltage according to the value(s) in the table below.

Standard voltage

4 CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH - ECM)

(a) Disconnect the S12 stop light switch connector.

(b) Disconnect the E4 ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance :

(d) Reconnect the stop light switch connector.

(e) Reconnect the ECM connector.

REPLACE ECM (See page ES-498)

Vehicle Speed Sensor "A"

Vehicle Speed Sensor "A"

DESCRIPTION

The speed sensor detects the wheel speed and sends the appropriate signals to

the skid control ECU.

The skid control ECU converts these wheel speed signals into a 4-pulse signal ...

Idle Control System Malfunction

Idle Control System Malfunction

DESCRIPTION

The idling speed is controlled by the ETCS (Electronic Throttle Control

System). The ETCS is comprised

of: 1) the one valve type throttle body; 2) the throttle actuator, which

op ...

Other materials:

Installation

1. Connect inlet sub-assembly

(a) Connect the inlet hose to the radiator.

(b) Install the inlet sub-assembly to the radiator with the

bolt.

Torque: 7.1 N*m (72 kgf*cm, 63 in.*lbf)V

2. Install no. 2 Radiator support

(A) install the no. 2 Radiator support to the radiator with

the 2 ...

Installation

1. INSTALL CENTER REAR SEAT LAP TYPE BELT

ASSEMBLY (for 8-Passenger)

HINT:

Refer to the instructions for reassembly of the rear No. 1 seat assembly (for

center seat).

Install the center rear seat lap type belt assembly

with the bolt.

Torque: 42 N*m (430 kgf*cm, 31 ft.*lbf)

2. I ...

Trailer Tongue Weight

A recommended tongue weight varies in accordance with the types

of trailers or towing as described below.

To ensure the recommended values shown below, the trailer must

be loaded by referring to the following instructions.

Tongue Weight

The gross trailer weight should be distribute ...