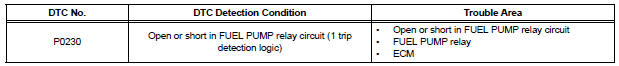

Toyota Sienna Service Manual: Fuel Pump Primary Circuit

DESCRIPTION

- This DTC is designed to detect a malfunction in the fuel pump (FUEL PUMP) relay circuit. When the system is normal, the battery voltage is applied to FPR terminal of the ECM while the FUEL PUMP relay is turned OFF. If the battery voltage is not applied to the FPR terminal while the FUEL PUMP relay is OFF, the ECM interprets this as a malfunction. The ECM then illuminates the MIL and sets a DTC.

- The FUEL PUMP relay switches the fuel pump speed according to the engine

conditions. The fuel

pump operates when the ECM receives the starter-operating signal (STA) and

crankshaft-rotating

signal (NE). The FUEL PUMP relay is turned ON while the engine is idling or

operating at low load.

This causes current to flow through the fuel pump resistor to the fuel pump. The fuel pump then operates at low speed. The FUEL PUMP relay is turned OFF while the engine is cranking or operating at high load. The fuel pump then operates at normal speed.

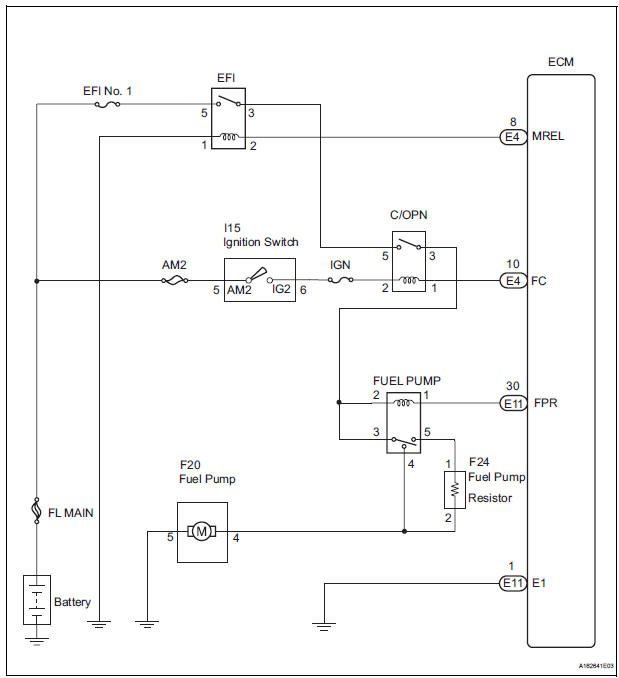

WIRING DIAGRAM

This troubleshooting procedure is based on the premise that the engine is started. If the engine is not started, proceed to the problem symptoms table (See page ES-27).

INSPECTION PROCEDURE

1 PERFORM ACTIVE TEST BY INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the intelligent tester ON.

(c) Enter the following menus: DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST / FUEL PUMP SP CTL.

(d) Check the operation of the relay while operating it using the intelligent tester.

OK: Operating noise can be heard from the relay.

2 INSPECT RELAY (FUEL PUMP RELAY)

(a) Remove the FUEL PUMP relay from the engine room junction block.

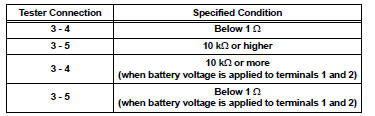

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

(c) Reinstall the FUEL PUMP relay.

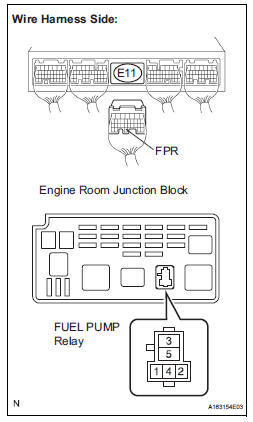

3 CHECK HARNESS AND CONNECTOR (FUEL PUMP RELAY - ECM)

(a) Remove the FUEL PUMP relay from the engine room junction block.

(b) Disconnect the E11 ECM connector.

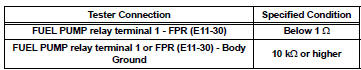

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance

(d) Reconnect the ECM connector.

(e) Reinstall the FUEL PUMP relay

REPLACE ECM (See page ES-498)

System Too

System Too

DESCRIPTION

The fuel trim is related to the feedback compensation value, not to the basic

injection time. The fuel trim

consists of both the short-term and long-term fuel trims.

The short-ter ...

Random / Multiple Cylinder Misfire Detected

Random / Multiple Cylinder Misfire Detected

DESCRIPTION

When the engine misfires, high concentrations of hydrocarbons (HC) enter the

exhaust gas. High HC

concentration levels can cause increase in exhaust emission levels. Extremely ...

Other materials:

Throttle Actuator Control System

DTC P2111 Throttle Actuator Control System - Stuck Open

DTC P2112 Throttle Actuator Control System - Stuck

Closed

DESCRIPTION

The throttle actuator is operated by the ECM, and opens and closes the

throttle valve using the gears.

The opening angle of the throttle valve is detected by the Thr ...

Terminals of ecu

1. Terminal of ECU

(*1): Models with dynamic laser cruise control

(*2): 2WD model

2. Terminal Inspection

(a) Disconnect the connector and measure the voltage

or resistance on the wire harness side.

HINT:

Voltage cannot be measured with the connector

connected to the skid control ECU ...

Installation

1. INSTALL REAR NO. 2 SEAT ASSEMBLY

Lock the seat leg rear to the floor striker.

Lock the seat leg front to the floor striker.

Install the rear No. 2 seat assembly with the 6 bolts.

Torque: 19 N*m (194 kgf*cm, 14 ft.*lbf)

NOTICE:

Tighten the bolts in the order sho ...